Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- How to Control Rounding dimensions (roundig Up and...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to Control Rounding dimensions (roundig Up and Rounding Down)?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to Control Rounding dimensions (roundig Up and Rounding Down)?

Hello,

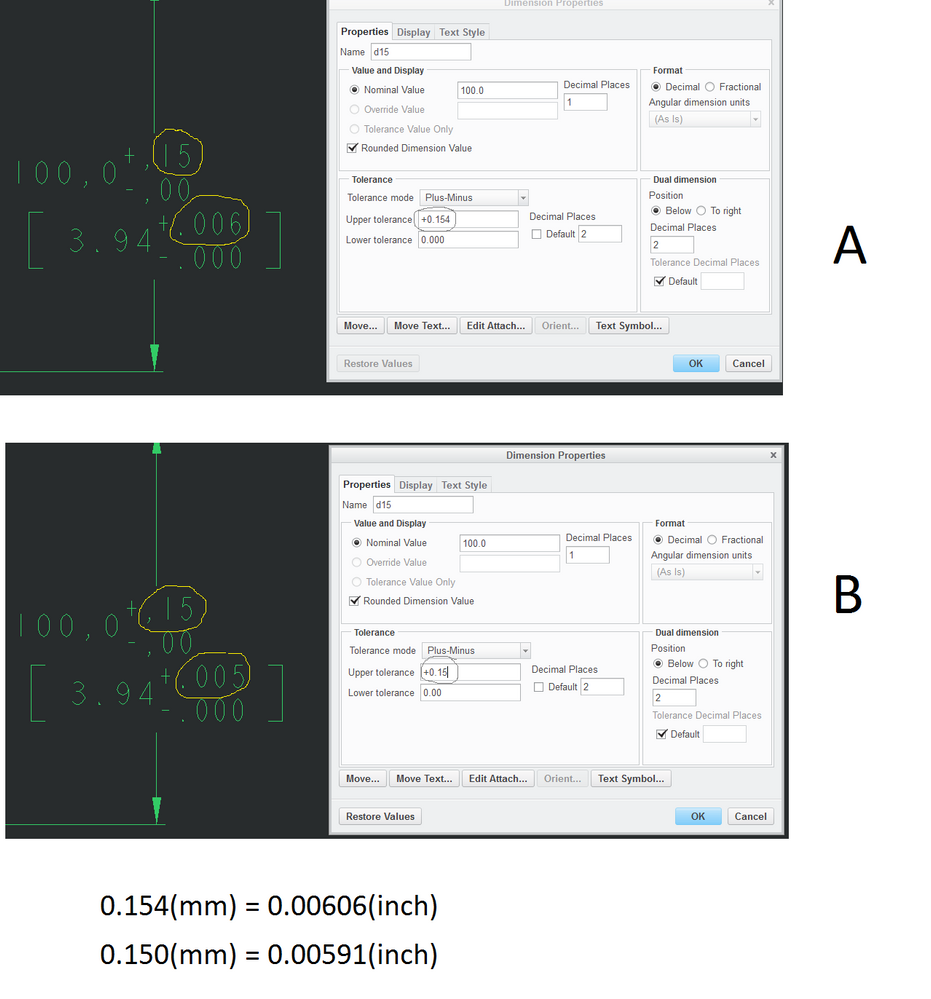

Can anyone know how to control decimal rounding up/down value in Creo drawing?

Please see the screenshot of it

I want to give a tolerance of 0.15, not 0.154.

but in inches, it should be 0.006.

here the tolerances are rounding down. I need them to round up.

Regards,

Sundar Dannana,

Engineer.

Sundar Dannana

Mechanical Engineer,

ExtruDesign.com.

Solved! Go to Solution.

- Labels:

-

Sheet Metal Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

...and the bottom line being that the bracketed dimension must always lie within the tolerance band of the primary displayed dimension. This is according to ASME ...whatever it was. So yes, you can loose tolerance within the bracketed dimension. In general, this is a good solution.

This standard enforces the importance of which is primary and which is secondary. All too many times have I seen suppliers try to take advantage of this by doing their own translation of the numbers when dual dimensions are not present. I do remind those suppliers that the numbers on the drawings is what I contracted, not a conversion of those numbers to a different system improperly implemented. in this case, you should be able to trust what PTC has done in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There was a lengthy discussion of this stuff previously here. A quick search of "creo dual dimension rounding" brought me to the following:

It starts with a question about standards and branches off to a lot of links about what I think you are trying to address.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

...and the bottom line being that the bracketed dimension must always lie within the tolerance band of the primary displayed dimension. This is according to ASME ...whatever it was. So yes, you can loose tolerance within the bracketed dimension. In general, this is a good solution.

This standard enforces the importance of which is primary and which is secondary. All too many times have I seen suppliers try to take advantage of this by doing their own translation of the numbers when dual dimensions are not present. I do remind those suppliers that the numbers on the drawings is what I contracted, not a conversion of those numbers to a different system improperly implemented. in this case, you should be able to trust what PTC has done in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

...and also know that I have no love for bean counters who cannot understand why you may want to use one for the primary value over the other. A company that restricts engineers into one corporate dimensioning standard is only doing it t make their jobs easier. There has to be allowances in certain cases. In precision machining, those lost few microns or nanometers can cost real money. I trust myself to know what I need to use and why. And I've had to deal with plenty of the bean counters in my 40 year career. Most of which are stiff-necked people that simply do not want to understand.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It would be easier to 'trust' PTC if they applied proper standards to their techniques. Rounding of dimensions is BY STANDARD to the even number when the last digit beyond your significant digits is a 5. Without following the standard, you get some rounded up and some rounded down and no consistency!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That rounding rule was created by statisticians. Based only on proximity to the nearest rounded value, a trailing 1,2,3,4 causes the value to go down and a trailing 5,6,7,8,9 causes the value to go up; a ratio of four roundings down to five roundings up, which causes large numbers of roundings to shift the results upward.The reason for the asymmetry is that rounding a trailing zero causes no change in the value.

To fix this problem statisticians decided that since even and odd values are assumed to be random, shifting the effect of the 5 based on even/odd result makes it average out to 4.5 roundings down to 4.5 roundings up, for large numbers of roundings.

When it comes to double dimensioning the secondary dimensions should be entirely within the primary range regardless of the numerical error introduced by the unit conversion and this means ignoring any statistical rounding rules that would allow values to be outside that range.

In this case, I think it was a huge mistake for PTC to allow rounding of dimensions.

As a general FYI

.154 mm = 0.00606299212598425197 inches, approximately and

100mm = 3.937 exactly, not 3.94, so the original conversions are off.

If the goal is to make the range from

100mm to 100.15mm,

the OP desired inch conversion results in a range from

100.076 mm to 100.2284mm (3.94 + .006),

adding significantly (.0784mm) to the tolerance range.

The PTC conversion range result is 100.076 to 100.203 (3.94+.005) , which is still bad, but not as bad.

Had the secondary dimensions been 3 places instead of 2 then .005 tolerance would result in losing .0232mm of dimension range on the top end and using .006 would accept parts .0022mm outside the primary range.