Community Tip - New to the community? Learn how to post a question and get help from PTC and industry experts! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: Mirror Body not feature

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Mirror Body not feature

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mirror Body not feature

Hello All,

I am trying to mirror the body I have created but Creo keeps refusing.

Is there a separate function in Creo for mirroring bodies? And where is it please?

If Creo wont mirror bodies can someone explain why this is the case? I cant think why this would be a problem, other CAD packages do it.

As a simple demo, if you create a cuboid then add a fillet to some edges. Then try to mirror the resultant solid. Creo will let you mirror the original cuboid but not with the fillets. I realise for this very simple example you can group the features but this seems a work around and doesn't work on more complex models using surfaces.

If I wanted the cuboid mirroring without the fillet edges I would order the fillets in the tree after the mirror operation.

Thanks for any input.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can either try and group all the operations in the construction tree, then mirror the group... but can lead to some pretty slow regeneration, and modifying/addding stuff will cause you pain down the road.

or you can copy the surfaces, paste them, and then mirror the copied surfaces... faster to regenerate (most of the time).... oh and then solidify the result....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As a general rule, I would avoid mirroring features. When a feature is mirrored (or copied with dependency), the feature references are locked. So, if you need to redefine the sketch and re-dimension it to new references, Creo will no allow it unless you first delete the dependent feature.

Creo also does not support multiple sold bodies in part files as do SW and perhaps other packages. Yes, you can create separate bodies, but Creo doesn't see them as two bodies.

There are two way's you can approach this.

The methods that Corey suggested are how I'd approach this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Depending on the complexity of the model it may be possible to reroute the references for the feature. When rerouting the references you may need to reroute both the original and the mirrored feature. It also depends on the dependency selection, partial or fully; partial won't let you add references but fully will. It may also be faster and easier to just delete the mirror and re-mirror than trying to reroute the features. Changing the dependency type or removing dependency can't be undone. You also want to be aware of selecting mirrored references such as datums. If a new feature is created after a mirror feature where *.prt was selected you may be selecting a mirrored reference which will cause the feature to not be allowed to be moved before the mirror feature until the offending reference is rerouted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks to everyone for the input.

All these methods seem work arounds (to me) if its a simple, solid model, why do I need to start using surfaces to mirror it? I am new to Creo from other CAD packages so still trying to learn. Is Creo more stable using surfaces to model than solids generally? Previously I have always tried to avoid using surfaces where possible as thought they were less stable than solids and usually made the model more complex than it needed to be.

I always thought Mirror, pattern functions etc were encouraged in CAD? Saving operations, reducing repertition ensuring any modifications are carried out throughly etc.

Any idea why does Creo not support multiple bodies?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Based on the file you posted and your initial description it sounds like your selecting just a solidify feature and then mirror? If so, this doesn't work because solidify depends on surface geometry for its definition; this is the reason for the failure, it is asking you to select a surface feature to define the mirror solidify. Probably the reason it works in other CAD packages is the dependencies that are created in CREO are not created in others.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mirroring can be very robust, depending on how you do it. Creo has never supported feature mirroring very well, in my view, but whole part mirroring or surface mirroring are very robust.

Creo was designed around mimicking the physical world. In the physical world, two solids are two parts and a single part is a single solid.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mirror and pattern are not particularly good for CAD. Every so often a situation is really simple and can benefit, but my experience is that eventually something changes that disrupts the mirror situation or the pattern. If it's just an appearance thing, like where bristles are on a tooth brush, or can't change, like holes for mounting a wheel on a hub, then patterns are fine. But with even simple holes and using them as a basis for bolts, eventually someone will add a ground strap so the pattern is not a pattern any more. Most likely it will be the lead hole, so it can't be excluded. Sigh.

Anyway, if you want to mirror a solidify feature, it needs something to solidify. The approach to this is to group all the features required and then mirror the group. Otherwise it is like mirroring the pin stripe on a car when only one-half the car is there. Have to mirror all the pieces.

Solid modeling in Creo is built on surfaces with the software handling the connectivity for the user. Solids are not particularly more or less stable than surfaces, though obviously the farther a process goes the more likely for errors in the lower levels to be noticed.

Creo doesn't support separate parts in a part file. It does support disjoint parts, so that one can make a cut that divides a solid into separate volumes or make disconnected extrusions. It's pretty rare for real parts to be like that - they tend to separate and get lost.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'd have to disagree. In my experience, mirroring and patterning are very powerful for capturing design intent. Yes, intent can change and it can be difficult, but I make good use of both of these tools on a regular basis and have for many years. They work well, within their limitations.

Also, grouping a number of features and mirroring the group is potentially problematic. The group itself limits how those features can be manipulated (although not nearly as much as in the past) and mirroring them locks them further. This makes change much more difficult. You may find yourself having to dismantle a lot in order to change one of the features in that group. The more robust paths forward, all mentioned here, are:

- Mirroring the entire part, if that's what is desired.

- Copying the surfaces that need to be mirrored, mirroring the quilt and solidifying it. The nice thing about this solution is that it is "feature agnostic" if you will, particularly if you can make use of advanced selection techniques like intent surfs and seed and boundary. Even if the copy fails to update, it is usually simple to update.

- Build the symmetry into the features themselves, if possible, by mirroring entities in sketches, etc.

There are many ways to create symmetry in your parts, mirroring the features themselves is the least robust and I'd avoid it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

For holes that are patterned and used with bolts, when someone adds something such as a ground strap pattern can still be used it just won't be a simple reference pattern. You can setup the the pattern so that it uses the base pattern you want to follow and add an offset dimension for the bolts to account for the ground strap and or washers. After creating this pattern you can then edit its definition and change it to a table pattern which should contain columns for the bolt offset and direction references. I've tried this with an axis pattern and it works well. I haven't tried a dimension or direction pattern but would expect it to work the same way. For a pattern leader using flexibility or a simplified rep may be solutions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Usually the ground strap requires a longer bolt.

My experience is that people originating designs love the time they save, but aren't in charge of keeping the design up to date where patterns cost a lot of effort.

Take a big product and change how a patterned feature is dimensioned and then look at what happens to all the references to it. AFAIK, all the referencing items are left disconnected and require redefinition to fix.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's been my experience that people will use dimensioning schemes that aren't appropriate for the type of pattern they want to create, they don't understand how the pattern feature they are creating behaves, or they are just creating an inappropriate pattern type. For the example of the addition of a ground strap to a hole pattern that in and of itself dosen't make a pattern useless. If the ground strap is not located at a pattern leader and you require a longer bolt you can remove the reference to those instances within the pattern. If there are multiple locations you can make use of a point pattern to add longer bolts. If the ground strap is located at the pattern leader you might use a combination of fill, curve, and point patterns.

To me if you are having to re-dimension a patterned feature and it is causing referenced features to become disconnected, you're probably defining the pattern and the features referencing them too early. If patterns are costing you a lot of effort in keeping a design up to date, the base patterns for any reference patterns are not well defined or the pattern methodology desired is not well understood to use reference patterns in my opinion. You need to have a well defined base pattern to understand what's going to happen to those patterns or features referencing them.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You miss that I'm not creating the pattern. It's up to me to fix mistakes, and those mistakes are much much harder to fix when a pattern is involved. Someone makes a guess as to what's appropriate and the pattern locks this guess in much more solidly than required.

Unless it's decorative or non-functional, like vent holes, there's not been any case where I said to myself - "Thank goodness that was a pattern - could not have been handled any other way." Mind that I've used pattern relations to create patterns that are now made easy by point patterns.

Sure, after the requirements for a pattern are completely established, one can use any of a number of approaches to meet those, but if the requirement changes, then it's too late.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I didn't miss that it's not you creating the pattern or that it's up to you to correct the pattern. If you look at my posts again you may find that I'm actually agreeing with you to some extent. What I'm taking issue with is the examples you given so far.

For the example of ground straps, to say that adding one makes a pattern no longer a pattern or makes a pattern useless or difficult to deal with, i don't necessarily agree with that. There are ways to deal with that using patterns that don't necessarily make things more difficult to use or unusable.

For patterns that are taking a lot of effort, to me the feature and/or pattern is not defined well enough or understood and, therefore, the pattern and features and/or patterns referencing the base feature and pattern are probably being created too early. If someone has used an inappropriate pattern type, it can be due to the reasons mentioned before as well as people not thinking about what it is they are really trying to accomplish.

In my opinion, it's not that mirror features or patterns are not good for CAD, it's the modeling practices that people have that can make these features difficult to deal with or unusable not the features in and of themselves.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It sounds like you want to create a part model by modeling just half the part and creating the other half by mirroring.

Forgive me if I'm off the mark. I haven't read all the posts in this thread and I'm not quite sure what a body is.

If this is, in fact, what you are trying to do, it is accomplished quite easily. Although Creo has once again cheated common sense,

by changing/ hiding the basic functions we in the real world daily rely on, I assume with the best of intentions and more of those

imaginary productivity gains as their impetus. /snark/

Here's what you do to mirror all geometry:

- Select the part name at the top of the Model Tree

- Click Model > Mirror

- The Mirror tab appears

- Select a Mirror Plane

- Done.

In the plastics biz we used to use this trick all the time before product developers created their own solid models.

Yes, I'm that old. lol

I've attached your part with the second half mirrored with my possibly incorrect idea and orientation.

Forgive me for not paying attention if I'm off on a tangent and wasting everyone's time.

Anyway, hope this helps

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Gavin,

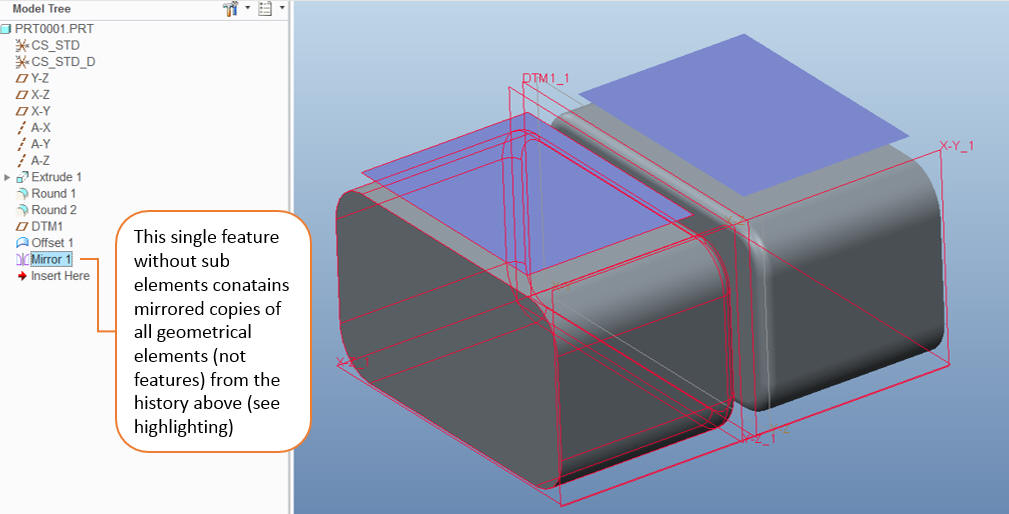

I am not sure what you tried initially. You can mirror the entire solid by selecting to top node in the tree and then select the mirror feature. As a result in the tree you will just see the mirror feature (no sub elements). The geometrical result is a duplication of all geometry created prior to the mirror feature, including quilts and curves.

If this fails it might be due to intersections.

The other two options were discussed above:

- mirror all features - not recommended

- mirror and solidify the solid surface (copy) - highly recommended, since it will NOT mirror datums like the above mentioned.