Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Mechanism Sliding Fit Interaction

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Mechanism Sliding Fit Interaction

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mechanism Sliding Fit Interaction

Hi all,

This is my first post on this community forum, so I apologize in advance if I'm missing anything!

I am working on an assembly where I have two parts that fit together with a small gap of 0.05mm. I am attempting to use the Mechanisms in Creo (which are apparently tedious to use in Creo compared to SW). I am using a 'Slider' constraint between two said components. I have attached a zip with part and assembly files.

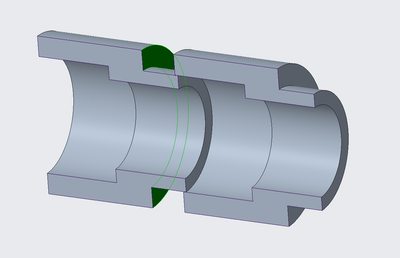

The problem I am having is that despite with a 0.05mm gap, it seems like Creo thinks the parts are touching when they are not. What I mean by this is in the image below, you would think the surface highlighted in green would be flush with the one next to it. However, when I drag the components together, this is as close together as they can go!

I have no clue why this is happening. I assume it's probably some setting that I did not know to change. Any help would be appreciated!

I have tried changing the diameters around, and I've found that making the gap between the two larger results in me being able to drag the components closer to be considered flush with one another.

Thank you!

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @JiffiPop , @kdirth & @MartinHanak

Just illustrating what I documented above in little movie below for future reference if needed, and to hopefully grant a better understanding of what I meant.

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The second part moves fine for me in the assembly supplied. The only thing that I see missing is setting some limits on the movement and a regen value if desired.

I am not sure what you are expecting. In the slider mechanism connection, the translation constraint does not snap to 0. You have to enter the desired position and set the movement limits.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I did leave limits and regen value out for the example. Below I have uploaded a video to clearly explain my issue. My question is why will the parts not drag together so they touch?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can't see you video.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It took awhile to be approved. The video should be viewable now.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ensure that you translation limits are correct. Also, if Set Zero Position has been pressed, 0 may not be at contact position.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The zero position is at the contact position. It gets stuck at around -3.35400 mm. The problem is not the limits, or the zero position. It seems rather that it is setup correctly, I just cannot drag it there. Perhaps this is a bug in Creo? It seems the only way to move it to 0.00000 mm is by manually inputting this number in the 'Translation Axis' portion of the slider constraint.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Without a model exhibiting the behavior, it is difficult to determine the issue. Additional parts before and after it in the model tree may be affecting it.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, I uploaded a zip file in the original post that has the issue, and a video of the issue in the aforementioned assembly. It's not additional parts before and after in the model tree because it is an isolated incident that I even recreated in the assembly with only two components.

The only issue seems to be with the dragging feature only when using the mouse. I can type in to move it to position 0 mm, of course. However, this is really not ideal in terms of Creo's functionality.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @JiffiPop

At the begining, starting without config.pro, I was unable to reproduce the issue. I nevertheless confirm that issue:

- Begins to occur as long as enable_advanced_collision is set to yes (default is no)

- Can be resolved when above option is enabled, as long as you configure a high value for mdx_collision_num_triangles (for instance 6000, instead of 1000 being the default)

Background: When enabling advanced collisions, the models are somehow "meshed" to check when collision occurs. Here, your external diameter is 15.7863 inches whereas your internal one is15.7375 inches (very close to external therefore). In such demanding conditions:

- the default number of triangles (1000) generated for MDX is not enough, because diameter are somehow "roughed" and system interprets there is a collision (whereas there is none in the reality).

- To resolve this, you need therefore to increase the number of triangles to detect collsions, hence the reason why mdx_collision_num_triangles 6000 is able to produce a better handling of this specific use case

Note: the default value 1000 is largely enough for the very large majority of use cases. We suggest to keep it as a default to avoid performance issues in larger assemblies, and just modfy it to 6000 if needed in some very specific situations (like this one).

Hope this helps to understand what occurred, why it occurred, and how to avoid this issue in the future.

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @JiffiPop , @kdirth & @MartinHanak

Just illustrating what I documented above in little movie below for future reference if needed, and to hopefully grant a better understanding of what I meant.

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you, Serge! This is the solution! I appreciate your input! 🙂