Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Collecting Dimension Results from Simulation, ...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Collecting Dimension Results from Simulation, with associated features

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Collecting Dimension Results from Simulation, with associated features

Hello all,

I am using Feasibility/Optimization to simulate a gage interacting with the surface of a part. The features we are gaging are taper thread holes, and they repeat on the part, but part geometry creates a different offset distance between the gage's point of contact and the gage line in the hole.

When I perform the simulation, I'm left with an offset dimension that represents the distance we need to use to set the gage value for part acceptance target. I'm looking for a way to extract these linear dimensions and the features at either end to create a table with columns: Gage No. XX, Feature Name YY, Offset Dimension Z.ZZZ.

Can anyone offer a suggestion for how to extract this data?

Thanks.

- Labels:

-

2D Drawing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is incredibly cumbersome, a lot of work, hopeless.

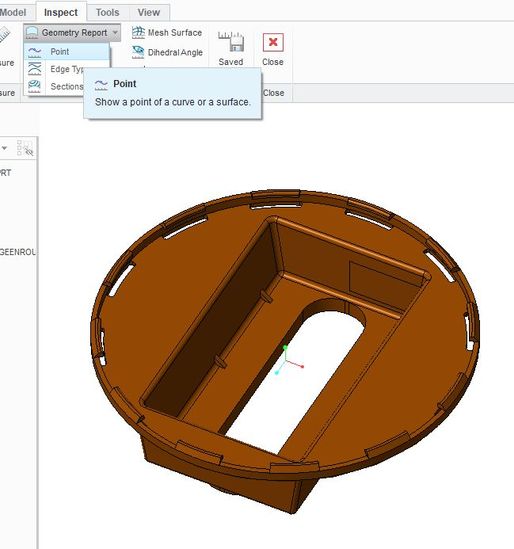

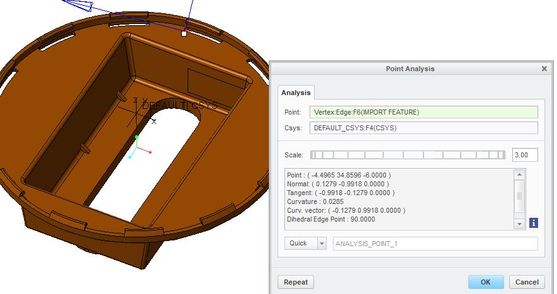

Look at the pictures, you can find point coordinates through Inspect-geometry report- point.

The top line, behind point gives x,y, z coordinates for tghe vertex you pick.

Good luck!

Regards

Erik