Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Load of an overhead crane

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Load of an overhead crane

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Load of an overhead crane

Hello,

I would like to try to simulate the load of an overhead crane on the lower wing of a beam, for example of the HEB type.

I can't highlight the bending of the wings and its constraints.

Has anyone ever experienced this problem?

I'm still on Creo 3.0.

Sincerely.

Denis

- Labels:

-

Simulate

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

do you have cad-data?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

Thank you for your interest.

I don't have a CAD drawing.

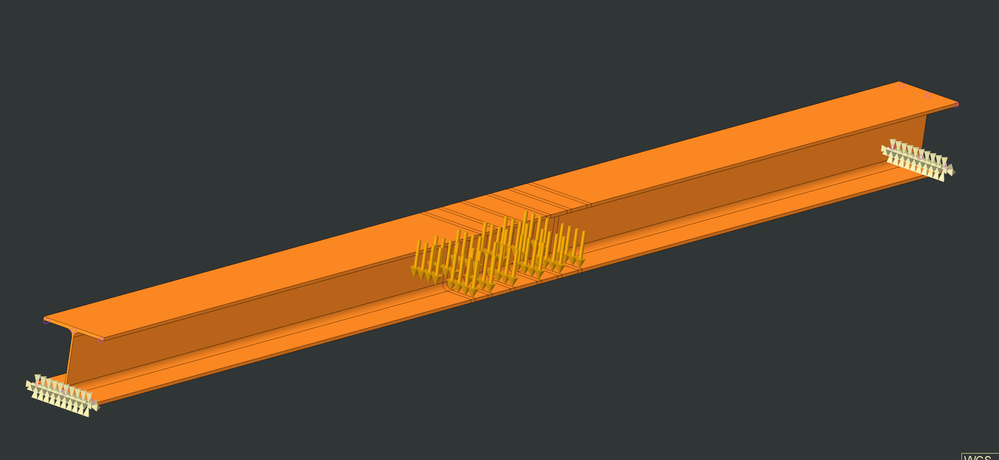

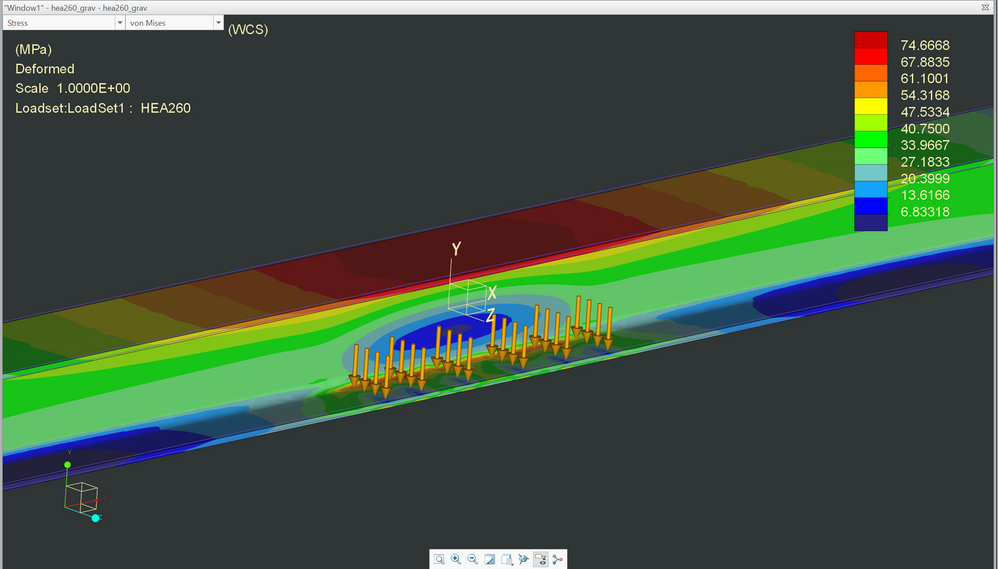

But one can imagine a HEA 260 truss with a point load of 3000[N] on the lower wing on either side to avoid a torsional effect.

Sincerely.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

Thank you for that quick and complete answer.

What I don't understand is this constraint delineated at the front of the truss.

It stops exactly at the support of the load.

Sincerely.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

it's a example only...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for this first approach.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

To help avoid confusion, in English "Contrainte von mises" is "Stress von mises".

so "What I don't understand is this stress delineated at the front of the truss."

Constraint is something very different.... the restraint at the end... Hold X,Y,Z...

The reason for the stress vm stop/discontinuous at the load is best shown by two things.

1. Shear diagram for simply supported beam.

2. General von mises equation. The coefficient is 6 on the shear terms so they dominate. (That is why the tresca diagram is similar to the von-mises.)

plot stress XX and you will find bending stress for this beam.

plot stress XY and you will see shear stress for this beam.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for your answer, your comments and the links.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

your welcome,

Some more comments.

I tried this beam in 5M length, simply supported.

The beam as a member appears strong enough for 60kN with about a 7 times safety factor, with one caveat, the local stress where the load is applied. The load cannot be a point load, it needs to be spread out evenly over a large enough area to reduce local stress enough to make the system efficient. That is why overhead cranes have many rollers that spread the load out. Keep in mind that stress is force/area (F/A) and a point load has 0 area. F / 0 is undefined. This is why @skunks used a rigid link at the load. I applied the load to surfaces representing the contact with the rollers. Let us say you allow 30MPa stress. From that and F/A you can calculate the minimum area of contact. For example 60kN / 2000 mm^2 = 30 MPa. Thus we need at least 2000 mm^2 of roller contact area to start with. To avoid other local bending of the beam flange, much more area and a spreading out is needed. Even with this much larger area (>30000 mm^2) I still have 70MPa. Maybe my next step is to upgrade the beam, or maybe even using IPN standard beam instead of HEA. (Or S-Section "American Standard Beam")

I have interest in this because someday I hope my garage will have a beam trolley. 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for these details.

I attach a link to you where you will find documents on the calculation of overhead cranes, but it is in French.

https://www.sendspace.com/file/66xe4l

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator