- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Flatten round bottom bag

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Flatten round bottom bag

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Flatten round bottom bag

Hi,

I need to design a cylindrical bag with a hemispherical bottom. The diameter of the bag is 400mm and the bottom has a 180 hole in its centre. Having contacted the company making it, they want a flat model that they can use as a stencil and cut out the fabric. How do I make this happen? I was thinking that the Sheet metal module would be good but I can't seem to make it work. Also done it in the standard mode as a flat part with half "orange peel" shapes on the bottom but how can I fold it together, with the bottom so all connect properly.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

http://en.wikipedia.org/wiki/Developable_surface

http://en.wikipedia.org/wiki/Euclidean_metric

Please use approximation - since you live in Euclidean metric space.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello, Erik.

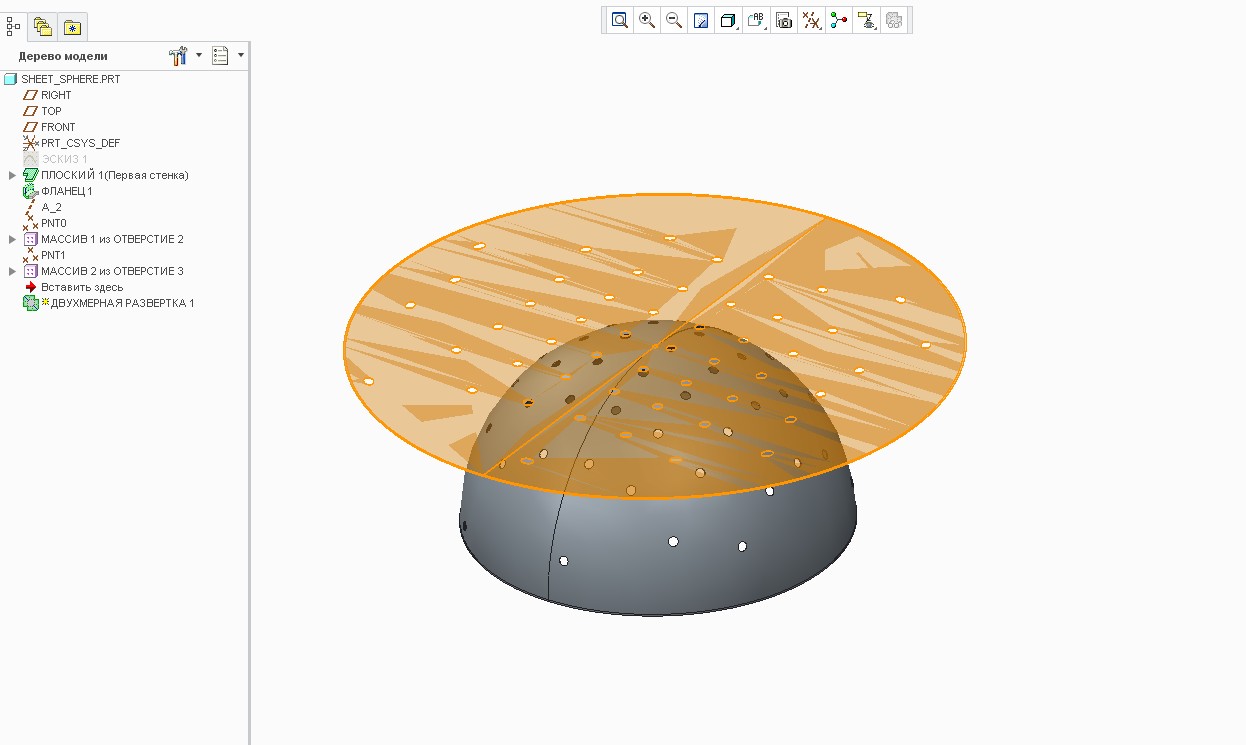

I have managed to make a flat pattern of a hemispherical bottom by using a flange tool.

I just made a small round flat wall and then added a flange to it with a demanded radius.

In your case it should be 200 mm.

If you want to add some holes on this bottom you should use a filled pattern or just add them on the unbended part and then bend it again.

I hope it would help you.

Best Regards, Vladimir.

P.S.: It looks as if I've just discovered the fourth dimension thanks to Creo Parametric ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for the assistance.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok Vladimir,

now please show me how do you do this with some real object like piece of paper without ripping or dents. Create a footboll using two A4 papers and post a picture. ![]()

It has been possible for a quite some time to use either flange tool, die/punch or flatten quilt&bend solid to create shapes that are not develovable - and still get a "flat state" of object. This flat state does not take in account any deformation nor plasticity - and therefore results are out of this world.

A simple proof - the circumference lenght of your flat state result will be larger than circumference of ball. Where do you put the extra material without any dents?

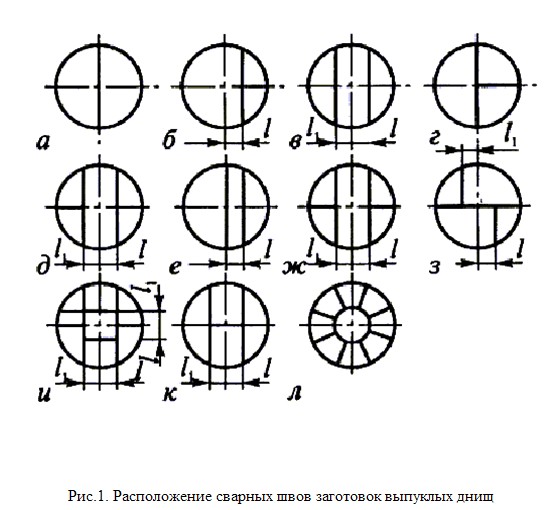

When it comes to textiles - you may strecth & compress fabric a bit and get somekind approximation of sphere using pieces. Think about footboll as an case.

http://en.wikipedia.org/wiki/Truncated_icosahedron

http://www.youtube.com/watch?v=5HNJB0vMq6w

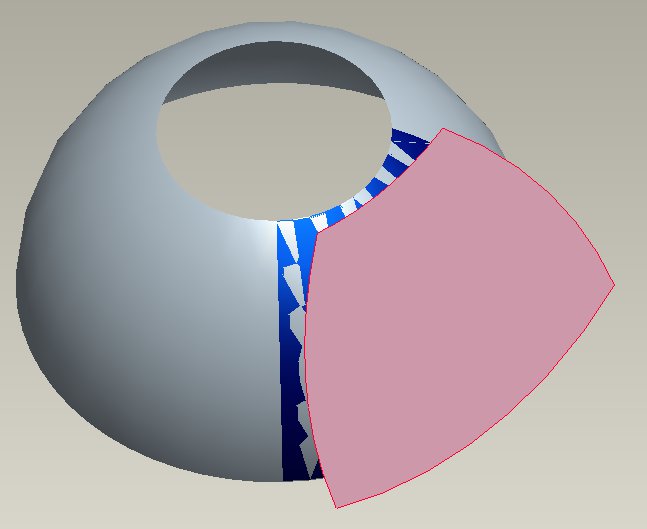

So, using flatten quilt feature would get you closer to your goal:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Easy - using plastic deformation and ductile material you can form a spere from plate - but if fellow here wants to have solution with no plastic defomation (he was using fabric)....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Oh, yeah, Mikko! Of course you're absolutely right!

I should have studied better at my English classes ![]()

Now I understand that fabric is cloth produced by weaving or knitting textile fibres.

Sorry for misunderstanding.

Kind Regards, Vladimir.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No worries mate,

at least we managed to have a proper discussion about modelling possibilities with various cases.

Yours, Mikko

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi. Yes the fabric that I'll be using is nonstretch. What I ended up doing, which is probably considered the "ugly" way is that I made the bag in 3d, then cut it into 10 slices. I then measured the lengh of each side, the surface measured height and then made a new part with these dimensions. Ugly but it worked.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The hot air balloon guys come to mind. In Creo, you can cut up the sphere and flatten the quilt of one of the segments. Since there will always be some level of deformation due to the nature of turning something linear into something spherical, you have to decide how many segments you want the supplier to join. The finer the "mesh" or segmenting, the closer you will come to a true sphere. I don't think Creo will tell you how much "fudging" it does to flatten a quilt. A manual grid mapping exercise may yield better results... or at least do both and compare for a sanity check.

Funny, however that the manufacturer cannot do this on their own. Are we beginning to rely on CAD too much? Are the true artisans of the world all retired now? ...flying hot air balloons ![]()