Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Managing thickness of an igs file

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Managing thickness of an igs file

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Managing thickness of an igs file

Hello everyone, i've been working on this file(s) for a quite some time now as part of my thesis. So far im stuck and asking here seems like my final solution, don't know what else to do really.

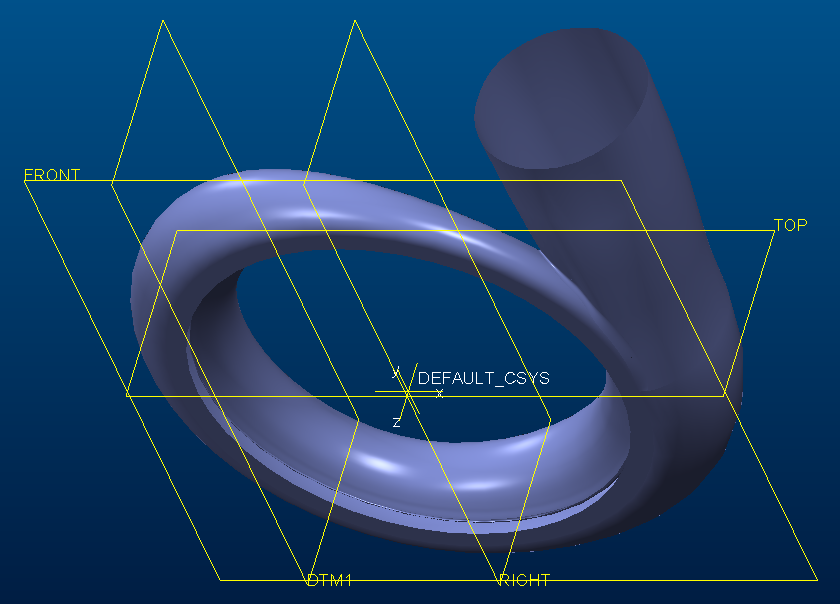

The goal here is to have 2mm of thickness on the whole part. and of course it is not possible to simply use the shell command. I've found a solution with "2 sketches + fill + merge + solidify + extrude" method but i just simply can't get 2mm thickness (or any other thickness). I will add some pictures for you to see what I've tried to do exactly.

The second version of this part (name starts with "Testcase") has no thickness, seems actually pretty easy with thicken command but like the first igs file, there are so many gaps on the part and i just can't make it "closed" completely. The second version also needed scaling but that was not a problem (scaling 180/700 is okay).

So I've hit a big brick wall here with this task. I hope someone can help me with it.

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can't open your file, but you may have an accuracy issue.

Go to File - Prepare- model properties - Accuracy change

Try making the accuracy number smaller

If it's set to relative, try setting to absolute.

Make sure you have saved prior to making these changes. Sometimes accuracy changes will cause unexpected failures.

This post has good info on accuracy: https://community.ptc.com/t5/Manufacturing/Absolute-vs-Relative-Part-Accuracy/m-p/267380

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@mmelenli wrote:

Hello everyone, i've been working on this file(s) for a quite some time now as part of my thesis. So far im stuck and asking here seems like my final solution, don't know what else to do really.

The goal here is to have 2mm of thickness on the whole part. and of course it is not possible to simply use the shell command. I've found a solution with "2 sketches + fill + merge + solidify + extrude" method but i just simply can't get 2mm thickness (or any other thickness). I will add some pictures for you to see what I've tried to do exactly.

The second version of this part (name starts with "Testcase") has no thickness, seems actually pretty easy with thicken command but like the first igs file, there are so many gaps on the part and i just can't make it "closed" completely. The second version also needed scaling but that was not a problem (scaling 180/700 is okay).

So I've hit a big brick wall here with this task. I hope someone can help me with it.

Hi,

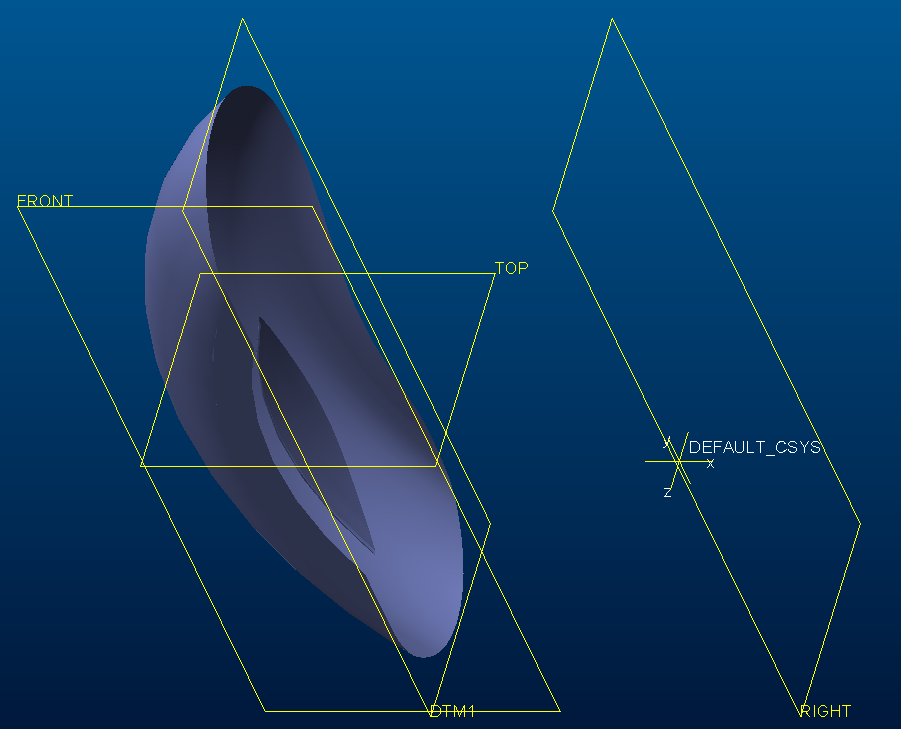

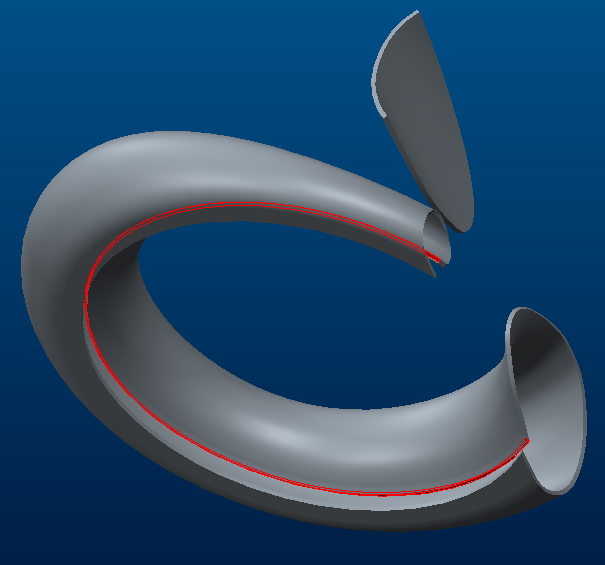

I tested your Testcase_Spirale_v20190520.iges surface model. I think it contains problematic geometry. To get thickened geometry, you have to repair surface model.

Suggestion:

1.] open Testcase_Spirale_v20190520.iges surface model

2.] create datum plane DTM1 offset from RIGHT

3.] trim model geometry using DTM1

4.] thicken current model geometry

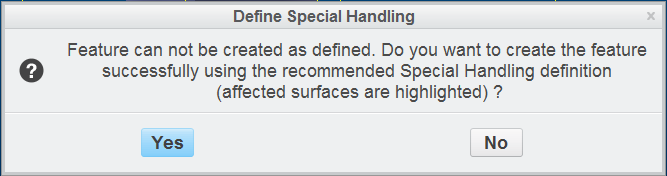

you will get following warning ... I guess it tells you that geometry is "suspicious"

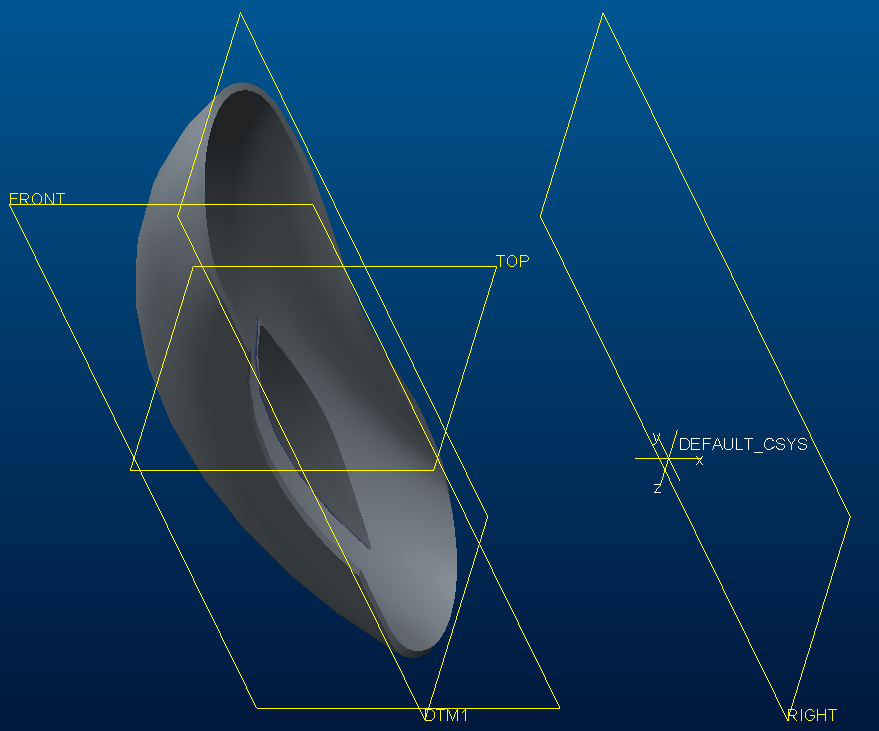

click YES, Creo creates solid geometry

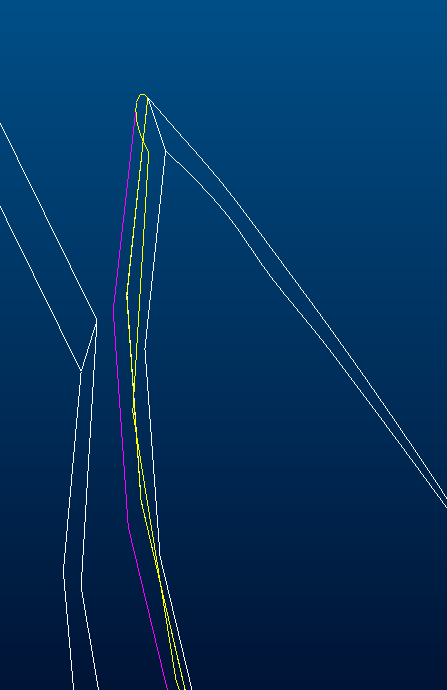

zoom in ... you will see problematic geometry (magenta and yellow color)

... now you have to resolve this problem

Note: You can modify dimension related to DTM1 to see more thickened geometry. If regeneration fails after modification then you know that you hit another problematic geometry.

Good luck ...

Martin Hanák