Community Tip - Your Friends List is a way to easily have access to the community members that you interact with the most! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- How to pattern a curve attached to 2 points that h...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to pattern a curve attached to 2 points that have each been pattern tabled?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to pattern a curve attached to 2 points that have each been pattern tabled?

Hi,

I have a number of individual points that I would like to pattern with individual pattern tables and then create a curve thru a point in each set of pattern points and then reference pattern those curves to the table pattern points.

Is this possible and how?

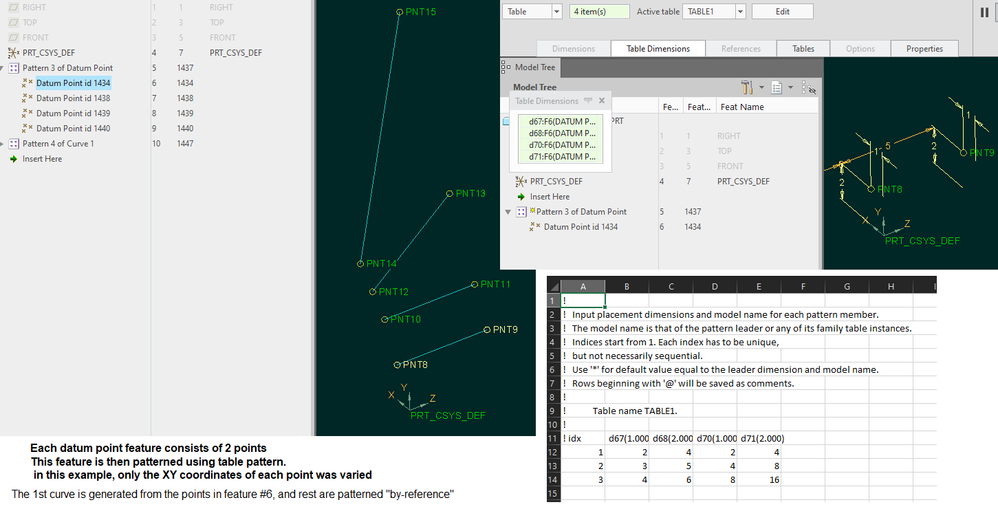

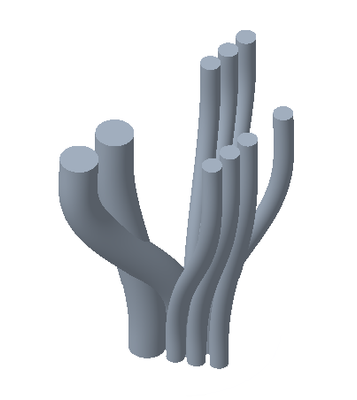

In the picture below I have created 2 offset coordinate system points and have patterned them separately using separate pattern tables. I then created a curve thru the 2 points I created and then referenced pattern the curve. the pattern of curves should be separate straight lines. For example the second curve should be going from pnt1 to pnt10 and not from pnt1 to pnt9 and so on.

Any ideas on how to fix this issue?

my ultimate goal is to use a family table to swap out the pattern table to change the position of each row of points.

Thanks for any help you may provide!

Don A

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't think there is a way in Creo to do a "multi-pattern-reference-pattern".

But can you perhaps manage the pattern of the point coordinates using a single pattern table?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo 7 model posted for reference.

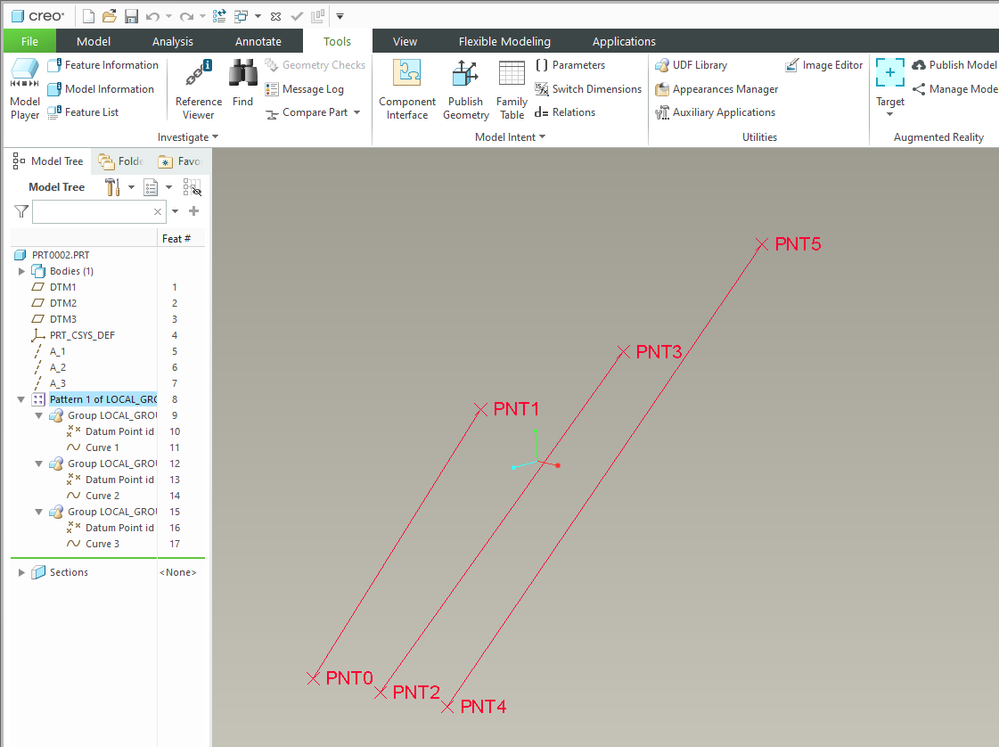

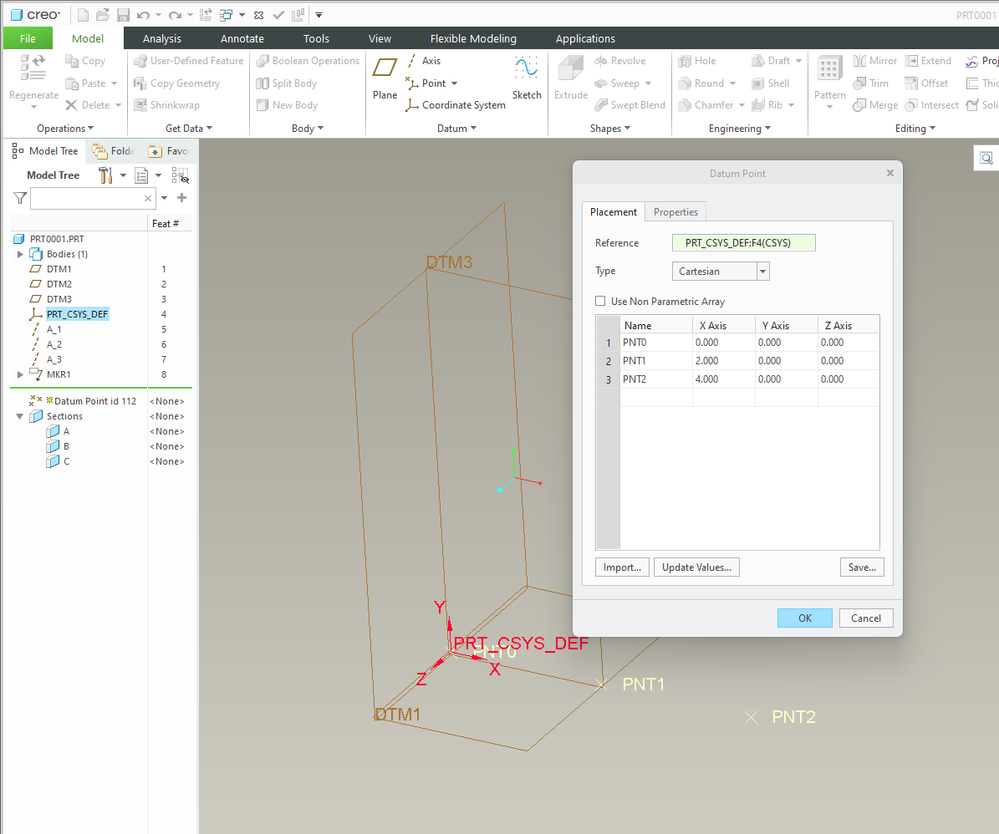

This appears to enable the goal to pattern the features as described. The model uses offset from csys datum points to define the proximal and distal ends of the curve that will serve as the pattern leader. A curve through points is created for the pattern leader. These two features are grouped and then patterned using the pattern table functionality.

This is an alternate way to implement the desired curves mapped to the points by using datum points offset from csys rather than a just pattern table. I would not use a family table to modify the model, but it may work for you.

Note that you can import the coordinate values if you use an offset from csys datum point array feature. I would import .pts files used by the datum point features to update the model rather than a family table. There may be a way to avoid the pattern table altogehter and use the offset point array only but I am not seeing as of now. I will consider it again at a later time.

About Datum Points Offset from a Coordinate System (ptc.com)

This is using a pattern table to add sets of points and curves as pattern instances and can be extended to N curves as required. The pattern table is used to add the coordinate values of the proximal and distal points of each curve instance in the pattern.

Offset from CSYS datum array with table entry. Note the option to import the coordinates.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It appears that the solution you and Pausob are proposing are the same solution and might work for what I'm trying to do but would require a lot of work determining the locations for all of the points for both states of the component (component drawing and assembly drawing). Looks like what I would like to do may not be possible.

The component model I'm trying to make has wire leads that start at different locations at the top of the image below and will have straight wires for the component drawing with 2 wire lengths. I need to be able bend the wires in a curve and bundle them in a circle along with staggering the ends of the wires so the component may be spliced into the harness at the assembly level. The other need was to have the point clouds for each section tied to a coordinate system so the routing of the wire may be changed at the assembly level for the component. Note the component wires will be tied to a Creo Cabling harness at the assembly level.

I will try and share more images once I have the models more complete.

Thanks,

Don A

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hmm, I assume that the the proposed solutions are more "difficult" from your intended solution, because all points have to be specified in terms of a common coordinate system - and yet the two sets of points (1st to specify the cables' start points, and 2nd to specify their end points) are each more easily expressed in terms of their own coordinate systems, and the transformation between these two coordinate systems is determined by the assembly context?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If this is a cable routing problem (requiring a flat harness drawing) are you not able to use routed systems module for cable routing?

If you cannot or do not want to use cabling module, I think it is possible although more work to set this up such that the point pairs for each cable can be managed by Creo using the pattern type I posted in the model above. Assuming you are defining the proximal distal points in a part or assembly you can track and update the point locations relative to a chosen reference frame (csys) by using analysis features and relations.

I would need to better understand the inputs to the pattern generation and their source to offer more insight.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi TBraxton,

I would prefer to use Creo Cabling for this problem. Can you verify for me that the following are allowed in Creo Cabling?

I have the following file levels and required drawings:

1. Electric Motor assembly that will have pigtail wires coming off it 36" long with 0.25" stripped of the ends of the wires and the wires for this component drawing need to be shown with the wires in a straight line on the drawing. These wire need to be shown in a ribbon flat line on the drawing to make it easier to call out each wire.

2. Sub assembly drawing of the Electric Motor assembly with the Pigtail wires length cut to cut to varying lengths with 0.12" stripped of the wire ends , splice connectors added somewhere in the middle and wires spliced between the splice connectors and the panel connector that's added to this level. multiple heat shrink tubings need to be applied at this level (one long one over the full length of the wires and 2 shorter ones, one over the connector and one where the wires come out of the motor. Note wires at this drawing level need to be shown in a straight line too. Wire in this assembly need to be bundled in round shape for the heat shrink.

3.Top level assembly level and drawing: at this level the finish assembly in step 2 above will need to be assembled and have the wires, heatshrink, bend to match up with final motor installed location and connector installed location.

Is this possible using Creo Cabling?

Thanks,

Don A