Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Need suggestions for an alternate process to patte...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Need suggestions for an alternate process to patterning within sketcher

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Need suggestions for an alternate process to patterning within sketcher

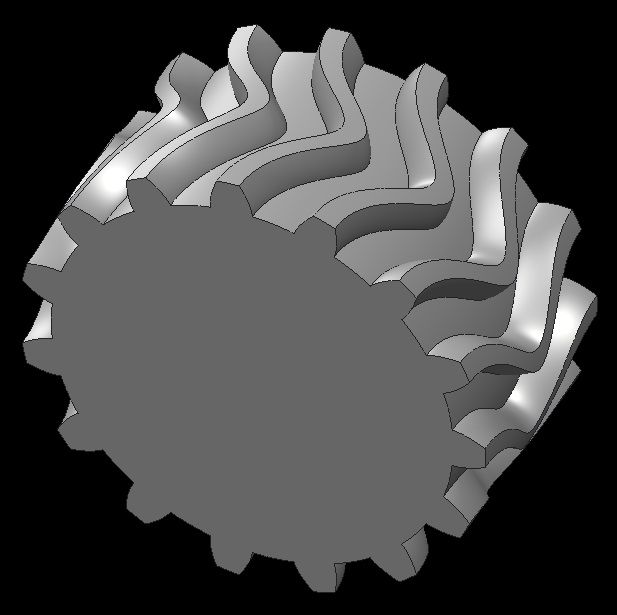

I recently followed a youtube tutorial for creating a pinion gear. (sketch a circle/sketch a tooth on diameter of circle/create 4 center lines/mirror tooth over 4 center lines so you have 6 equidistant teeth / delete line segments / blend - import sketch, scale down, rotate, repeat / complete blend) basically a twisted gear.

Instead of just 6 teeth I would like to do 50. It would be tedious to create dozens of center lines and 50 mirror steps etc. I thought if I patterned a single tooth about an axis I could easily create 50 evenly spaced teeth.

The problem I have now is the original sketch (single circle and tooth) and the patterned teeth are not part of the same sketch and therefore are not a closed shape suitable for using in a blend. It would seem a pattern function WITHIN sketcher would solve this but that seems like a no no in Creo. Can someone suggest how I can achieve this? Basically I need to make a sketch and a pattern somehow merge together so I can modify it as I would a single sketch.

Thanks!

EDIT:

The only work around I've found is to create a new sketch on a new plane, project the existing sketch and pattern onto this new plane/sketch and now it behaves as "one sketch". kind of clunky.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you really needing everything to be in one sketch? Why not break it down to one tooth profile. If you are trying to model a 3D part, it's not ideal to try to do everything in one sketch. If you were able to create one tooth profile, create your blend from that, then you can pattern the tooth feature around an axis.

I may be way off on my response, if so, maybe you could clarify your question.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you really needing everything to be in one sketch? Why not break it down to one tooth profile. If you are trying to model a 3D part, it's not ideal to try to do everything in one sketch. If you were able to create one tooth profile, create your blend from that, then you can pattern the tooth feature around an axis.

I may be way off on my response, if so, maybe you could clarify your question.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's definitely the simple approach my brain was completely missing. I'm an EE so that probably explains it. I created my single tooth sketch, completed my blend and then patterned the tooth. This worked well for small numbers of teeth, less than 6. As I increased the pattern above 6 it began taking Creo a long time to regenerate and most of the time it just plain locks up. So this technically works though Creo seems to be working really hard.

EDIT: OK that was my error, I was forcing the pattern to do 10 teeth at 90 degrees. Once I selected for it to be spread out over 360, it regenerated fine.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, not to bag on you Sparkies TOO much..... 🙂

Also, doing a geometry pattern will help speed things up a little. Not as much as I think it should, but every bit helps. Also, like I said, how exact does this gear need to be? I have a way of generating an involute without using a curve by equation and CS, but with any complex surface like that it's a big file. I did a kind of double herringbone design for, 20 teeth I think, and man, it was 68+mb!

Best of luck!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It doesn't need to be very accurate at all. I'm just trying to bone up on my Creo skills by trying to draw a variety of different mechanical/electro-mechanical devices. I'd like to get to the place where when I look at an object I know how to approach drawing it instead of depending on youtube and google university!

Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Then it's easy, in any drafting book, and online, there's figures showing how to approximate an involute toothform, if I remember (my Olde Drafting Book is packed) it's just an arc from the pitch circle out, and a line from the pitch circle in, with the location of the arc determined by the pitch circle diameter, and the number of teeth.

I figured out how to do a true involute from the bottom of the tooth out for fun, without using a curve via equation, but the file is a monster (100 meg for 19 teeth!). I'd like to do a direct comparison between the 2 methods to check file sizes. I didn't have any actual gear tooth data to use to define the involute, so I just fudged it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There's no easy answer to this. First, there are plenty of creo gear models on the web. Also, how accurate does this have to be? Does is just have to LOOK like a gear tooth or does it actually have to be accurate enough to hob the gear from?