Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: creo 2.0

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

creo 2.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

creo 2.0

anybody know how to get factor of safety of part after analysis ??

here , I want to get fos of part.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Factor of safety is defined as FS = allowable value / actual value

So in your example, suppose the allowed deformation is 8mm, then your FS on deformation = 8 / 4.2 = 1.9

For stress, the material's yield stress is usually used as allowable (FS on plastic deformation) or sometimes the material's ultimate stress (FS on failure).

Or if your part is loaded repeatedly, you might want to calculate the FS on fatigue. This can get complicated, but for steel a good first estimate is to use the materials fatigue strength as allowable. (Fatigue strength is the maximum stress that the material can endure indefinately, so the asymptote in the S-N-curve).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanx, but we needed FS at everypoint of component in analysis for our project.![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If the analysis is linear, just apply a scaling factor of (1/allowable value) in the results window (you might need to have more than one load set to enable this option).

It will give you exactly the same plot, just with the numbers scaled... (I'm not sure quite what additional information this will provide).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

here I am attach my both file part and result

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Respected Jonathan sir,

I am student actually.This is my first part for simulation .so I don't the step how to apply a scaling factor of (1/allowable value) in the results window.so can you tell me step??

Jainam Doshi

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Suppose the allowable stress in your material is 400 MPa. You then show stress using a scaling factor of 1/400. Now let's think about what happens:

If the stress is 200 MPa it will show as 0.5 in the resulting plot.

If the stress is 400 MPa it will show as 1.0

If the stress is 600 MPa it will show as 1.5

So basically your plot shows 1/SF. If you adapt your legend so that the max value is 1, you will see a plot where all the blue bits of your model are very okay, the green bits are okay, the orange bits are borderline okay, and the red bits are not okay (1/SF > 1, or in other words: SF < 1). That sounds pretty useful, and should be what you wanted? ("we needed FS at everypoint of component")

Some disadvantages though:

* you will have to explain to your audience what they see in that plot

* you will get questions about every little red speck in your plot, even when it is due to the way you constrained your model

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

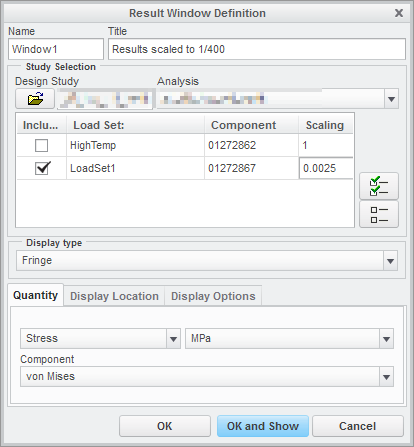

As I suggested, you'll need to have more than one loadset - create another load (doesn't matter what it is; in the image I've used a temperature load) and instead of accepting Loadset 1, create a new loadset.

Then, when creating the result window, you can select either or both loadsets, and enter a scaling factor for each. Per Patrick's examples I've shown this at 1/400 = 0.0025.

My 'HighTemp' loadset is not selected, so will have no effect on the displayed results.

But I don't see why you need to do this - once you've decided what your limiting value is, you can just look at the results and see which areas are above or below this level. If it helps, you could change the legend so that any value above your limit is red - or if you want to see high FOS, you could invert the colours (Format -> Legend) so that high FOS is red and low values are green...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Jainam,

On the simulation of your parts I see that constraints are very high.

I'm wrong can be.

I do not know what is the material on the basis of its forms?

Kind regards.

Denis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

thank you sir.

in this part may force value change.

but with the help of FOS. I want to optimise my part.

Jainam Doshi