Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- PLM

- Windchill Discussions

- PDMLink Process Management for Change

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

PDMLink Process Management for Change

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

PDMLink Process Management for Change

You can read the Enterprise Tip of the Month here also authored by Brian Muttonen and you can also read the Desktop Product Focus of the Month here and the Desktop Tip of the Month here authored by Ryan Butcher.

| PTC Technical Specialists Newsletter - February 2011 |

Product Focus : PDMLink Process Management for Change |

|---|

One of the forgotten tools of PDMLink is workflow. In order to highlight workflow we will use change management generically. Change Management is a process that companies undergo in order to cause change to an existing product being produced by manufacturing. When a product is already being manufactured, suppliers, manufacturing plants, purchasing people, test and validation, product support, sales, and marketing already know what to do and what is available. Now if a change is recommended everyone understands that each of these disciplines needs to gain knowledge of the change. They will also need to share knowledge so that the change is not detrimental to any of the disciplines or the product.

PDMLink offers a number of areas to help in this interaction and ways to capture and transfer knowledge to those in need of it. We are going to focus on highlighting two benefits:

- the value of the complete data model and

- the value of managing the process via workflow within PDMLink.

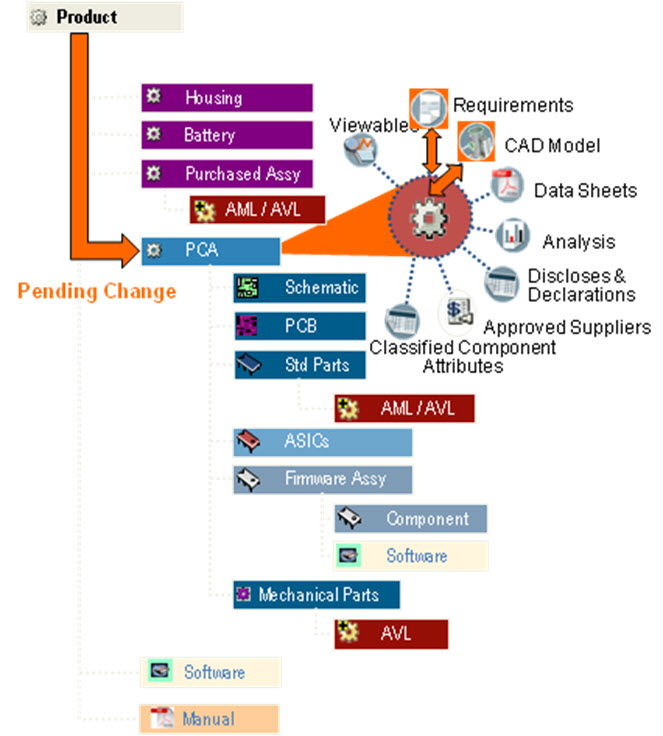

As you can see in the following picture PDMLink offers the opportunity to manage the data that is required to understand a product, including worksheets, analysis, requirements, testing, suppliers, and various other formats. The combination of these formats allows individuals within the process to make knowledgeable decisions. The data elements also allow them to document why they made their decisions.

The next benefit that we would like to highlight is getting the information to the correct people. With the workflow engine within PDMLink we can set up processes that span from very simple to extremely complex. The most important thing to remember with regards to workflow is that you want to use it to standardize a process and then to monitor that process for continuous improvement ideas. As in manufacturing, development also needs to gain consistency in order to adhere to the high quality standards of today.

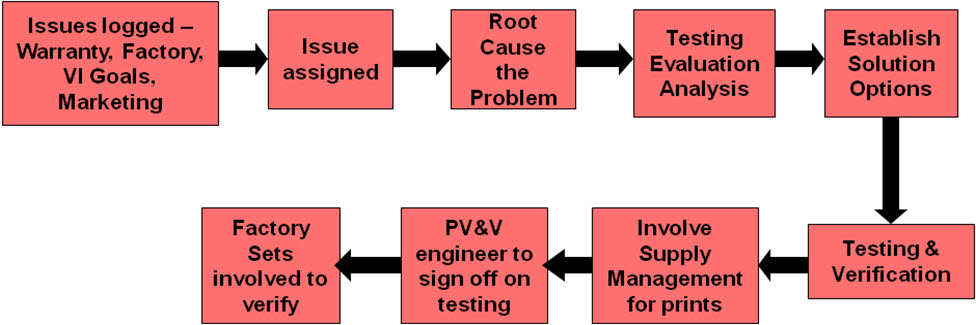

Workflow allows a company to automate a process similar to the following:

It also allows one to transfer the critical knowledge to the individuals included in the workflow who will either need to make a decision or do some type of work. The combination of automated workflow and a complete data set with the correct knowledge included will allow the correct people to get involved in the process and be delivered the information they need to do their job. The goals are to reduce long loopbacks, get the required knowledge in decision maker’s hands before they make the decision, and to improve the quality of the process.

In the Tip of the Month we will talk about a way to put in place the tools to come up with a continuous improvement process for your workflows.

You can read the Enterprise Tip of the Month here also authored by Brian Muttonen and you can also read the Desktop Product Focus of the Month here and the Desktop Tip of the Month here authored by Ryan Butcher.