Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Small changes too small?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Small changes too small?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Small changes too small?

Okay, I am getting annoyed!

I am trying to move a surface of an imported component by .001". Extrude is telling me I cannot move less than .003".

I work with inches and I work with micron scale details. What do I have to set to make this kind of change?

Seriously? Can't this software -at least- point me to what I need to set to make this kind of tweak to a part?

Solved! Go to Solution.

- Labels:

-

Surfacing

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Damn... have you ever seen the "Part Setup Menu" in Creo? I haven't either.

Answer: FILE/PREPARE/MODEL PROPERTIES/Materials/Accuracy and "change" this to Absolute and give it an appropriate value.

So config.pro may set the values, but doesn't activate the Absolute Accuracy toggle. It was -still- stuck at Relative regardless of the config.pro settings.

If you don't see this switch in the Model Properties menu, you might have to set enable_absolute_accuracy to yes in config.pro.

Seriously... I can see why PTC enabled relative accuracy... but to make it default? Argggg!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Accuracy to absolute 0.0002.

Guess you will need to fix the imported model then.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Didn't work. Still get the error message telling me my projection distance has the greater than .003".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok, what is the size of the surface you are trying to project?

Does it have degenerated points?

What kind of feature do you use to make the move?

Do you first make a copy of the surface before you move it?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

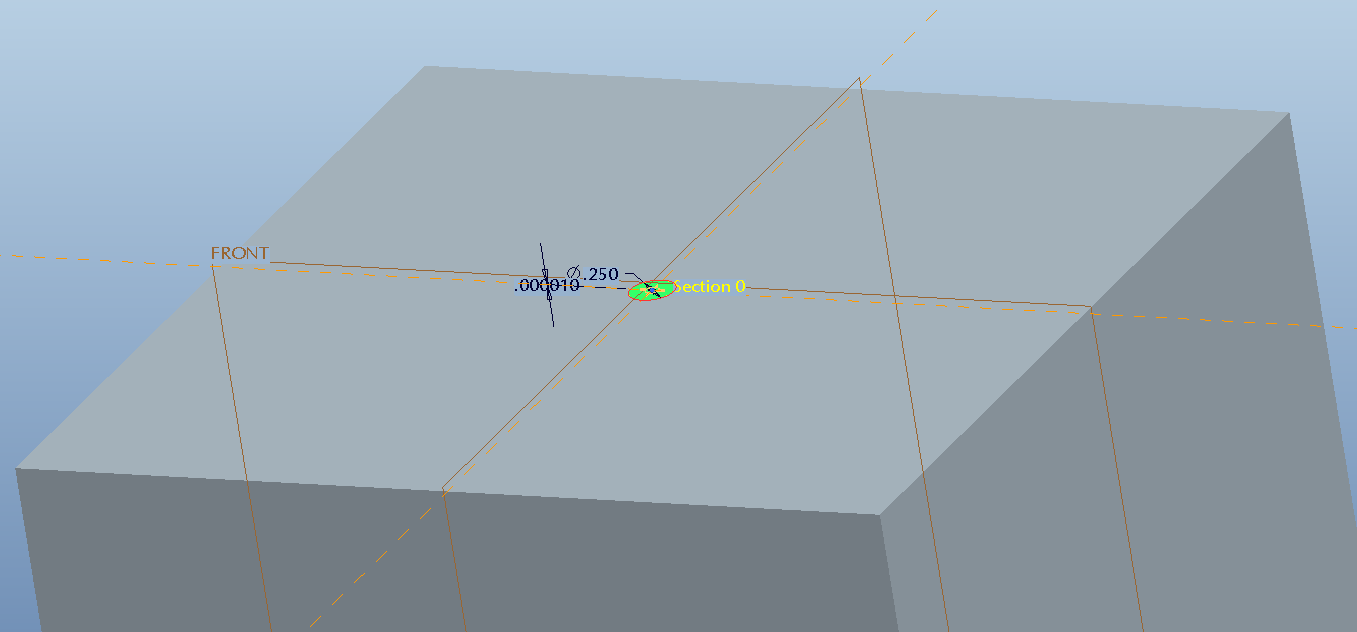

I am using sketching/project existing edges of two concentric circles. It does .003 fine but less I get the error:

I had a similar problem when I revolved a sketch instead where it ignored the .001" offset in the cut sketch but cut the opposite face just fine.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Antonius...

Set your accuracy as low as it will go and try it again. Try .0001 and regenerate. If that doesn't do it, you'll need to change the accuracy lower bounds in the config.pro settings.

By default .0001 is the lowest you can go... but for people who work with exceedingly small features, you may need to reset the lower accuracy boundary to be an order of magnitude lower. This can lead to longer regeneration times as with any increase to the accuracy. But, for times when you need it, there is a way to go LOWER.

Go into your config.pro options and set accuracy_lower_bound to be something like .00001 (5 decimal places). That will give you much, much finer accuracy controls and should resolve your problem.

I would only set a part accuracy this low when I absolutely HAD to, otherwise you're killing your processing power for no reason. Use it when required, otherwise try to keep your default accuracy of .0012.

Thanks!

-Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok, I think you can't do that small offsets in sketch features.

Try to avoid using sketcher to get the thing done.

I have to say I don't really understand the problem you have there. Would help if you could explain it further.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Looks to me like he's just doing a very small extrusion. I think the resetting the accuracy boundary will resolve the problem.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The problem is not sketcher, it is the basic functionality of revolves and extrudes.

I have set all the accuracy settings I could find to extreme levels and it still doesn't function.

I have a job that requires many small tweaks to imported models. I work with .0005" manipulation on a regular basis. These models are used for tool paths that demand accuracy. The parts fit within a 6" bounding box. I am not asking anything I wouldn't ask of any other system. I find it very disturbing that Creo would even consider ignoring a specific .001" surface in a revolved, or a protrusion of this size.

Accuracy to .0001 would fit the bill fine for me. Regen time for this has never been an issue. After all, the system uses .0005 for default. Something else is at play here and I don't know what it is.

I will probably have to make this a service call. I need to mess with some examples first. These particular models are .pkg files from CoCreate 13.

BTW: of course I have a work-around by filling in the feature and re-creating the cuts, but I shouldn't have to do that. I have similar problems with small angles.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have submitted this as a critical support issue. I just confirmed that this seems to have something to do with the bounding box size of the object. This issue propagates to all sorts of commands. Projection and revolve being the notable ones.

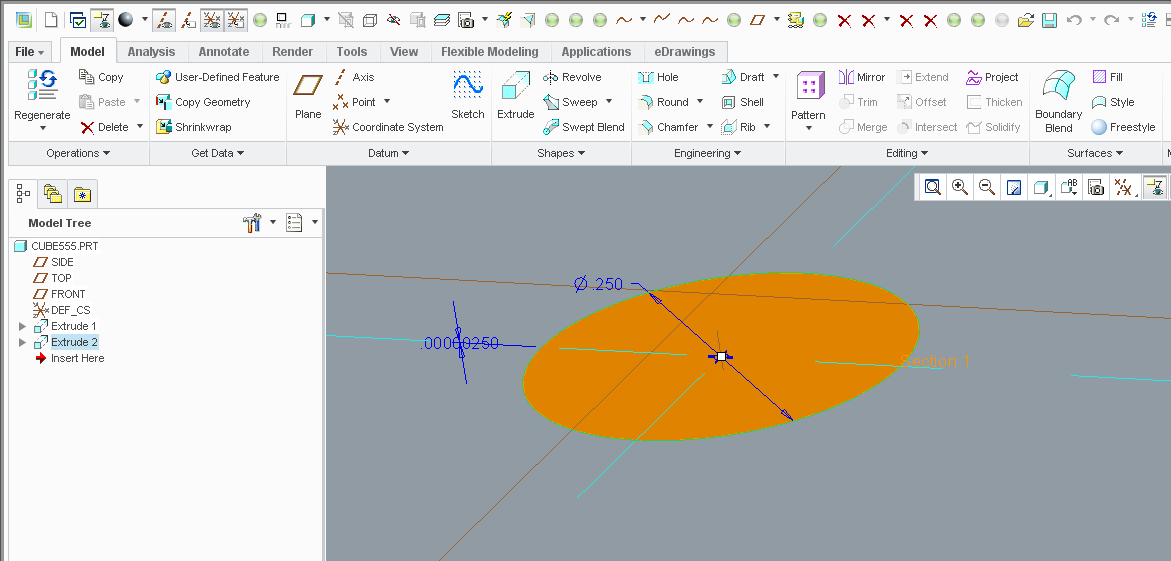

On a 5x5x5 cube, I can only project a feature no less than .0018".

I can revolve-cut a 3" disk on the cube's surface .001 deep. Once I change the cube to 6x6x6, the cut disappears without warning or errors. at 5x5x5, the cut disappears at .0005 deep. For me, these are real numbers.

All accuracy settings are set to .000001" in config.pro.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sorry... didn't see your reply before I typed that last one.

Let me try a 5x5x5 cube and see if I can reproduce this problem. I've never encountered one like this in the past that couldn't be fixed with an accuracy tweak. If this can't be resolved that way, I suspect some other kind of problem than may require PTC to investigate further.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I was able to make offsets of .0005 by setting the accuracy lower boundary smaller as I suggested. Setting accuracy to .0001 and assuming it will work because .0001 is less than .0005 is an error. The problem isn't absolute accuracy... it's the accuracy of a very small feature in relation to the much larger features elsewhere in your model.

Try setting your accuracy_lower_bound setting in config.pro to .000001 if you have to. If you set it fine enough, the feature will work. You may need an order of magnitude greater accuracy to create a super small feature in a larger part.

Thanks!

-Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Antonius...

Try this... whenever the system is trying to limit you, accept the lower limit. For example, accept .0018 for an extrude depth. Try changing it to a smaller value AFTER the feature has been completed and regenerated. This was an old trick... accept the default and then change it after regen.

I was able to make a 5 x 5 x 5 cube (in Wildfire 5) with the accuracy lower bound set to .000001. My feature depth is .00001 and it works perfectly. The image from Wildfire 5 is below.

I was able to open the same part in Creo Parametric 1.0 and set the hole depth even SHALLOWER. I set it to .0000025 as you can see below. Maybe this is an issue only with Creo 2? I don't have the ability to test in 2.0 at the moment. Is this what you're working in.

Thanks!

-Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In 2.0, it will not let you edit the feature to less than the minimum value during the extrude. It is utterly failing.

This is my config settings for the cube, which is native Creo 2.0.

sketcher_rel_accuracy 0.000005

default_abs_accuracy 0.000001

accuracy_lower_bound 0.000001

enable_absolute_accuracy yes

enable_assembly_accuracy yes

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ahh, ok try wipping the sketcher_rel _accuracy and default_abs_accuracy from your config.pro file and go with the system defaults.

I'll try this tommorow at work in Creo 2.0 F001.

I am almost sure Creo 2.0 is not an issue there.

Could you show what kind of shape are you trying to extrude or revolve? Do you use project edge function inside of sketcher prior to that?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There is precious little information on what these setting actually do.

But do remember that before I set these, I have the failures.

And once set, the failure mode hasn't changed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thats really odd. If your accuracy is set to absolute 0.0001 you should be able to extrude any not constrained sketch at least by 0.0002.

I was thinking you were projecting curves from your imported data. Is that right? I think the problem lies in your references which is as I see the imported data.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I agree Jakub...

Sounds like Antonius has found either a really insidious issue with Creo 2 or a problem created from the imported object. Maybe you need to re-import the part with the accuracy set very low?

Or maybe we're looking in the wrong place. Maybe this has more to do with the Co-Create import and the way it's being pulled in?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I discovered it in the import but confirmed it with native parts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Does it also prevent you from setting the dimension less than the minimum after the feature is created? Like... create it, hit the checkmark, get back to regular Creo, then try to modify it?

You'd think this is the type of problem someone would've caught upon validation testing.

Please keep us updated!

And good luck...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm downloading and installing M010 now.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, once I've returned from the creation dialog, and try "edit" on the fearure, it will not let me put in any value lower than the error value during creation.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I suspect that the concentric circles pulled from the imported data aren't really circles.

But I am also not really sure why should that be a problem there.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The imported .pkg files are quite reliable.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Arrggggg!!!

M010 didn't fix this issue... but is deleted everything else stored in F001!

I'm pretty much hosed now.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've done more testing and I am really getting concerned.

No word back from tech support; the update to M010 did nothing but lost a weeks worth of configuring.

This example is a 19" rack panel (19" x 5.25" x .125") with a thin strip on top.

The minimum thickness I canmake the strip has to be over .004" As I increased the size of the panel, the thickness required kept increasing. Errors aboud if you start changing your part size. This is absolutely insane!

Make a note of the error message in the regen error:

This feature is defined with dimensions that are very small compared to the rest

Who is PTC to decide on what I want for a feature size? I -WANT- .002 thick silkscreen on my panel!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Damn... have you ever seen the "Part Setup Menu" in Creo? I haven't either.

Answer: FILE/PREPARE/MODEL PROPERTIES/Materials/Accuracy and "change" this to Absolute and give it an appropriate value.

So config.pro may set the values, but doesn't activate the Absolute Accuracy toggle. It was -still- stuck at Relative regardless of the config.pro settings.

If you don't see this switch in the Model Properties menu, you might have to set enable_absolute_accuracy to yes in config.pro.

Seriously... I can see why PTC enabled relative accuracy... but to make it default? Argggg!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Oh right, I forgot that the model properties menu is so much harder to find in Creo Parametric than in Pro/E.

Should have mentioned it in my first post.

Anyway well done on finding out the solution.