Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- Analysis

- "Some connections between surfaces have been ignor...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

"Some connections between surfaces have been ignored"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

"Some connections between surfaces have been ignored"

I'm trying to analyse a shaft with various components assembled on it.

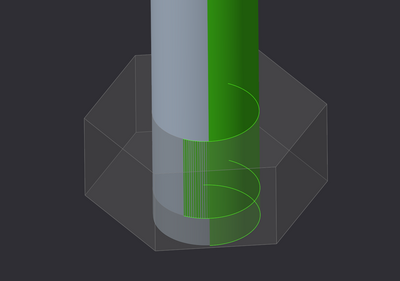

One of those is a nut, which I've represented by a simple part, with a bore which sits on the OD of the 'thread' location on the shaft. The 'nut' bore sits entirely within the shaft thread OD surface; they have equal diameters and are concentric (assembled using these surfaces).

I've set the default interface to Free, and created a Bonded interface between the two parts. There are Contact interfaces between other pairs of parts.

When I run the analysis it reports "Some connections between surfaces have been ignored" and highlights the Bonded interface. It provides this link:

which is no help whatsoever. The analysis then fails because it's insufficiently constrained... because it's decided to ignore one of my boundary conditions!

Why is it doing this? Any suggestions?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Jonathan

Could you provide a picture, please? In addition, are you using Simulate 2.0 or a higher version?

I had (and still have) some problems involving contacts and in some model I also had this same warning - the consequence was indeed that the contact was ignored during simulation.

Mostly problems were related with the contact geometry. Sometimes creating a volume in the contact was enough to overcome the problems. Sometimes the bottom–top hole with slightly different dimensions (or a small recess) helps. In other cases the work around was found by chance.

I have even put some examples in the PTC community (as in your topic “Getting fasteners to work”).

Regards

R. Rabe

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think this might be your issue with the bonded connection. The same things happen with spheres, cylinders, and other geometry.

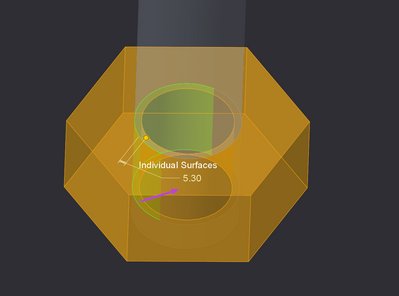

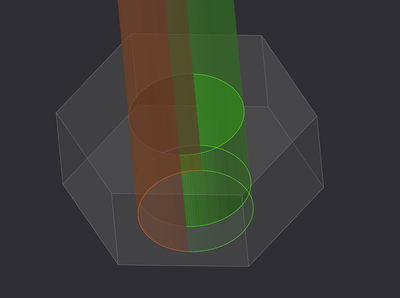

Try growing the nut ID smaller than the shaft then use [GET Data] merge/inheritance - CUT the shaft out of the nut.

There are other ways to do this of course, the problem is that the surfaces like to be exactly the same for bonded interface.

I would also consider suppressing fillets touching the merged area that create difficult meshes. Or you can replace them with a similar chamfer, which will work better.

Also... it helps to make part and assembly tolerances all the same absolute tolerance, for example 0.01mm absolute, is mandatory for majority of my work. These are enforced by start parts and import profiles. Easy to check in SIMULATE - TOOLS - Tolerance Report

incompatible surfaces

offset to allow cutting

cut so surfaces now compatible

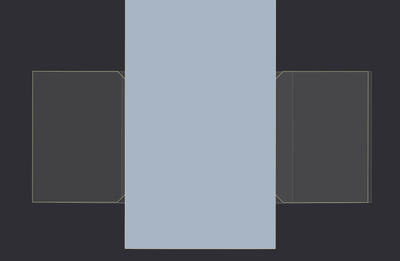

undesirable fillets/tangents (these are good for contact but bad for bonded)

better replaced with chamfer

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the replies!

The mis-matching 'half-cylinders' was a really good suggestion, but as far as I can tell the surfaces are perfectly aligned (the vertices are offset only along the axis of the parts, with a projected distance of 0.000000 in the other directions.

My shaft did have a different tolerance, at 0.0012 relative with everything else being 0.01 mm absolute. Fixing that hasn't prevented the connection being ignored.

The interface between the surfaces is pretty simple and sharp-edged (picture removed for now as it won't let me post).

HOWEVER: having tried creating an assembly cut and a surface region to generate coincident surfaces, I've realised / discovered that the analysis is completing anyway, and the interface is behaving as expected / desired (even reporting out a force).

WTH, PTC?