Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: A problem of Double-headed screw

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

A problem of Double-headed screw

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A problem of Double-headed screw

Hi all

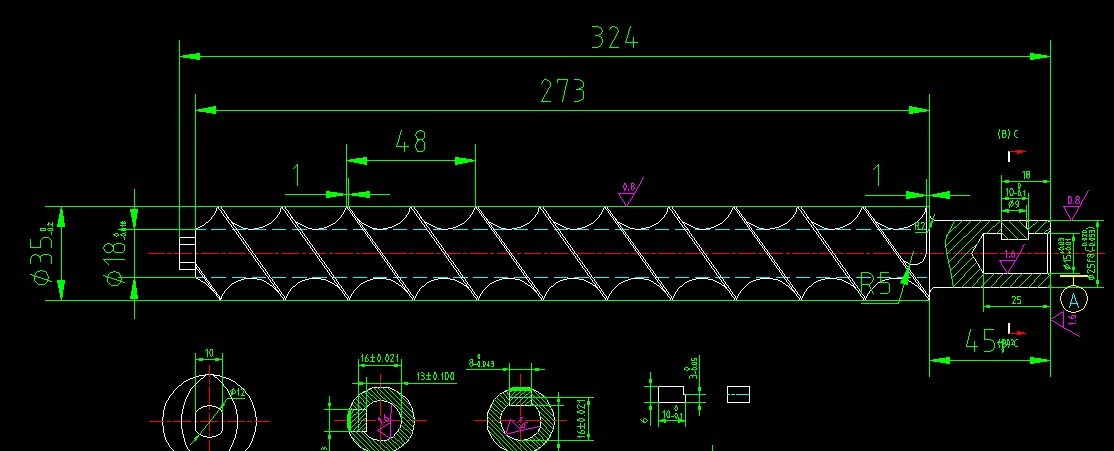

Here is a 2-dimensional drawings.I try to make it into a three-dimensional,

but unsuccessful,

Anybody have experience on this! Plz help me.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

2D Drawing

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No one ?![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Could you tell us, what your problem is exactly ?

Did you not manage this spiraled loft or are you missing functions for it ?

SolidDesigner-20.5 + PE8 + PhoenixPDM + Solidworks + Blender

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I used with VSS,but unsuccessful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is what I want.![]() Thanks!

Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Blue_Duncan,

I have a video Tutorial showing one way of modeling the threads. In this toturial, i created a 4X thread Bit. There`s also the Helical function in Proe that may serve its purpose in these kind of situation but i personaly prefer the method illustrated in the video... Here it is: http://www.youtube.com/watch?v=6DdjyF7b8oE

Tell me what you think and good luck.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Just tried this method and it works better than the helical sweep. The geometry construction I used tends to cause some slow down when creating the solidify feature.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I should add that the method illustrated in the video creats a kind of distorted cut... just like having a Warp feature doing it instead. The cut is not circular. You can see this effect if you increase the amount of turns.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can not link to your website.![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can not link to your website.Pass me the video files,please.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I cannot attach the video file in the email because its to big so i posted it on rapidshare. Here`s the video download link... try that:

http://rapidshare.com/files/401276735/Bit_tutorialForMCAD.mp4.html

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

Its really simple.just click on Autobildz tab in detailing mode.

if your Autobildz tab is not highlighted you need to do some configuration setting

enable_autobildz configuration option.

and see how easy is to create 3D-model from 2D-drawing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I do not know how to do what you said.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here are some more files showing some different ways of creating this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Does are very good examples. thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You are a warmhearted man ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

sd5=7.75*360*trajpar How to get the dimension 7.75 ?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

the value 7.75 is arbitrary. It depends on what angle you whant the helical feature to stop at.

For exemple:

for ---7.0 * 360 * trajpar ---

At trajpar = 0 (begining of sweep) the angle reference is zero (7.0 * 360 * 0)

At trajpar = 1 (end of sweep) the angle is still zero (7 * 360 * 0 = 7 full turns, hence zero degree to its original reference)

for ---7.75 * 360 * trajpar ---

At trajpar = 0 (begining of sweep) the angle reference is zero (7.0 * 360 * 0)

At trajpar = 1 (end of sweep) the angle is at 270 degrees (7.75 * 360 * 0 = 7 full turns and 3/4 (270), hence 270 degrees to its original reference)

From what i can assume from Kevin's work is that he wanted the helical sweep to end at a given angle (270 degrees relative to its begining of curve angle)

for some reason i can't put the image directly in this message. I have attached a image illustrating what i'm saying with the exemples

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

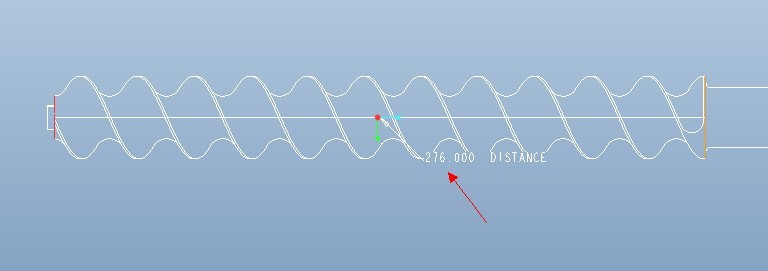

Going back to your original drawing there is enough information that the 7.75 isn't completely arbitrary. Removing the shank length the thread length is 279 (I assume mm). Defining the VSS through the ridge of the first thread and using the lead value you specified on your drawing, the ridge distance of the first thread is 48 mm in one revolution. If you you start at the first ridge the thread length is 278 mm. Dividing 248 by 48 gives 5.792 revolutions. Noticing that the thread doesn't go all the way to the end I chose 5.75 as the number of revolutions which is 276 mm in length. Because of the section I used I needed to extend the sketch for the origin trajectory so the cuts extend through the entire length. I chose to extend the trajectory 1 lead length (48 mm, 1 revolution) at each end so the number of revolutions needs to be 7.75 to make the lead for the screw correct. Another way to do this is to replace the 7.75 in the relation by the length of origin trajectory/lead length which should give the same value and you wont have to worry about updating the value manually if you change the length.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Could you make it into a video format? VSS unsuccessful

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

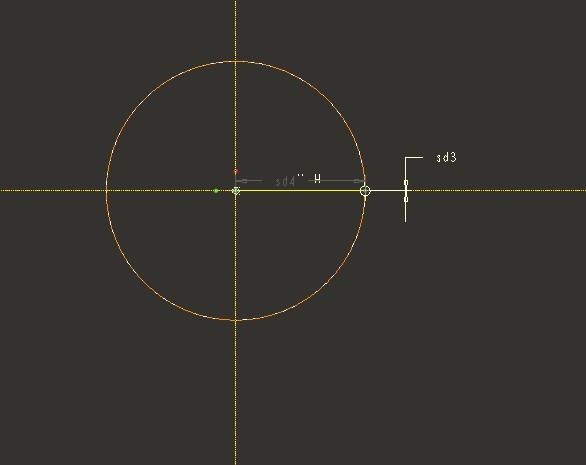

Unfortunately I don't have the software required to make a video. For the first VSS (from the picture it looks like that's the one you are refering to), the one used as the X-trajectory, if you have created the section and entered the relation are you getting a flat surface? If so check the options tab and make sure it is set to variable section. Jaques-Michel shows how to create it in his video. The only other thought I have is is that a construction circle or are you using a cylinder surface as a reference? If the latter, it appears you may have additional geometry (two lines) that is preventing a regenerable section. If the end points are at the center and the other on the circle as you have shown in the picture there should only be an angle dimension (sd3).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Wrong 。The original value is 273.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I had to make some assumptions because not all the information you show in your pictures came through. When I initially opened the dwg you posted some information is missing when I import the drawing. Here is what I get. The 273 dimension does not show up. Although I could have gotten the dimension by adding a created dimension I didn't think to try that since there was no indication of scale.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Kevin,

Could please attach the zipped file again? I could not unzip it. I ge the message that it is part of othe file

Gautam

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can upload it again but it will be a couple of days before I can. I did try the files again and had no problems opening them. Another thing you may want to try in the meantime is select the file, right click, and choose explore. This should open the zip file in windows explorer and you should be able to extract the files that way.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is a new upload to see if you can open.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How do I contact you? Can you tell your contact details? Such as MSN account?