Community Tip - Have a PTC product question you need answered fast? Chances are someone has asked it before. Learn about the community search. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Parallelogram mechanism with limits

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Parallelogram mechanism with limits

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Parallelogram mechanism with limits

Hi guys,

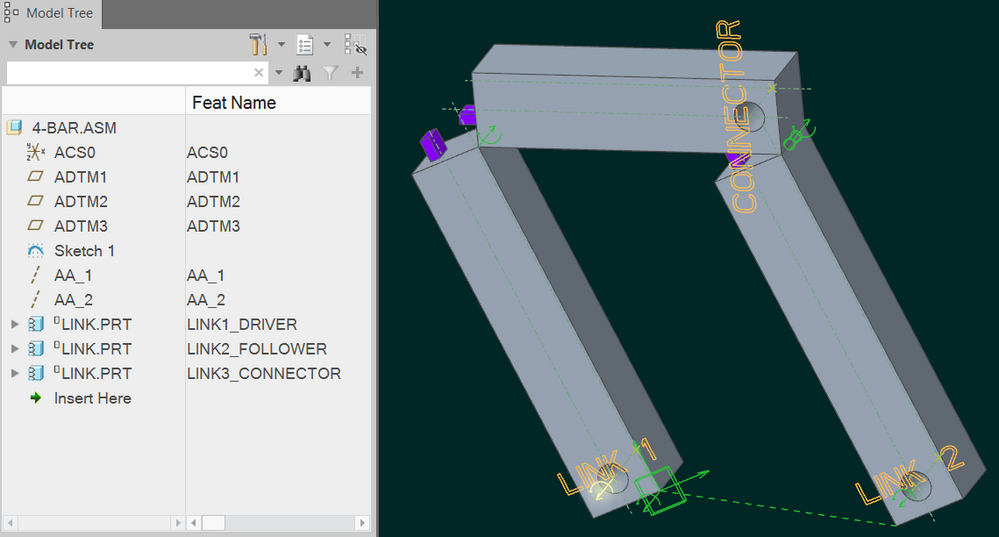

I'm creating a parallelogram mechanism in Creo 3 and I'm struggling with the limits of this mechanism.

I was able to connect all "links" correctly with pin and cylinder connections. But now I also want to add some limits and I don't want to integrate some minimum and maximum angles in one of the links (with the “rotation axis”), because the limits can change when the width of the links are changing. What I want to do is putting in the real limits by a minimum distance of zero mm between two surfaces. The only problem is that I don’t know which connection I can use for this.

Can somebody help me with this?

Here you can see what I mean:

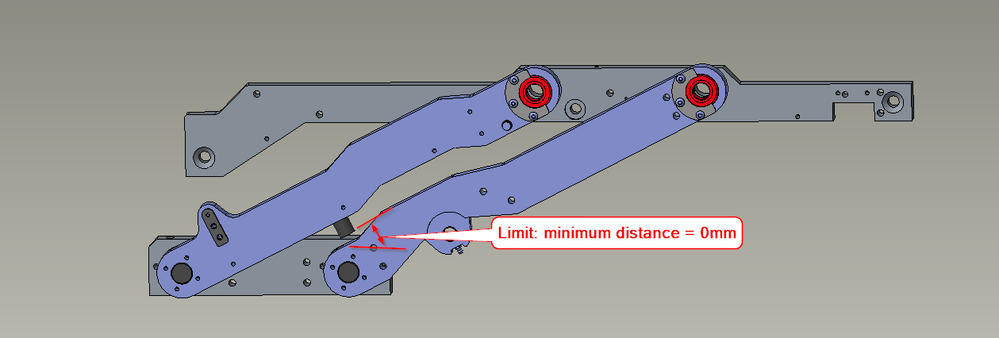

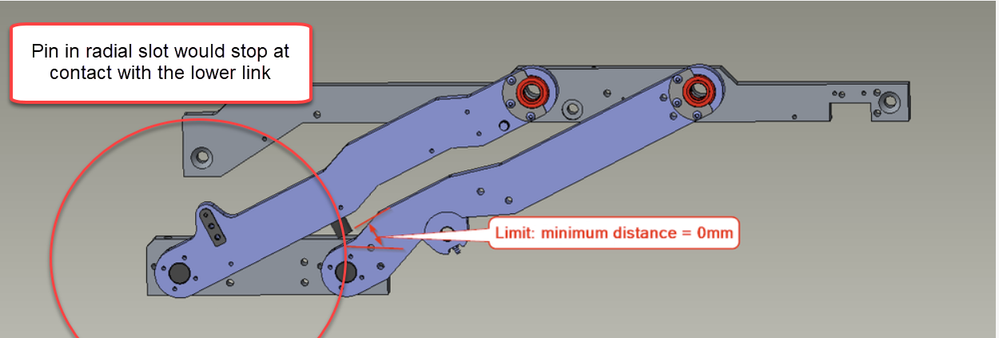

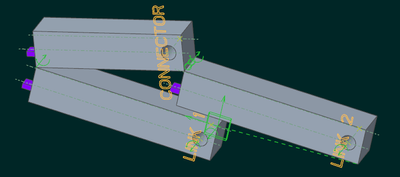

The mechanism has in its left position a limit of 0mm.

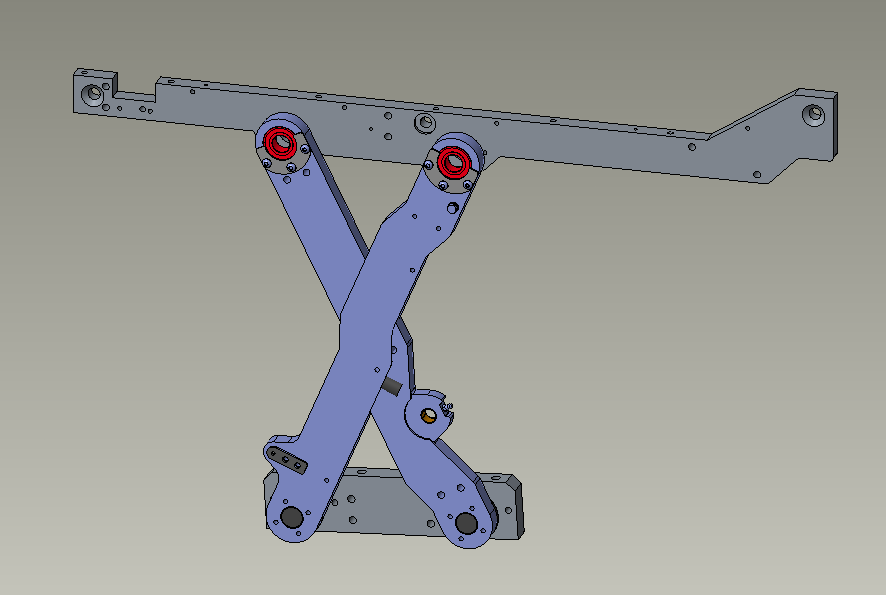

The mechanism has in its right position a limit of 0mm too:

Another thing what is happening with this mechanism, is that the links get crossed while moving it. I hope this can be solved with these limits too.

In attachment you can find the assembly and the parts I'm working with.

Solved! Go to Solution.

- Labels:

-

Assembly Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

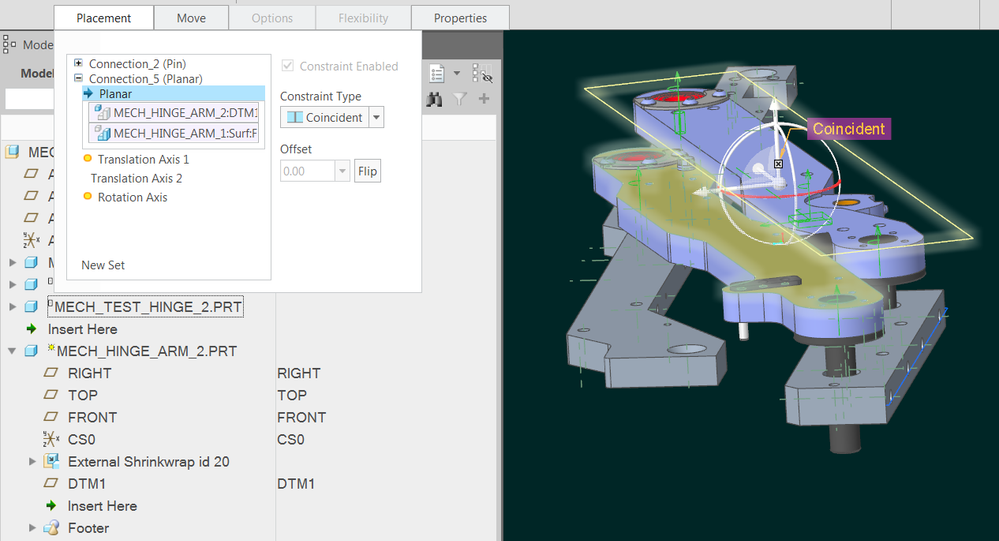

I opened your file and made it work by:

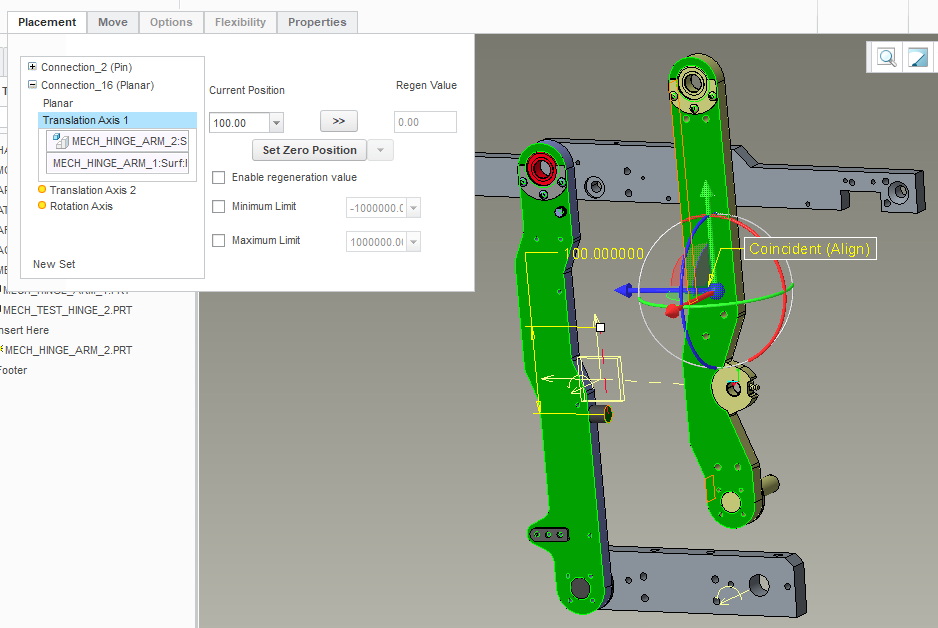

1) adding a plane in MECH_HINGE_ARM_2.PRT that is offset by 5mm from the part's large front surface - this plane is coincident with the front surface of the other blue MECH_HINGE_ARM_1.PRT. I'm not sure if that is necessary, but in my experience, coincident constraints behave much better than the "distance" type.

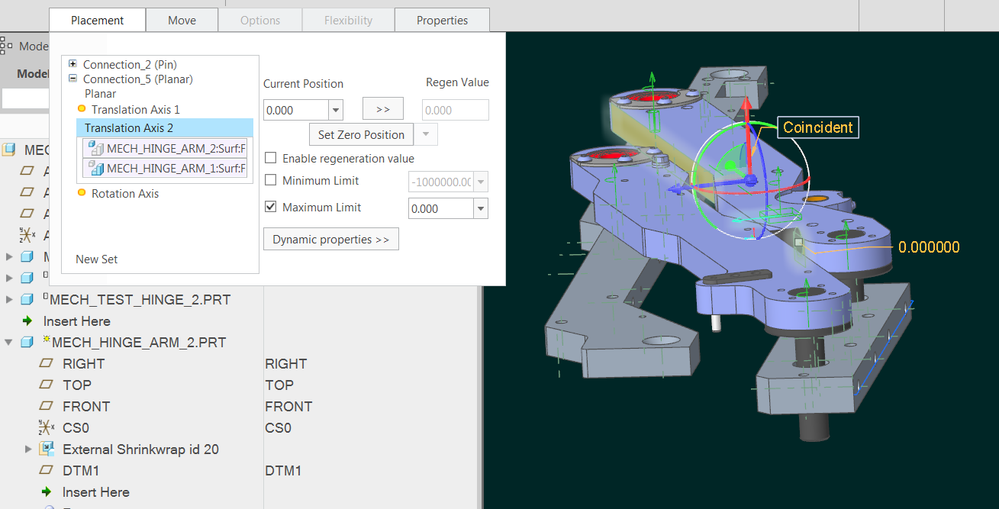

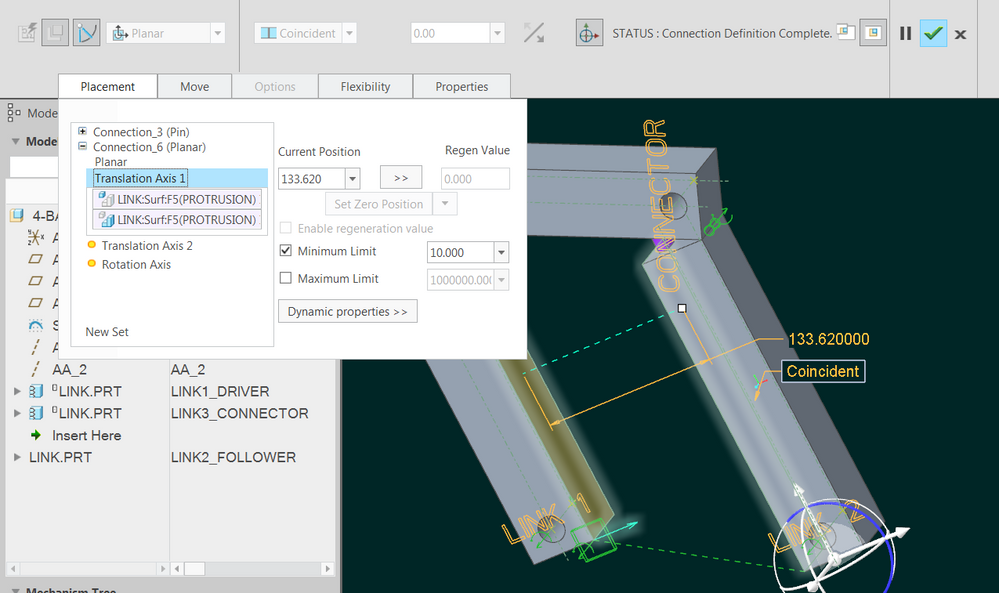

2) Planar connection made using translation axis 2... Using translation axis 1 didn't work as the limit dimension was in the "wrong" direction (u instead of v, so to speak...) Also, the dimension produced by the system was -ve, so max limit had to be imposed to make the limit condition when the reference surfaces touch:

Not sure what to to tell you - with Creo, it doesn't always make sense and you have to try few things before it works...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you want to handle this without writing relations and creating analysis features, you can work it out graphically. Have you considered adding a slot mechanism for kinematic purposes to limit this movement? This will constrain the rotation DOF of the assembly. If you were to use a motion skeleton you can add the slot/follower mechanism that would constrain the motion based on the linkage geometry so it will update with linkage changes. This slot mechanism would be used for kinematic control only and would not include solid parts in the assembly. The slot geometry would regenerate based on the linkage layout and would update when the motion skeleton regenerates. The ends of the slot would impose the limit positions of the assembly as desired. It appears that you would be able to easily define this with some datum curves in a motion skeleton.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the answer tbraxton!

Only thing is, I don't know how to integrate this slot mechanism... I have to select a "point on line". But which point and line do I have to select.

I haven't worked with motion skeletons, so maybe I first have to figure out how this works...

Or is there a possibility that you change the assembly I have added to my first post. Than I can see how to do this...

Regards!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I assume that one of the blue links shown in your mechanism already has a "pin" type of connection.

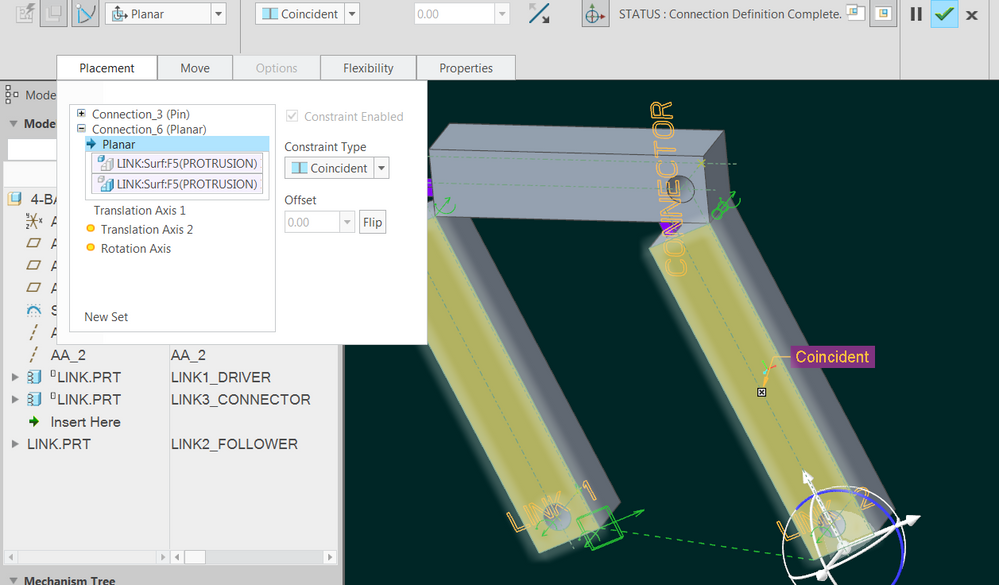

Add another connection to this link, this one of type "planar". This planar connection will be kinematically redundant as it will specify that the blue links must move on a common plane (you might need to define this plane in the link parts if it doesn't coincide to the physical bearing surface, e.g.)

Anyway, the planar connection will also allow you to specify how close a set of faces perpendicular to this plane (one on the follower and the other on the driver) will be allowed to get.

Example (note: I've cobbled this together from a very generic "Link.prt" model I had and I used the same model but assembled it as 3 flexible components, varying their length and description text. Also note that the link components are joined by pin / cylindrical joints which use their blocky edges for axis definition):

Motion is limited to the zone where the driver and follower links are parallel and cannot cross-over because they cannot get closer than 10mm away from each other. Extreme positions:

1)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi pausob,

thanks for this reply. This is indeed what I want to achive, but the problem is that when I add the "Translation axis 1" in the planar connection, this is giving me a dimension which is parrallel and not perpendicular to the surfaces which I'm selecting. So this is doing some real strange things...

Any idea what I'm doing wrong?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I opened your file and made it work by:

1) adding a plane in MECH_HINGE_ARM_2.PRT that is offset by 5mm from the part's large front surface - this plane is coincident with the front surface of the other blue MECH_HINGE_ARM_1.PRT. I'm not sure if that is necessary, but in my experience, coincident constraints behave much better than the "distance" type.

2) Planar connection made using translation axis 2... Using translation axis 1 didn't work as the limit dimension was in the "wrong" direction (u instead of v, so to speak...) Also, the dimension produced by the system was -ve, so max limit had to be imposed to make the limit condition when the reference surfaces touch:

Not sure what to to tell you - with Creo, it doesn't always make sense and you have to try few things before it works...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi pausob,

thanks for your quick reply and your help. Indeed, working with "Translation Axis 2" instead of "Translation axis 1" was solving the problem !!!

This is realy what I was looking for.