Community Tip - Have a PTC product question you need answered fast? Chances are someone has asked it before. Learn about the community search. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- SMOOTH_SHARP_CORNERS

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

SMOOTH_SHARP_CORNERS

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

SMOOTH_SHARP_CORNERS

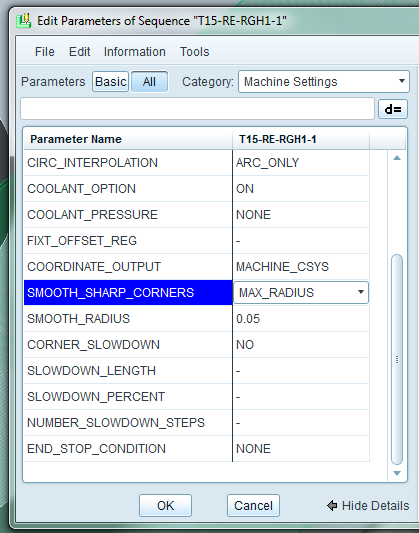

So I want to know if others use this option or ignore it. I have used this option for 3 axis milling Roughing and Re-Roughing cycles for awhile now and have noticed some issues with remaining material. By that I mean that when a Re-roughing cycle is calculated it seems to not account for the material that remains when the roughing pass is modified by this option. This issue has lead to broken and badley worn tools in my shop. I have used mainly MAX_RADIUS and (SMOOTH_RADIUS = .05). What has been your experiance with this option?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

nick,

i do use on occasion but in 2 axis roughing only. i use constant radius and choose a small amount <.05 to keep the transitions from being sharp.

i rarely use roughing and re-roughing as i gravitated to vlm roughing early on and have stayed with it. When i did try the rghing/re-rghing i did not like the toolpaths that where generated - especial in the re-rghing. I should spend more time with them as maybe they have improved since i last used them.

overall, are you happy with the rghing and re-rghing in Pro?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

For the geometry that I need to produce I find the roughing and re roughing to be semi reliable once you get the right parameters set. There is still the issue of air machining and excessive retracts but I have never like the local milling toolpaths. I will rgh with a 1/2 bull re-rgh 1/8 ball to a 1/16 to a 1/32. The small sized BEM are what lead to this discussion I need the re_rghing toolpahts to be quite accurate. All that being said I do hope to see some new toolpaths in the next few versions of Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

yes, some new functionality in the toolpaths is long overdue. We have a guy here using Mastercam X5. The rest milling toolpaths that are being created are no joke - very efficient.