Community Tip - Your Friends List is a way to easily have access to the community members that you interact with the most! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Losing Mechanism functions

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Losing Mechanism functions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Losing Mechanism functions

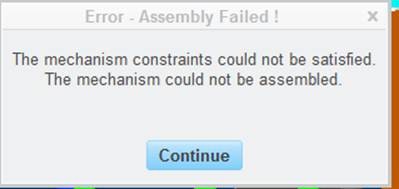

We are experiencing some weird issues with Mechanism lately. It seems that randomly (we can't find a reason) we will lose the ability to "drag components" in our assemblies. For example we use a lot of clamps and we like to be able to open and close them in the model to check for interferences. But sometimes we lose the ability to drag components that were constrained with Mechanism. Attached is an image of the error that we get, when you click continue it opens the "drag" box, but you are unable to actually drag any of the components. The only way we have found to fix this is restart Creo.

Has anyone had this happen before and does anyone have any ideas what is causing this?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've seen this all too often when I finally corrected this with snapshops and enabling regen values in the constraint definition.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Do you know what is causing this? Can you give some details about what it is you do to work around this error?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We have this happen all the time when dragging. It's like the software can't keep up with all the different changes that need to happen everywhere and things become disconnected. We've adopted the approach of adding a motor, running an analysis, then simply playing the analysis back and forth instead of dragging.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Like Tom said, the software gets confused. Dragging can make very wilds decisions that cause other constraints to fail.

Snapshots are hard to deal with during development because they go out of date too easily with every change. But on a stable design, they are nearly imperative. If you want a mechanism analysis to return to a known state, you need these snapshots there as well. All in all, this one tip alone has saved me huge levels of frustration.

The second part is limiting the motion in the assembly constraints. Anytime you use a mechanism constraint, you risk the ability to drag something to their extreme which may not be compatible with another linked components. Typically this happens when a plane "flips" during the motion. For instance, linking chain links can flip onto itself without hesitation just by dragging the chain back and forth (like pushing a rope). Limiting the angle will avoid this clipping degree of freedom. Most mechanism constraints also have the ability to set a regeneration value. This is helpful, but do know that sometimes this gets in the way (can create its own error). This only tries to restore the "default" position when the assembly is regenerated or opened. This ensures the part will always be in a good state. Unlike snapshots, this is more stable since it doesn't just take a ...well "Snapshot". It is an evaluation condition.

If things get out of whack, and regen won't fix it, then try a verified snapshot. Just remember to redo your snapshots often in development! We need a prominent button for "default snapshot update"!

This is what you are looking for in your mechanism assembly constraints: