Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Creo Challenge for fun 2017

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creo Challenge for fun 2017

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo Challenge for fun 2017

Good day everyone,

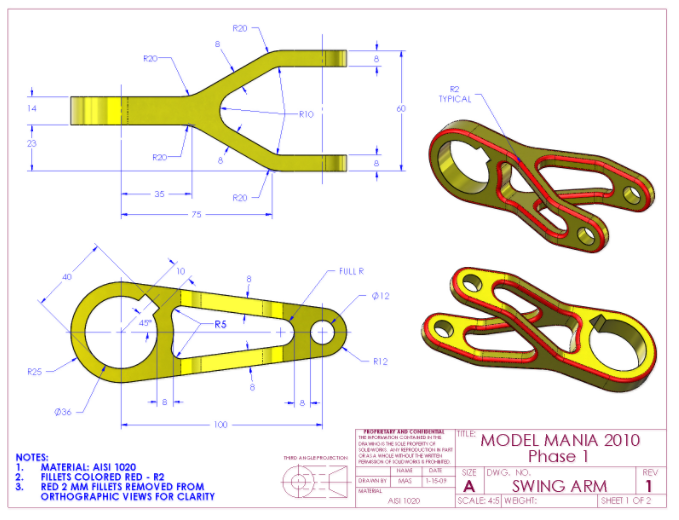

Attached is the drawing from the LiveWorx 17 Creo Battle Royale.

During LiveWorx, contestants were given a combined score based upon time to complete (up to 20 min) and a score for the quality of the model.

Certainly, it will be difficult to judge time, but for fun, please post your drawings - we are looking for accuracy.

Do you have the chops?

Post your solutions here Creo Challenge for fun 2017 - PTC Community

Best,

Toby

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

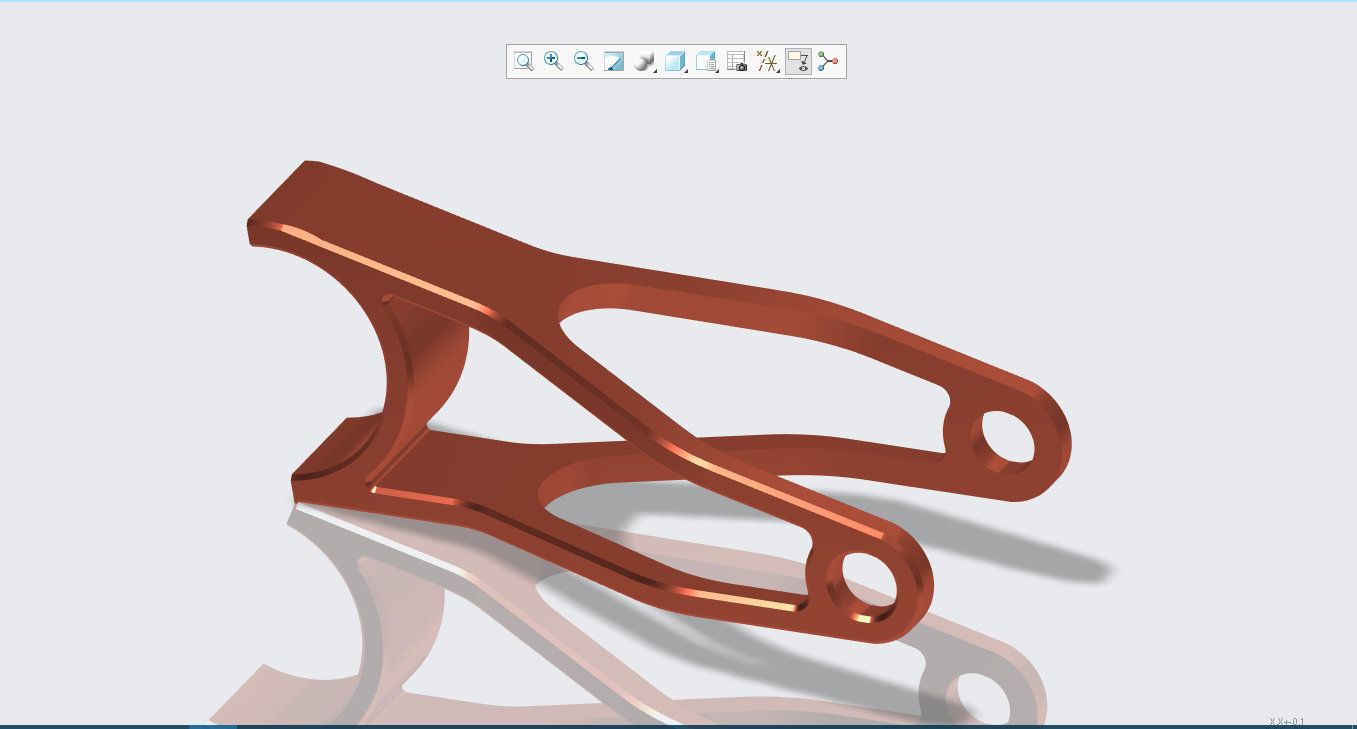

The gold color and mirror is a great touch Steven!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Very nice Steven.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You are right. I used the intent edges that selected all the edges to round.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Done !!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

These are excellent everyone! Please keep them coming.

Best,

Toby

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Toby,

Can you post PDFs of prior year drawings from the challenge?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the request Ben Loosli

Here is a link to last year's challenge, I am sorry that I do not have the original PDF

Best,

Toby

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How many features did everyone use??? I got 4 but could have gone down to 3... Anyone get less than 3? Took about 10-15 minutes.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

From my point of view, we should not look at the number of features. In general features need to be as simple as possible for faster regeneration and for future modifications.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've worked on models where every possible contribution in topology was a separate feature. They'd make that part with 30 features or more. Ever look at 50 separate rounds randomly sprinkled in a model tree? All need to be the same radius, but now that radius needs to change.

On a side note, years ago I asked for software execution profiling - time and memory statistics on a per-feature basis so that complexity vs simplicity could be compared and was told PTC always worked to produce the optimum result. Which is great, but users don't do optimum things. Does a sketch with 50 topology contributors take longer than 20 sketches with 60 contributors, the 10 extra ones just there to cap the incomplete boundaries left from subdividing the original? Is it better to see a coherent sketch or a model built of 90% scaffolding datum planes and sketches and curves?

Too often I've been burned by vast chains of useless dependencies carried through a big pile of simple sketches. Delete one hole and halfway across a part a chamfer disappears, taking a bunch of rounds with it and another hole.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm with dschenken on this one, but I see the merit in your point of view Manjunath. My question was simply out of curiosity since I can't see a way this Challenge part can be made with any less than 3 features. I'm sure someone could build a feature tree 100 features long to get this simple part, and the case can easily be made to use more than 3 for design flexibility reasons.

I personally try to group features as best I can using common sense and as much forethought as I can muster. Dschenken, I actually HAVE had to work with another engineer's model that had 10+ individual round features of the same size, and would always remain of equal size. I'm a firm believer in naming features in a relative way, "Base extrude, Mounting Bolt Pattern, Support gusset, etc" to help simplify, organize and make sense of the model tree. It's easy to start from scratch on a model and go thru the whole design then look back and try to remember which of those extrude features was the extrude cut you're now looking to tweak. When it comes to obscure dependencies, I've been so frustrated at times that I nearly throw the computer out a window. Adjust the round radius by 0.010" and the whole part grows by 60"... ![]() Dependencies are incredible tools when used in the right context and with the correct setup, they can be absolutely counterproductive when abused.

Dependencies are incredible tools when used in the right context and with the correct setup, they can be absolutely counterproductive when abused.

Good discussion folks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

![]()

I absolutely agree with you Dschenken.

By making features simple, I meant not creating many number of rounds of same value.

Instead, not complicating the feature sketches until the sketcher starts to flicker, for which that complex geometry can me made by splitting into simpler multiple features, also keeping in mind the references that these small features will have further down the model tree.

So in general, a model having more number of features is not a bad model, or vise versa. it all depends on how easy is it to modify for others using that model; as rightly said by Mitch, should not be a frustration for others.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

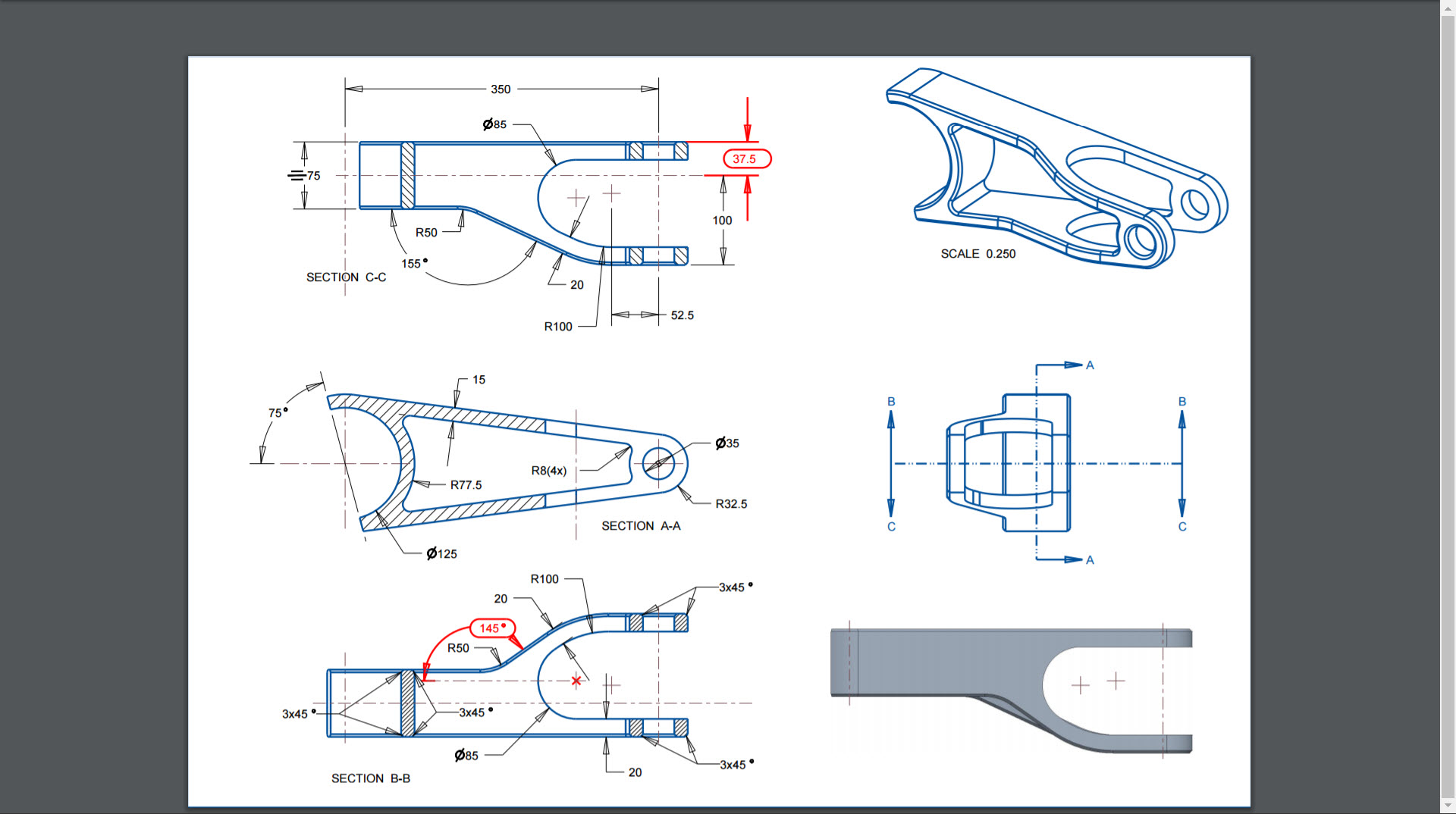

Continuing the feature count discussion, when I built this at the show I was torn on whether everything in this view should be sketched together or if the inside area (along the red lines) should be done as a separate feature.

Based on the way it's dimensioned, if you really want these dimensions to be the "real" controlling (think shown) dimensions, you are forced to sketch both the inside and the outside at the same time. If instead of the R100 the designer had called out R120 on the outside of the part, the inside area could have been created completely separate from the outside.

These type of modeling decisions can definitely impact how easy the model can be changed in the future. I know that for the final championship round they were going to give each of the finalist their original models back and then require them to make certain changes. I didn't get a chance to see it but maybe Toby Metcalf can get a copy of that final print too. It would be interesting to see if any of the initial modeling decisions end up causing trouble later.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I will see what I can find Tom.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

For me, Design Intent is most important. Capturing the right Design Intent will result in fewer and more stable features.

I create the "generic models" which our engineers use for their projects. Using the right references is critical for our models to behave stable. A change in our design (using Excel to drive 1250+ input parameters) can result in 20k features to be regenerated. I don't want our engineers to face even a single resolve dialog.

For some parts, I can delete/suppress the very first feature (extrude) without all the other features failing. Every other feature is sketched/constrained to datumplanes.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting. Thanks for finding this. Knowing this, does it change the approach anyone would have taken on the initial model?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How's this for a concept - the output has to be a drawing of the part, all dimensioned like the original. Then step 2 is to add key-lock inserts. See who planned ahead and made an assembly model when given a part drawing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sounds like you need to join the multi-body (Focus Group for Embedded Component Use Cases in Creo) working group! There were lots of discussions in Boston last month on the best way to handle this very concept.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's a 20+ year old problem. I would be surprised if many use-cases and solutions haven't been kicked around inside PTC development for a long time. The problem is significantly complicated by dealing with any PDM system.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't get it...

Dimensions on a part should go on the drawing of a part.

If later those key-lock inserts need to be added, then you create an assembly, insert the first part and place/constrain the key-lock inserts. The drawing of the assembly only shows the dimensions regarding the position of the key-lock inserts...NOT any dimensions of the part (which are all at the drawing of the part).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Key-lock insert installation is considered an inseparable assembly, which is detailed as a part. Same thing with weld-studs, PEM nuts, and others.

Not everyone treats them this way, but plenty of users do.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I agree that the resulting assembly will be inseparable, but I will have to disagree for the need to detail that as a single part/component.

In our case, person A can make the main component and person B can buy/purchase the key lock inserts. Then, person C receives all the components and assembles them.

Person A needs to have the drawing of the main component, nothing else. Person C only needs to know where those inserts need to be place (location, depth, etc.), but he does not need to know how to produce/manufacture the main component.

That being said, at my previous job I did use the "single-part assembly" method, but that was for sheetmetal (but I can't remember exactly WHY)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Many companies want to buy those sheetmetal parts complete with the PEMs or riv-nuts, etc installed. They consider it an added expense to produce the "extra" drawings, track the multiple part numbers and/or setup operations to add the components in house after receiving the sheetmetal part.

From an creo standpoint, it used to be significantly difficult to replace a part with an assembly. Interchange assembly was your only real option if you had any parent child relationships to speak of. It's easier now but depending on how you build your models, it can be a mess.

It's really a company-by-company decision. We tend to want our software to be flexible enough to help us do our job and not make impossible to adjust to situations and changes as they come up.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

My proposal for the Creo 4 view replace model project included replacing a view of a solid with a view of an assembly with the solid as an immediate component. But as it went, that's on the 'for the future' list.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Inseparable assembly or separable assembly, the file is still an assembly. Even with Unigraphics, which allowed multiple solid bodies in a single file, we used the assembly approach for the addition of PEM fasteners, weld studs, etc.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Solidworks Model Mania Challenge from 2010. the Original and Revised drawings of the 2017 Battle Royale look eerily similar to the Phase 1 and Phase 2 models from the 2010 challenge in SW.