Community Tip - You can Bookmark boards, posts or articles that you'd like to access again easily! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- LDA: static analysis with more than one output ste...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

LDA: static analysis with more than one output step used for optimisation study

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

LDA: static analysis with more than one output step used for optimisation study

Hello again.

Some time ago, I was stucked with next problem: model/assembly parameter as variable in a optimisation study

The original problem is now solved and now I started to research (because i want to learn) some more on my own (it is not task in my job any more)...

The task I choose to solve is to optimize the distance of snap, to ensure prescribed pull off force. My idea is to choose "Optimisation" or "Feasibility study", where the design limit will be prescribed reaction force (where the constraint is) and the variable will be the length of the snap.

But at first I have to do static analysis.

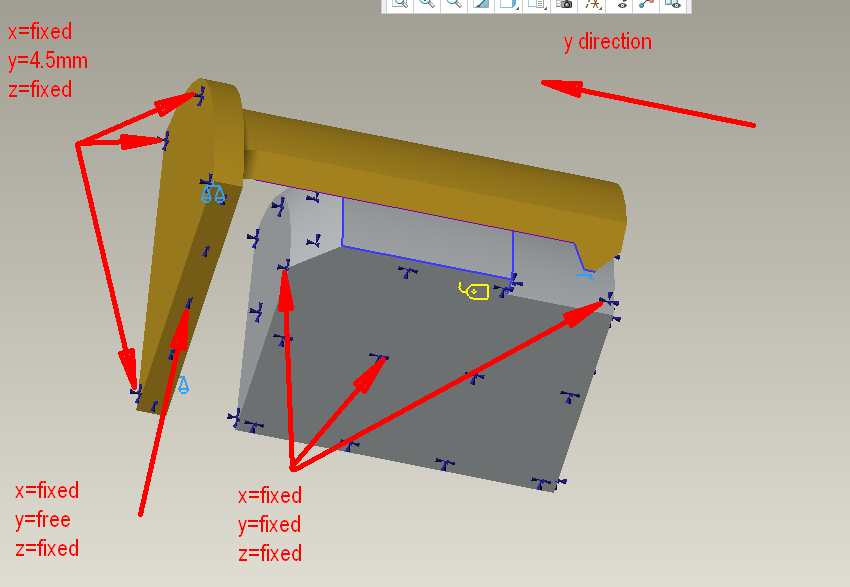

So now I have situation constrained exactly the same as in the upper problem:

Measure "ract_at_const_mag" is also added to the surface where the snap is pulled. The measure is: reaction at constrained.

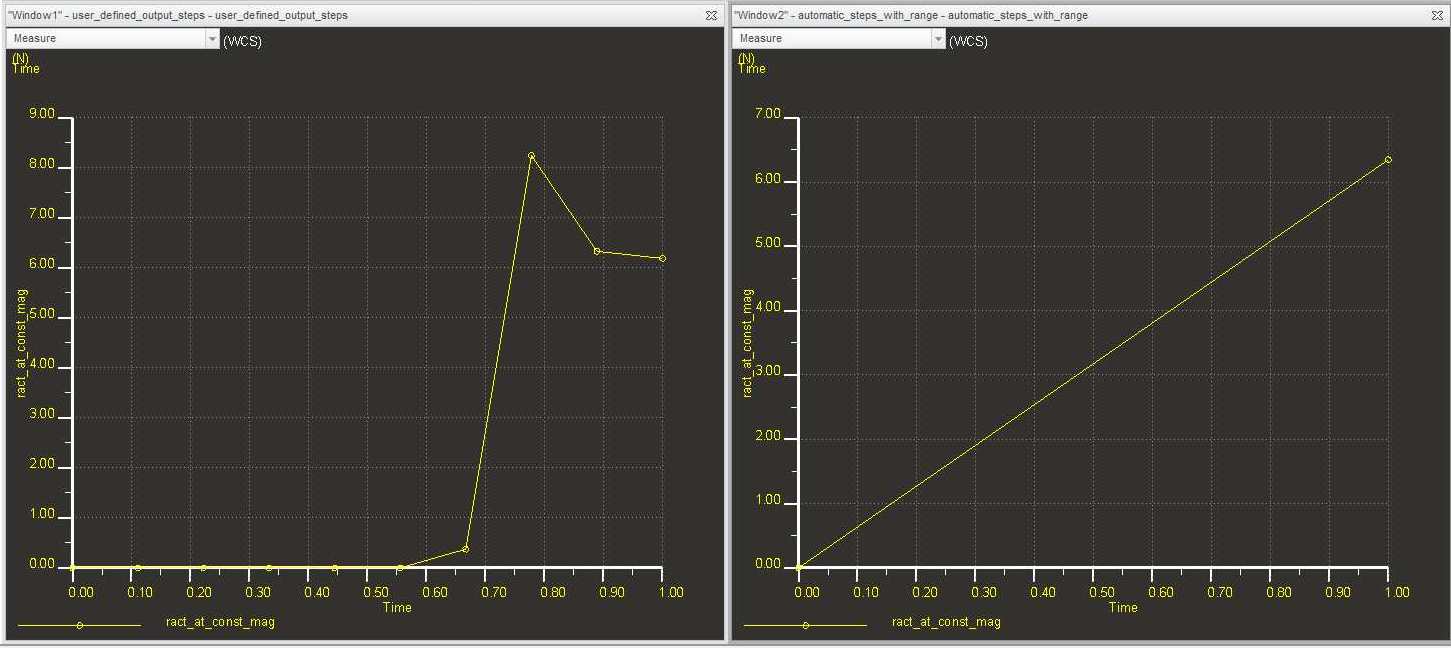

And then I start the analysis with Output setting: "Automatic step within range" (shown bellow) and another analysis with all exactly the same settings but output settings, where I choosed "User defined output steps" and "Space equaly".

If I compare results: strains, stresses,... it all looks practically the same. Fine.

But if I check the measure "ract_at_const_mag", then I get:

1.) Why do I get the difference?

2.) And how can I convince Simulate so I can use analysis with more than one step (with User defined output steps) into "Optimisation analysis"? Bcause it seems to me that graph of "user-defined output_steps" analysis is more realistic...?

Many thanks for your help in advance.

BR, Franci

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Assembly Design