Community Tip - New to the community? Learn how to post a question and get help from PTC and industry experts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- how do i make a hole angled at 8.5 degrees to a su...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

how do i make a hole angled at 8.5 degrees to a surface

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

how do i make a hole angled at 8.5 degrees to a surface

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

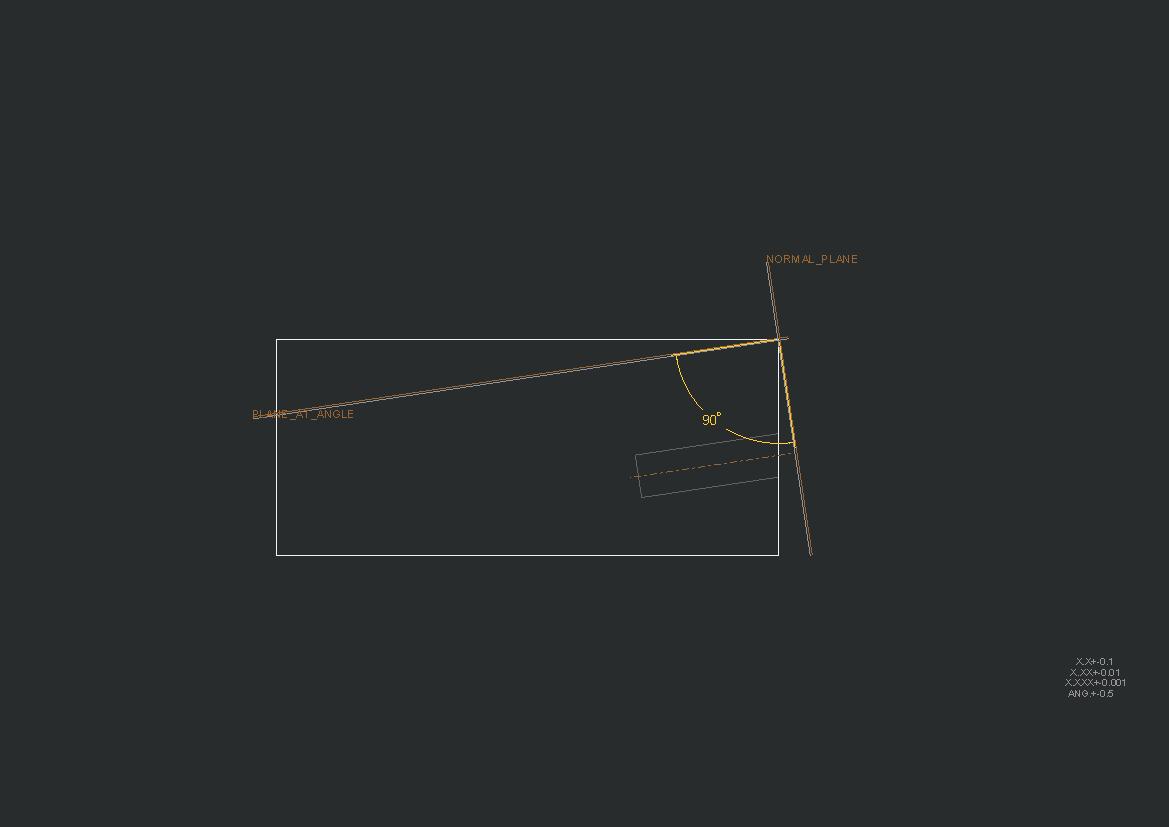

i have attached the image..i think it is self explanatory..i have used the hole option to create the hole

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Welcome to the forum, Rohit Rajan.

A hole in Creo is simply a revolve cut. Often times I find a sketch much more powerful when making a hole at an angle. It allows me to add relative references to echo on (show/unerase/whatever) in drawings.

Using perpendicular planes work fine in general but it can have unexpected effects when that plane is not tied closely to the function of the hole.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonious, A hole is not just a revolved cut. A hole feature has much more power as you can define counterbore's, coutersinks, threads, and many other easy changes in a hole that you would have to model manually. Also multiple holes can automate the assembly of mating screws in an assembly.

Please take another look at the hole feature and the additional power it provides.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I didn't mean to minimize the usefulness of hole features and the improvements made over time... all I was saying is that for non-conventional holes, the revolve is the primary function of a hole feature... secondary is the ability to add a cosmetic thread in the same command, and finally, it can be tied to hole tables that will help a company standardize their hole features. And yes, as you can pattern a hole, you can pattern a revolve. Either way, it would have the sense to pattern hardware in assemblies.

I will certainly use the hole feature on many occasions when the hole is planer to the surface, but I also use the revolve -a lot- when making slight skewed holes or making holes on curved surfaces. I can then apply all the relevant references I need to use on drawings, which usually means dimensions to the axis center point where the hole meets the surface, and the follow-on references about the hole from this point. Knowing what Creo does behind the scene makes using revolve to come up with the same feature a lot easier.

I also find the hole tables extremely unfriendly when you have a lot of different clients. Each want to specify a hole in a slightly different way. Personally, I don't have a problem with formatting a note for thread and hole callouts. It takes way to much effort to tweak the hole tables for every whim of a particular customer.