Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Welding across welds.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Welding across welds.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Welding across welds.

Hi All

My first post!

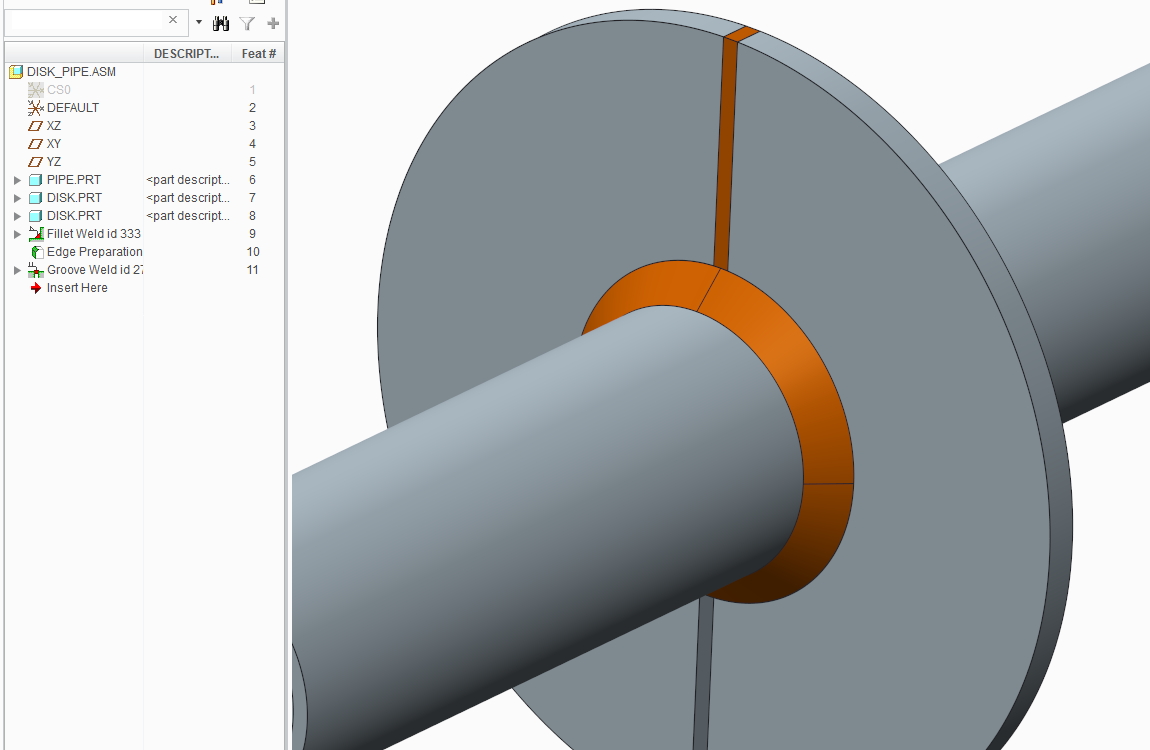

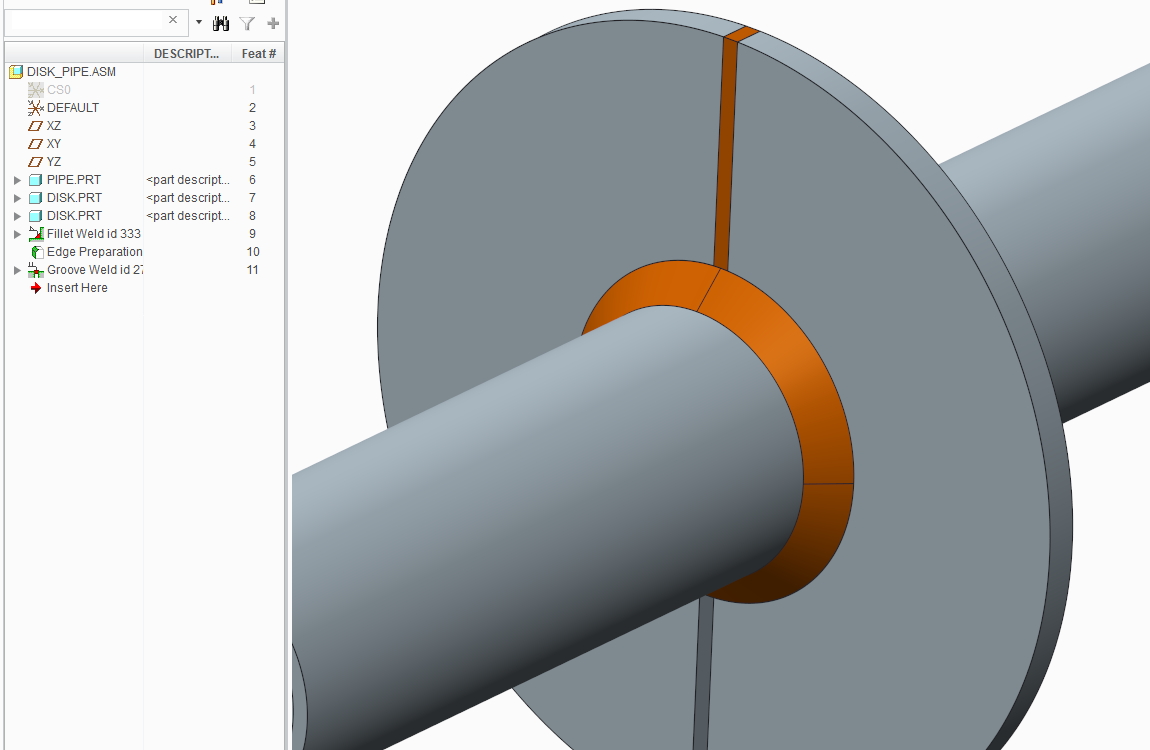

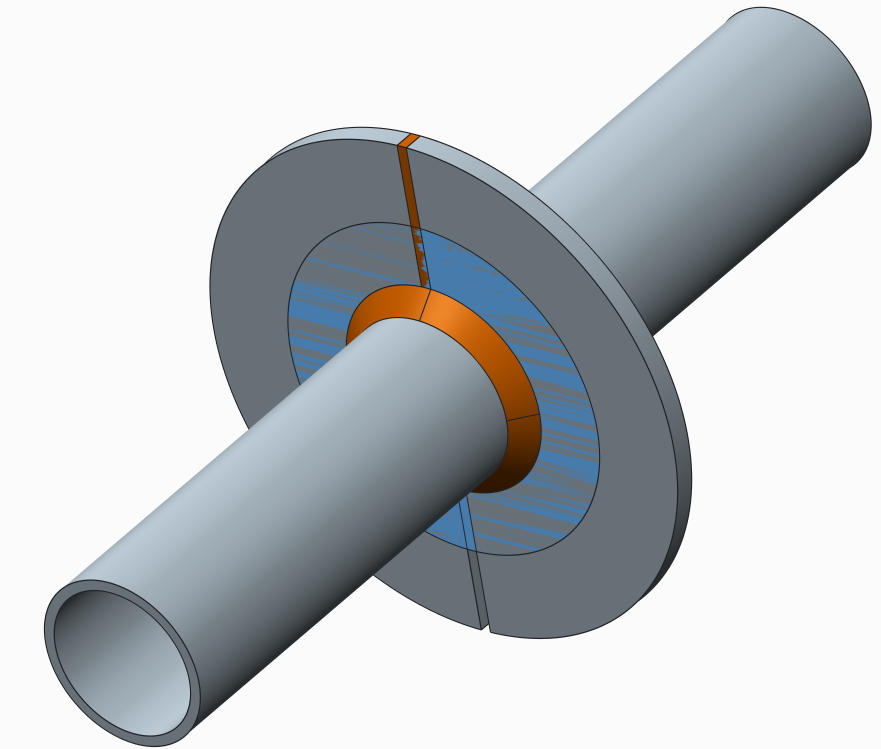

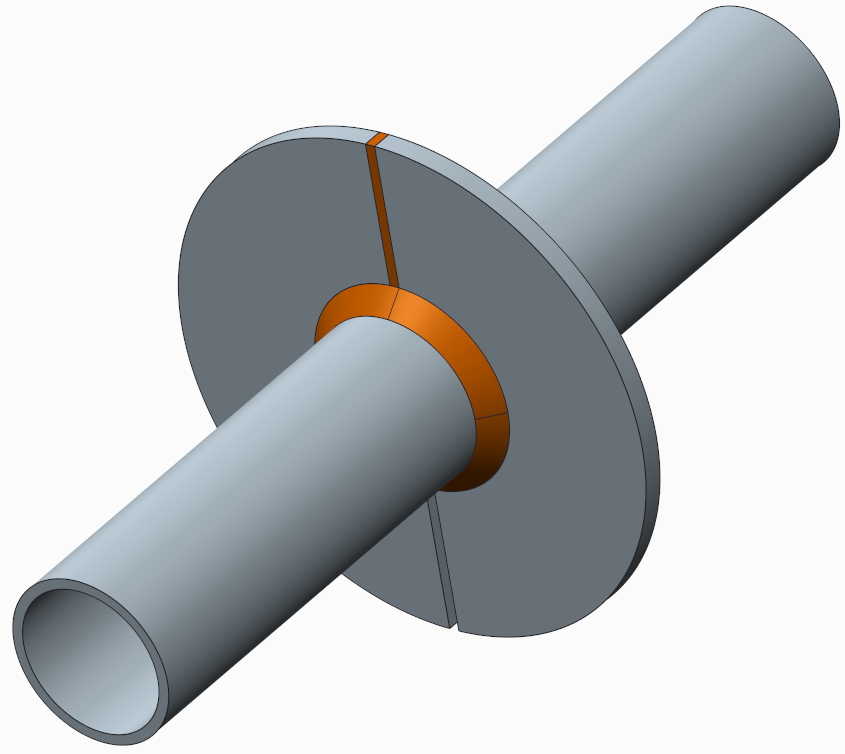

Attached picture shows my problem. I am welding two semi-circular plates to a tube.

I first weld the two plates together then weld the plates to the tube but the weld is split across the plate weld. I've tried everyhting I can to correct this without success.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

Weld Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

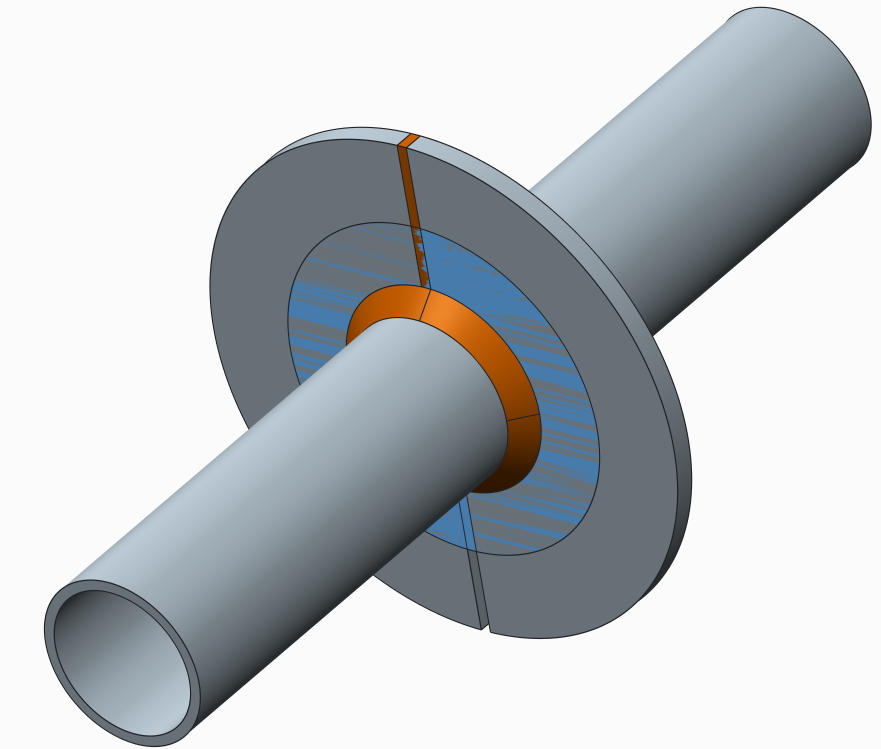

The gap exists because there is a gap between the two surfaces as you would expect for a groove weld. For the secondary weld, it follows the surfaces of the original geometry with the gap in it.

I can think of two ways to fix it:

1. Don't create the edge/weld prep as feature in the model, do it as a weld prep feature in the welding application. Move/create your fillet weld prior to the edge prep in the model tree.

2. You could create a surface that represents the face of the two welded disks and then reference it for the fillet weld between the welded plate and the tube. Then just hide surfaces in the layer menu and save the layer status.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The gap exists because there is a gap between the two surfaces as you would expect for a groove weld. For the secondary weld, it follows the surfaces of the original geometry with the gap in it.

I can think of two ways to fix it:

1. Don't create the edge/weld prep as feature in the model, do it as a weld prep feature in the welding application. Move/create your fillet weld prior to the edge prep in the model tree.

2. You could create a surface that represents the face of the two welded disks and then reference it for the fillet weld between the welded plate and the tube. Then just hide surfaces in the layer menu and save the layer status.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

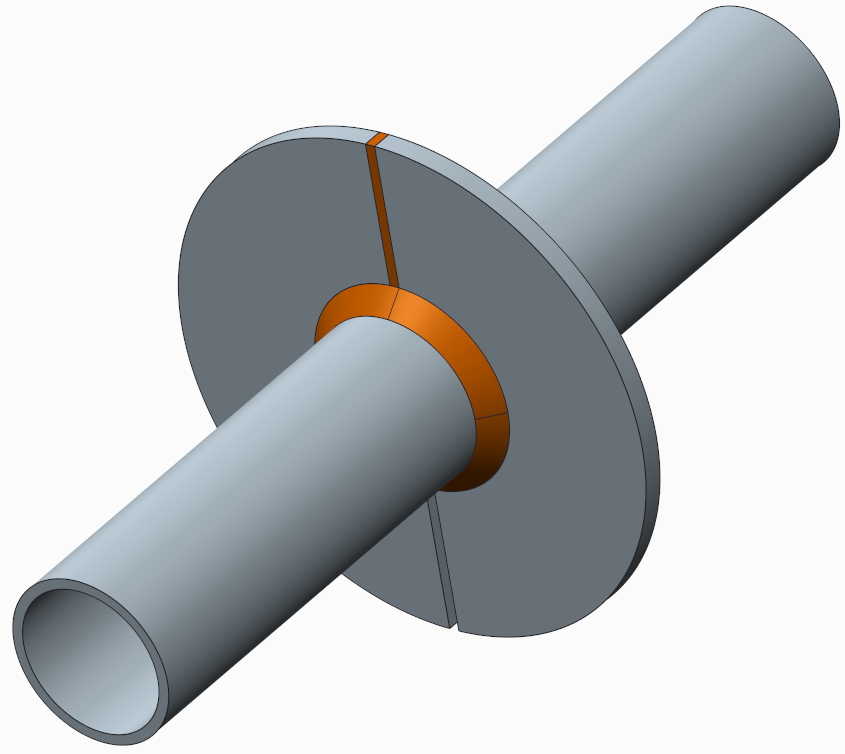

Thanks for that, works a treat!

Took me a while to get the surface to look tidy, after I put the weld on the drawing showed a ring so I created a new layer and hid that.