Community Tip - When posting, your subject should be specific and summarize your question. Here are some additional tips on asking a great question. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Helical Sweep Issue with Accuracy Problem

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Helical Sweep Issue with Accuracy Problem

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Helical Sweep Issue with Accuracy Problem

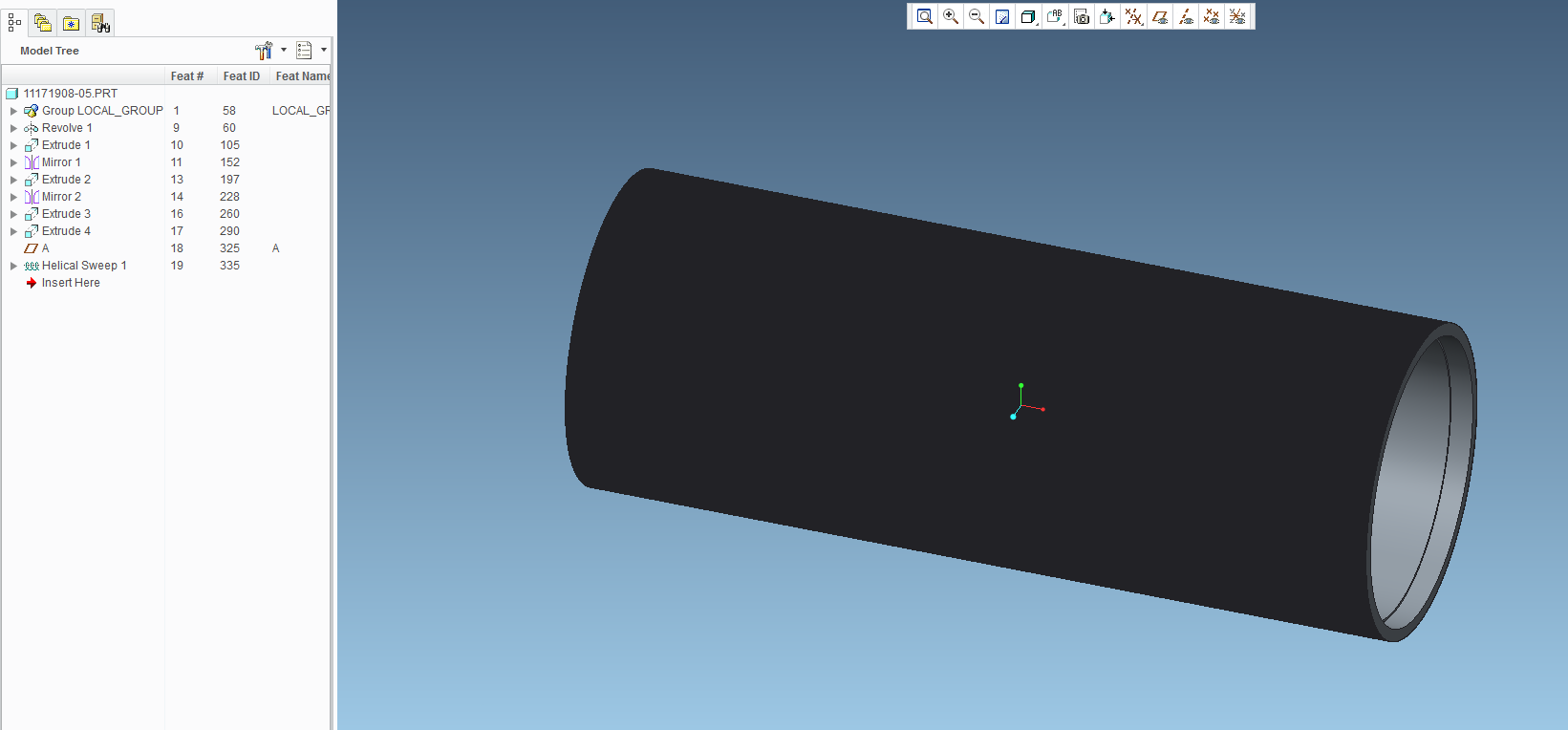

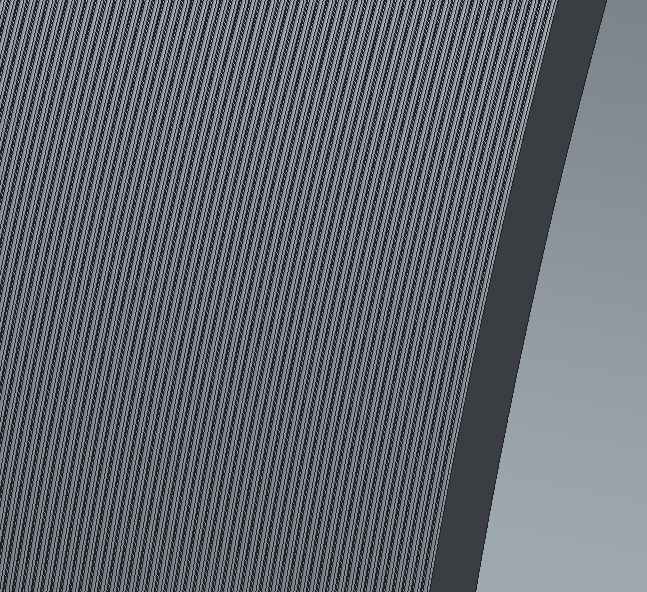

I am trying to create a groove in a roll that I am modeling and I am having issues where the groove is so small that the helical sweep wouldn't regenerate. So, I changed the accuracy of the part to absolute and .0001. The helical sweep will now regenerate, but it takes forever and I can't get the drawing for the assembly this part is in to open. Any suggestions?

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

Assembly Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Three options spring to mind:

- Model the sweep for a small portion of the cylinder and make a note that it should extend the length, then create a detailed view of the that end of the cylinder showing the details of the groove.

- Fake the helical part. Just model it as a revolved cut. Should be much faster to regenerate. Then create the detailed view.

- Model the sweep as surfaces and then use them to make a solid cut. Should also regenerate faster. Still go with a high magnification detailed view to display the details of the groove.

I would not suggest trying to sketch it in the drawing, that is just asking for trouble.

-marc

CAD / PLM Systems Manager

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yeah, don't model the sweep. ![]()

Instead just create a sketch the shows the sweep profile and show this sketch on the drawing in a detail view.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The problem is that the profile of the groove is so small that its not showing up in the drawing after I sketch it in the model. I might just have to sketch it in the drawing for it to work correctly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

With a detailed view you can set the scale completely different from the other views and really "zoom in".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Three options spring to mind:

- Model the sweep for a small portion of the cylinder and make a note that it should extend the length, then create a detailed view of the that end of the cylinder showing the details of the groove.

- Fake the helical part. Just model it as a revolved cut. Should be much faster to regenerate. Then create the detailed view.

- Model the sweep as surfaces and then use them to make a solid cut. Should also regenerate faster. Still go with a high magnification detailed view to display the details of the groove.

I would not suggest trying to sketch it in the drawing, that is just asking for trouble.

-marc

CAD / PLM Systems Manager

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Marc, that worked well with faking the part with a revolved cut.