Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- How can I add H parameter in th sheetmetal

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How can I add H parameter in th sheetmetal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How can I add H parameter in th sheetmetal

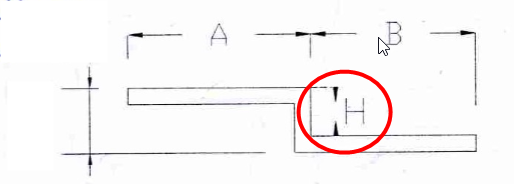

It has the default parameter in the Creo sheetmetal. (Example : R is radius , T is material thickness)

But I need to add the parameter that is H. (H is Height)

Refer the picture

How can I add the H in the Sheetmetal Bend Table

Because I have the formula that use the H and I don't know how can I set it.

When I was bending it (the Z form sheetmetal) twice , the developed length was wrong.

I Need to use our formula , including H , to compute the developed length is correct.

Please help me add the H in the sheetmetal

Thank you for your reply

My English isn't very good, please don't mind.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Sheet Metal Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am sorry, but I don't understand. You need to add a model parameter H? To where?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The flat pattern depends on your bend radii and material thickness. The offset height is just added material to get the final length.

The software will handle that value no matter how you input it.

Your model does not show radii for the bends, but square corners. That will not work for the flat pattern generation routines.

Redesign the part with proper bend radii and then recalculate the flat pattern. If the flat length is still wrong, adjust the Y-factor (K-factor) for the stretching of the forming operation.

There are many documents that explain this. I like the article by Olaf Diegel called Bendwork. It is a downloadable PDF on the web.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, Ben Loosli & Tomas Loun

Thank you for your replay.

Maybe I need to look for other method.

Because The offset is make once. It's not bending twice.

Their manufacturing methods are different

So the bend formula is not suitable for the offset.

I found that Creo couldn't have any function for sheetmetal offset so that it couldn't define H parameter.

Thank you

I will try other method

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The offset being made as 2 bending operations or a single die press should not substantially alter the flat pattern length. You still need to account for the stretching of the material through the bends.

You may need to adjust your K-factor value for the software to get you the desired flat length, but that should be easy with a few trial parts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you

I will try K-factor or bend table.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can create sketched seams (user-defined flange) that will allow you to include the H dimension.

Typically, this is a joggle die. There is deformation that Creo does not account for.

Manufacturers often have to adjust the pattern, or there remains sufficient tolerance to not worry about the deviation.

In general, the control of the K or Y factors appropriate for the tooling used for the project is sufficient for flat pattern layouts.

There are also punch and die features that do not add to the developed length.

These are intended for metal deformation and do not change the developed lengths.