Community Tip - When posting, your subject should be specific and summarize your question. Here are some additional tips on asking a great question. X

- Community

- Creo+ and Creo Parametric

- Manufacturing (CAM)

- Re: Machine play going from opposite sides (Exampl...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Machine play going from opposite sides (Example B0 to B180) will not rotate.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Machine play going from opposite sides (Example B0 to B180) will not rotate.

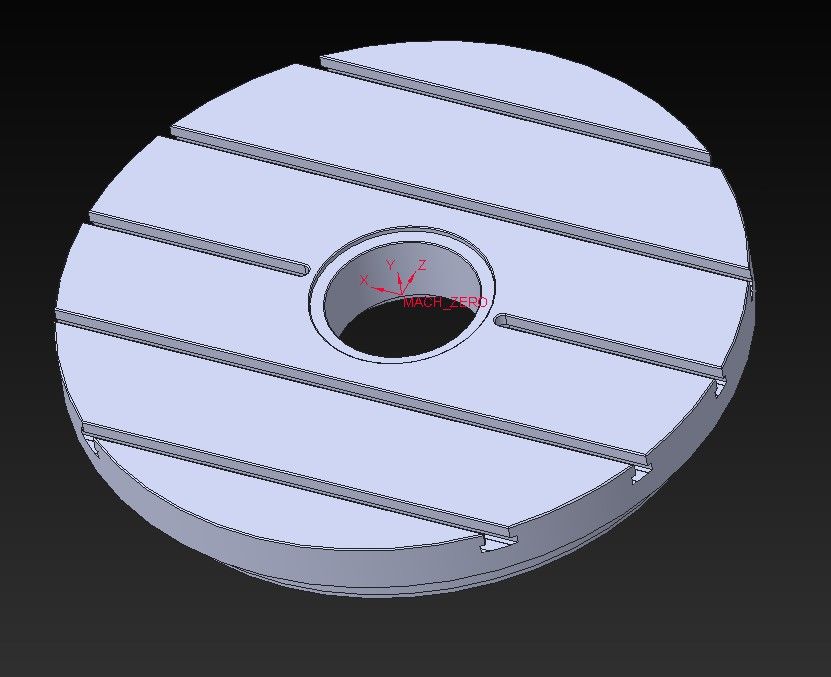

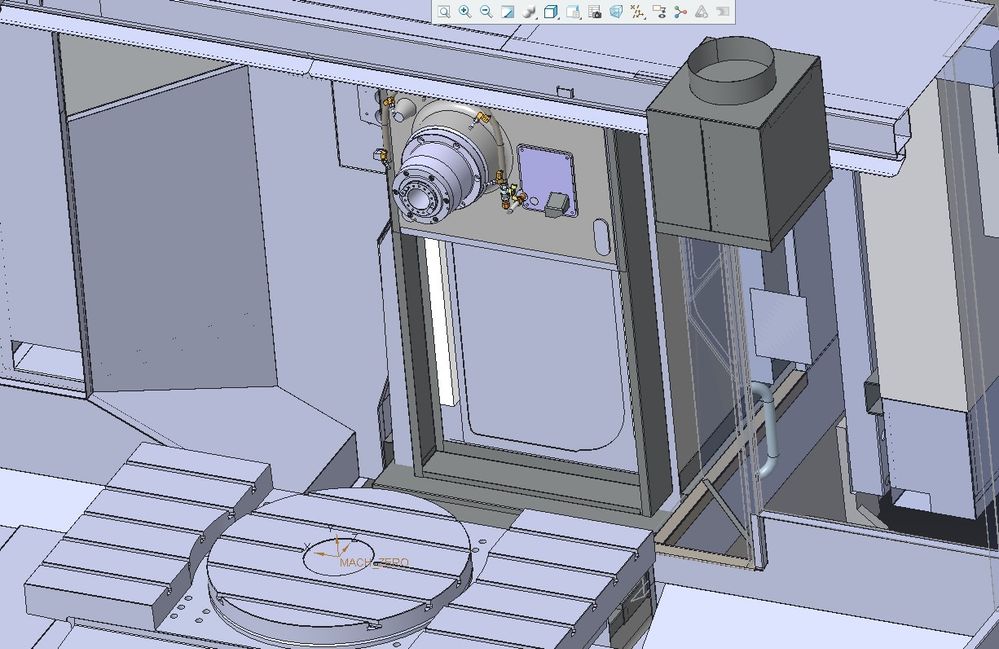

I have a working kinematic model that will work fine as long as you do not immediately rotate to the opposing side. If I start machining on B0 and go to B180, the Z travels right through the part and continues machining without rotating the B axis. But if I go from B0 to B90 and then on to B180, it will rotate as intended. If I go from B90 to B270, it also will go straight through the part. My "MACH_ZERO" CSYS match each other, I can't think of anything I have done wrong on my end. Any ideas? Or is this just another thing that Creo offers but is broken?

Also, if I start on B180 as my first machining side, then with all following rotations, the tool will go through the part. I put together the following demonstrations.

Solved! Go to Solution.

- Labels:

-

General

- Tags:

- machine play

- opposite

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

HI

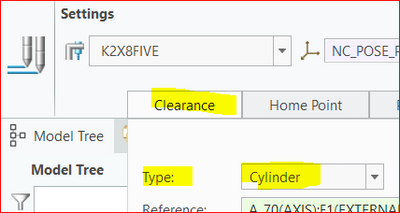

try to take "cylinder" as a type of clearance

Abdel

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the suggestion, and that probably is the correct answer. However, when we set that to cylinder, it does not code out correctly. As far as I know, this is a known issue at Austin NC the last I talked to them.