- Community

- PLM

- Windchill Discussions

- Configurable Assy Vs Family/Desing Table Vs OtherW...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Configurable Assy Vs Family/Desing Table Vs OtherWay (CATIA/CREO)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Configurable Assy Vs Family/Desing Table Vs OtherWay (CATIA/CREO)

In terms of practice, the use of Family-Table or “Option and Variants” looks very similar, but in this case I would like to post my plant situation.

In terms of practice, the use of Family-Table or “Option and Variants” looks very similar, but in this case I would like to post my plant situation.

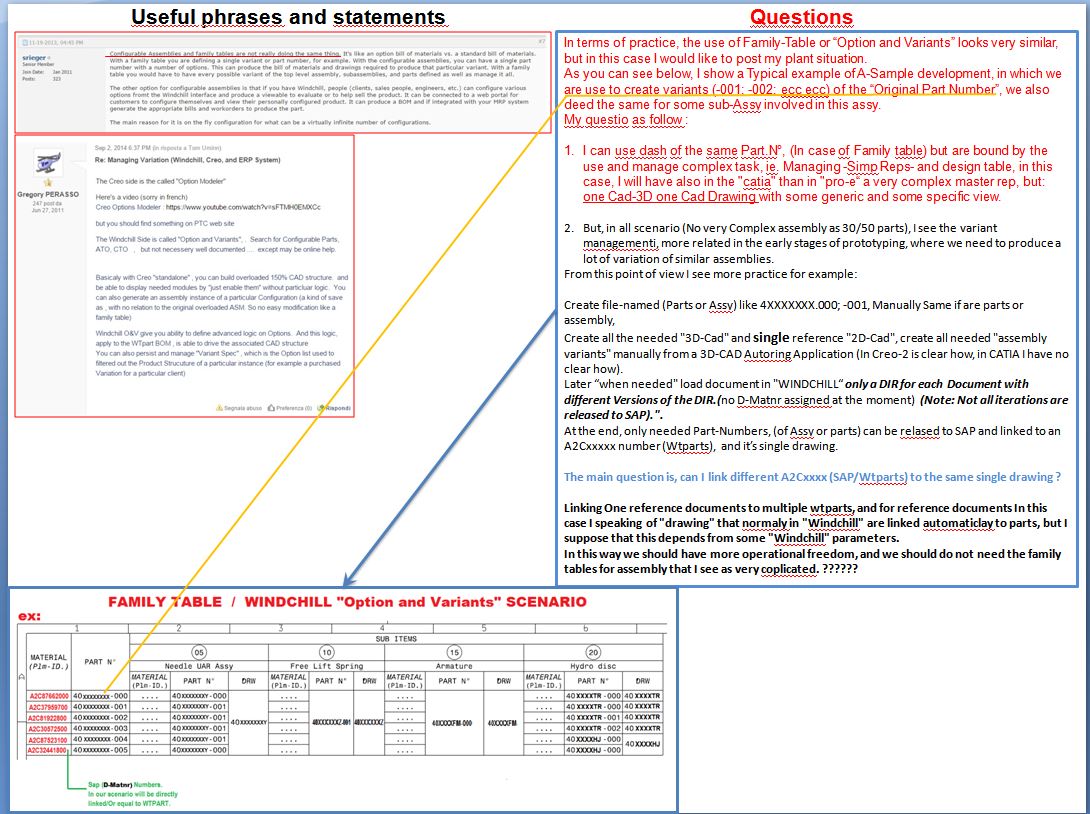

As you can see below, I show a Typical example of A-Sample development, in which we are use to create variants (-001; -002; ecc ecc) of the “Original Part Number”, we also did the same for some sub-Assy involved in this assy.

My questio as follow :

1.I can use dash of the same Part.N°, (In case of Family table) but are bound by the use and manage complex task, ie. Managing -Simp Reps- and design table, in this case, I will have also in the "catia" than in "pro-e“ a very complex master rep, but:one Cad-3D one Cad Drawing with some generic and some specific view.

2.But, in all scenario (No very Complex assembly as 30/50 parts), I see the variant managementi, more related in the early stages of prototyping, where we need to produce a lot of variation of similar assemblies.

From this point of view I see more practice for example:

Create file-named (Parts or Assy) like 4XXXXXXX.000; -001 Manually, Same if are parts or assembly,

Create all the needed "3D-Cads" and single reference "2D-Cad", create all needed "assembly variants" manually from a 3D-CAD Autoring Application.

Later “when needed" load document in "WINDCHILL“ only a DIR for each Document with different Versions of the DIR.(no D-Matnr assigned at the moment) (Note: Not all iterations are released to SAP).".

At the end, only needed Part-Numbers, (of Assy or parts) can be relased to SAP and linked to an A2Cxxxxx number (Wtparts), and it’s single drawing.

The main question is, can I link different A2Cxxxx (SAP/Wtparts) or diferent 3d CAD Parts to the same single drawing ?

Linking One reference documents to multiple wtparts, and for reference documents In this case I speaking of "drawing" that normaly in "Windchill" are linked automaticlay to parts, but I suppose that this depends from some "Windchill" parameters.

In this way we should have more operational freedom, and we should do not need the family tables for assembly that I see as very coplicated. ??????

Solved! Go to Solution.

- Labels:

-

CAD Data Mgmt

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Precedente | Successivo

Da: Gregory PERASSO

Posta inviata: Dec 5, 2014

Oggetto: Messaggio privato: Re: Ask for help

Yes it is correct

for me , a best practice for family table is to only use for building part families (nut , bolt, etc ...)

And not for managing Variation or Configuration. Especially if you want to connect CAD to WTpart

It is more reliable to do like you say. More simple from CAD point of view

But I prefer loose a little bit time in managing or dupplicating CAD (may be can have a look to inheritance instead of familiy table)

if the gain regardind the full process is better for the company

You data model is simple to undersand for any person in the company

Gregory,

your approach is perfect, but In our enviromet, R&D evry assembly change so fast in Numbers of parts Surface treating, Case hardening ecc. ecc. an So many people need to have access to the 3D and 2D, so I see the use of Family Table or Variation, generate a very complicated Master Rep, my concern is that non all the user have the capability to have a clear vision of That.

So we would like To create Different 3D models (numbers and Diff. WTPARTS number one To one), linked to 1 2D drawing.

Is this correct ?

OK so you're in normal and nominal case with Windchill

-Associate the 3D CAD to Wtpart with owner link. give you the ability to drive automatically the WTpart structure from CAD

-and associated with content link the CAD Drawing. (you can totally associate any drawing to any WTpart or any several WTpart. not necesaary to the WTpart that use the 3D model)

it is typically our case for family table. We create only one drawing on the generic , with a inner table with each dimension for each instance.

Each 3D family instance is linked to a different Wtpart

And we link this unique drawing to each Wtpart

Gregoy,

thanks for you suggestion, For us at the moment the solution :

- one 3D CAd model for one WTpart is perfect.

Hi Matteo

For the "one drawing to n WTpart", there's no problem . It is out of the box in Windchill.

for me best practice is to use the "content" link (in edit association action in the workspace or CAD DOcument menu)

But for the 3D. Do you mean same 3D to n Wtpart ?

if it is one 3D CAd model for one WTpart. no problem . it is also out of the box in Windchill (owner association)

if it is one CAD part to n WTpart. more complicated. but exist . Just that not fully released in Windchill 10.2. But works already pretty fine. If that case , I can provide you more detail

regards

Grgeory

Gregory,

regarding the question that I posted inside this forum "Configurable Assy Vs Family/Desing Table Vs OtherWay (CATIA/CREO)" can you help me, I mean, is there an example of configuration that you have encountered in the past similar to our:

Multiple Different 3D model number, Linked only to One 2D Drawing Number:

1 WTPART = 1 3D Model

1 WTPART = 1 3D Model } But only one 2D drawing

1 WTPART = 1 3D Model

Best Regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If I understand what you are trying to do, you want to link (Associate) multiple CAD Documents to one WTPart? I can't speak to the SAP side of things but I'm assuming that a WTPart would equate to an SAP Item Master entry.

So the answer is yes. You can set different types of Association (linkages) between WTParts and CAD. There can only be one "Owner" (CAD drives structure and attributes), but there are other types as well (Contributing Image, Image, Contributing Content, Content). I encourage you to refer to the Help files to understand the differences (I don't have exact differences in memory). A word of advice, only one of Owner or Contributing Image Association types.

I would caution against the use of family Tables for complex assemblies (best suited for same shape different size like fasteners etc.).

Options and variants is a way to define Configured WTPart Structures (BOMs) based on choices and selection logic. There is an add-on module for Creo that will drive the Windchill configuration into the CAD model.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Keir,

thank you very much for your response, before to give a comprehensive answer to your suggestion, I will deepen on the help file to understand better the different types of associations, and the relative conjunction from SAP side.

But you have hit the mark, the main question is to find a best practice, to avoid the generation of a lot of different drawing numbers, at least for the early stages of development, this also because we are in the middle, of a project for the personalization, by PTC and Head quarter in Germany, In this phase only macro problem (More related plus on simple SAP production management, and it's products life cylce management are the focus, but not all the aspects and problems on the start-up phase of development more over related to different plants and locations.

Thank you very much, I appriciate however, that we will continues to deepen on this topic, even after my comprehensive answer.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Matteo,

You may want to use one WTPart represent the final solution that will carry the ID Number that will be used. To capture different design alternatives you could give the CAD files a temprary Number and use rename later when a single alternative is selected. (If the rename Action is restricted, then you could do a Save As of the selected final design model). I would restrict the use of the "temporary ID's" to internal use. When communicating externally the need for unique and definitive identification may outweigh the "cost" of using up Drawing Numbers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm not sure if it's helpful or not, but there was a discussion a while back on configuring Windchill to allow multiple owner links from one CAD document to multiple WT Parts.

http://communities.ptc.com/message/248564#248564

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tom,

thanks for you suggestion, but I need to go deeper on this prblem on help file of windchill, but for describe better our problem I explain as follow:

- I need to create a basic (2 To 6 Variation) generic Assy 3D models (without Family Table or Option and variant) MANUALLY but I want to Call with same part number ie. 4000000Y-000, -001, -002 ecc ecc. Manually because sharing assy with master rep so complicated... I do not se for us a good practice for a sharing environment.

- Create (even manually) a 2D Cad Drawing named 4000000Y , add the necessary views, on some table in the drawing, like in example that I enclose in this topic.So in this case I have this situation. ONE DRAWING Multiple differents 3D models but named with unic reference key 4000000Y and distingued by -000,001 ecc.

At this point I have to interface this structure with windchill, so check-in - check-out, what's happen now ??

3. Before a (My company defined) level of maturity (Not developed, in-work, ecc ecc) I am free to manage a varieties of changes iterations without loading material to SAP (with all the work associated with) (in this phase we do not have wtparts linked to SAP).

The main reason is to manage the lack of our sample lab to use of windchill, so to not create a lot of varieties of WTPARTS numbers (If that is the way) instead of model named numbers (With the scheme described above) :

One way should be.... after the instruction of our sample-lab of use of windchill:

- Use multiple WTparts numbers to distinguish the assembly described in that single drawing.In this case it doesent matter if I use the scheme like above 4000000Y-000, -001, -002, because at he end what guide all are wtparts numbers.(this involves a complete integration of windchill with all ours life cycles schemes)

- also Because we would create a separate container (Separate form local production ERP) to manage all aspects of Sample-Lab management (purchasing, supply, warehouse).

Other way is to link to multiple wtparts but without thaking WTparts numbers withhold this task in a manner that I can manage the early stage iterations of drawing, and making 4000000Y-000, -001, -002 numbers guiding manual bom managements; manual purchasing and supply management; manual warehouse manegement, before going on sap to take material numbers to link in WTparts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Precedente | Successivo

Da: Gregory PERASSO

Posta inviata: Dec 5, 2014

Oggetto: Messaggio privato: Re: Ask for help

Yes it is correct

for me , a best practice for family table is to only use for building part families (nut , bolt, etc ...)

And not for managing Variation or Configuration. Especially if you want to connect CAD to WTpart

It is more reliable to do like you say. More simple from CAD point of view

But I prefer loose a little bit time in managing or dupplicating CAD (may be can have a look to inheritance instead of familiy table)

if the gain regardind the full process is better for the company

You data model is simple to undersand for any person in the company

Gregory,

your approach is perfect, but In our enviromet, R&D evry assembly change so fast in Numbers of parts Surface treating, Case hardening ecc. ecc. an So many people need to have access to the 3D and 2D, so I see the use of Family Table or Variation, generate a very complicated Master Rep, my concern is that non all the user have the capability to have a clear vision of That.

So we would like To create Different 3D models (numbers and Diff. WTPARTS number one To one), linked to 1 2D drawing.

Is this correct ?

OK so you're in normal and nominal case with Windchill

-Associate the 3D CAD to Wtpart with owner link. give you the ability to drive automatically the WTpart structure from CAD

-and associated with content link the CAD Drawing. (you can totally associate any drawing to any WTpart or any several WTpart. not necesaary to the WTpart that use the 3D model)

it is typically our case for family table. We create only one drawing on the generic , with a inner table with each dimension for each instance.

Each 3D family instance is linked to a different Wtpart

And we link this unique drawing to each Wtpart

Gregoy,

thanks for you suggestion, For us at the moment the solution :

- one 3D CAd model for one WTpart is perfect.

Hi Matteo

For the "one drawing to n WTpart", there's no problem . It is out of the box in Windchill.

for me best practice is to use the "content" link (in edit association action in the workspace or CAD DOcument menu)

But for the 3D. Do you mean same 3D to n Wtpart ?

if it is one 3D CAd model for one WTpart. no problem . it is also out of the box in Windchill (owner association)

if it is one CAD part to n WTpart. more complicated. but exist . Just that not fully released in Windchill 10.2. But works already pretty fine. If that case , I can provide you more detail

regards

Grgeory

Gregory,

regarding the question that I posted inside this forum "Configurable Assy Vs Family/Desing Table Vs OtherWay (CATIA/CREO)" can you help me, I mean, is there an example of configuration that you have encountered in the past similar to our:

Multiple Different 3D model number, Linked only to One 2D Drawing Number:

1 WTPART = 1 3D Model

1 WTPART = 1 3D Model } But only one 2D drawing

1 WTPART = 1 3D Model

Best Regards