Community Tip - When posting, your subject should be specific and summarize your question. Here are some additional tips on asking a great question. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Shell problem

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Shell problem

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Shell problem

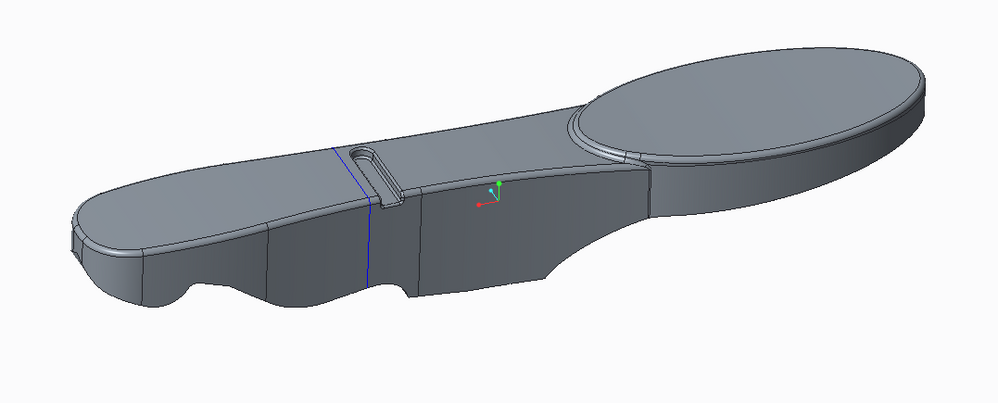

Hi there, I am new to creo and trying to modell some things for practice.( i am used to solidworks) I am currently modelling a washcloth. But i encounter a problem I want to shell on both sides. But in order to do so i need a split line on the place the curve is added. I added some images to explain. Thank you in advance.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You aren't going to be able to easily use the shell feature for this. This is a case where multibody modeling like SW has can be handy, you can build two different solids, shell each and then merge them. Not possible in Creo, however.

The only way is to build one "half", shell it and then add the other and try to shell it. However, Creo is going to want to try to extend the second shell into the rest of the part. It's likely to fail, unfortunately.

You may need to use offset surfaces and a solidify feature to create the second "shell". You'll make a copy of the outside surfaces, offset that quilt and then solidify it as a cut.

You can also try shelling all from the one side, then use regular features to remove the other surface adn fill in the opposite side.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Shell is a very useful feature but you find that you want to use it earlier in the process that you would prefer.

I find it useful to consider modeling parts such as this in surface/quilt geometry and follow up with a thicken feature.

I would add the smaller features and details after that if the thicken feature is a greater thickness than the detail feature.

These types of exercises are wonderful in learning the tool. Kudos to you for taking on this challenge.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's indeed not trivial to apply shell on certain part of the geometry, given Shell auto - applies to all solid geometry.

This actually gives you a clue how to reach this : at a moment of Shell only necessary part of the solid need to be "in solid shape". As mentioned this is not trivial, but definitely possible with some quilts work.

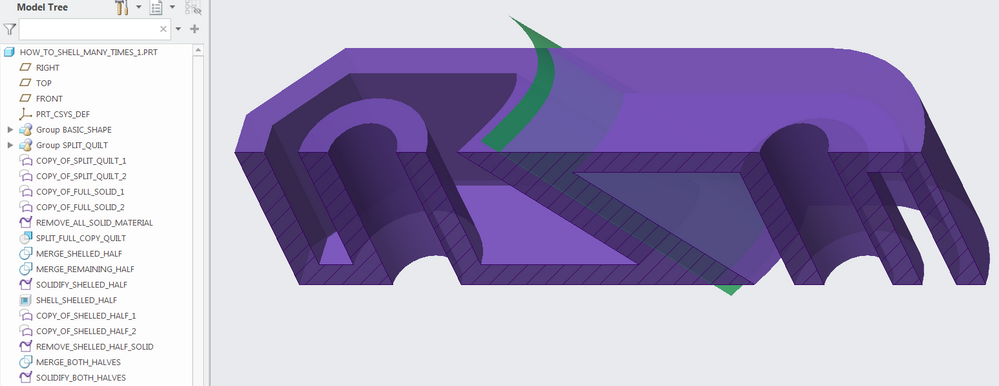

Example attached,

1. have bunch of basic solid features

2. Prepare Split quilt

3. Copy this quilts twice (Split Quilt 1 and Split Quilt 2)

4. prepare 2 copies of "all solid surfaces" (Solid Surfs 1 & Solid Surfs 2)

5. Remove all solid geometry by Solidify of Solid Surfs 1

6. Trim quilt of Solid Surfs 2 by Split quilt, keep Both Sides

7. Merge left side quilt with Split Quilt 1 and right side quilt with Split Quilt 2. At this time we have 2 halves with closed quilts.

8. Solidify left half and Shell it per needed.

9. Prepare Copy Solid Surfaces of Shelled Left Half twice (Solid Surfaces of Shelled Left Half 1 & Solid Surfaces of Shelled Left Half 2)

10. "Solidify" Solid Surfaces of Shelled Left Half 1 as a remove material. Again we have no solid in the model.

11. Merge quilts "right side" and "left side shelled"

12. Solidify the result. It's all done.

13. Make UDF from it and enjoy it for any further "partial shell" needs - it does work quite reliable.

Regards

- Vlad

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator