Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- PLM

- Windchill Discussions

- Best Practice to Manage Wire in Windchill BOM

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Best Practice to Manage Wire in Windchill BOM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Best Practice to Manage Wire in Windchill BOM

Hello

We have some tricky situation here.

We have wires created in Creo and as per process it generates auto associated BOM in Windchill. For many projects, wire specifications, sizes and length are same. However, shapes vary based on product need. Therefore, we need to create multiple Creo parts according to shapes and it generates multiple Windchill parts for same wires.

Does anyone have better solution to manage this ?

- Labels:

-

BOM_Platform Mgmt

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We use a number scheme that allows us to search in Windchill for these types of flexible components where using an actual flexible component is not practical.

- For parts used in different configurations (wire routing, hose routing, etc.) Use the component number first, a dash, the assembly number, a dash, and then a sequence number.

- Wire base number: 7409878-04

- 7409878 is a base wire specification

- 7409878-xx, xx designates a sequential number for wire colors

- May use vendor color codes for xx

- Used in Assembly: 1025643

- Routing Sequence: W#, H#, P#

- W for wire routings

- H for hose routings

- P for flexible pipes

- Wire base number: 7409878-04

- Final part number: 7409878-04-1025643-W3

- Third routing of wire 7409878-04 in assembly 1025643

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is very good suggestion. However, we end up creating multiple parts in Creo. We are looking to create single part in Creo or way by which production/store team needs to keep inventory for one part.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

One thing I forgot to mention is that we use a part relation in the CAD files so only the wire number shows in the BOM. No matter how many wires in your assembly, they show as a single line in the BOM.

PDM_NUMBER = extract(rel_model_name,1,10) works for our numbers.

We then use PDM_NUMBER in the BOM for the number field.

For wire 1254561-03-1254895-W3.prt, we end up with PDM_NUMBER = 1254561-03.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, We have the same problem for the timing belt. Because they are in different shape on different machine, but the circunference are the same.

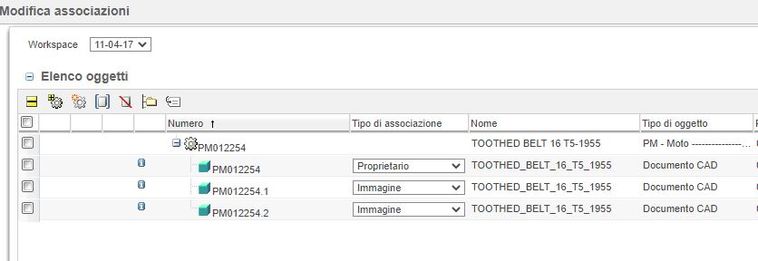

In this case we create a new cad part and manually we associed it to the original part, in this way we have many cad part and one part that can be used in a BOM.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Both replies are good suggestions. You have flip the association to an image link and realize that you have a model that is just a model but the part object is what you order and put on the BOM. For a flexible model that can take any shape, the model will be specific to the assembly that its in so including the assembly number in the CAD file name and number make sense. This will work for gaskets and fixed length cables. Wire will usually be a infinite length part and most likely part of a Pro/Cable assembly (spools?). Either way, if you are making a physical CAD model for it, same rule applies.

For each CAD model that represents the same BOM Part, you can associate to the same Part object via image links. One Part can have many, in this case, infinite CAD models for it. You may have to also edit the units and quantity from 1 each to something more appropriate like 10 inches for wire. You can do that on the BOM.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I should also add that there is a technique of using a Part number parameter for these type of models. This overrides the default rule of using the CAD filename to autocreate a part object of the same number. If that part exists, it will link to it. The parameter needs to be configured in PDMLink and designated in the model. There is also parameters that can be setup to tell PDMLink to never autocreate a Part object if that value is set to True. This allows you to make that manually association to the right part and avoids creating junk parts.