- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Hiding axis in the drawing

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Pro/PIPING and BOM-table repeat regions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Pro/PIPING and BOM-table repeat regions

- Labels:

-

2D Drawing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Maurice,

I see your last post is quite long time ago, so by now you may already have the answer. What you need to do in order for any ProPipe paramters to show on a BOM, is a Parametric Report or ProReport. You need to have the hose/tube activated for this. Under the Piping Menu you go to INFO>Report Pipeline> Select "Bend Location" under Info Type, and UNder Definition you will select the Segment that you want info about, and then the Coordinate system where you want these coordinates to start from. Also make sure you have selected "Designate for Report Setup", after selecting the Coor Sys and clciking Done/Return the report will display in the middle for Results, then you go to the bottom of the dialog box and type the name, and save it, because this is independent and embedded in the file. After doing this, all this parameter or any other similar ones shall show up on the BOM and the way you have it set up.

I know your post if from April, but one never knows, so I hope this helps at least a little.

Laura

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I find that if you place the piping run/extend on a layer then turn that layer off it works quite well, otherwise the green piping run lines show up on drawings.

Give it a try

Dennis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Any chance you found a solution for this? It's obvious the pipeline that the solid belongs to isn't completely lost when you create the solid, as it still shows the solid pipes under the correct pipeline when you look at the Pipe Solid Manager. It seems like it should be a simple solution.

Anyway, I came up with one, but it's not the MOST optimal.

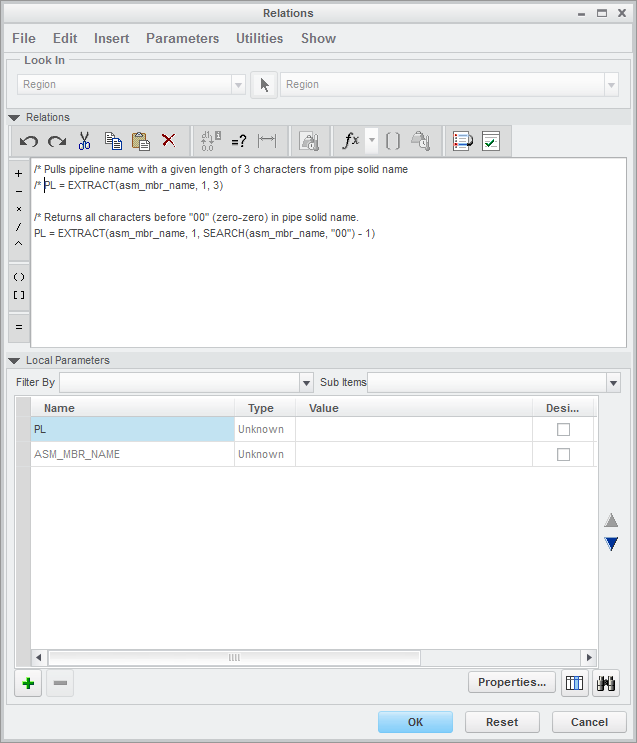

When you're creating pipe solids, you let them take their default names, with the pipeline name at the beginning of the solid's name. Then set your repeat region to asm.mbr.name. Then go into your repeat region's relations manager. Add a custom parameter below the relations window (I called mine "PL"). Then just use an EXTRACT() function in your repeat region's relations to pull characters from the pipe-solid's name. If you use the same function for multiple different pipelines, you just have to change the EXTRACT() arguments to adjust for the pipeline name's length (in characters). OR, if you know you'll never get into the thousands of pipe solids per pipeline, and you never use zero's in your pipeline names, you could use SEARCH() to look for the first zero in the pipe solid's name. Get creative with your string functions.

Examples (I commented out the first one as I'm not using that in my model) :

Then you just set your repeat region to rpt.rel.PL

Here's a list of string functions you can use (Page called "Operators and Functions for Strings", in the Creo help files, in case the link ever gets broken.):

http://support.ptc.com/help/creo/creo_optm/usascii/index.html#page/optm/options_modeler/fund_seven_sub/Operators_and_Functions_for_Strings.html