Community Tip - You can Bookmark boards, posts or articles that you'd like to access again easily! X

- Community

- Creo (Previous to May 2018)

- Creo Modeling Questions

- Re: Optimizing drill bit geometry

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Optimizing drill bit geometry

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Optimizing drill bit geometry

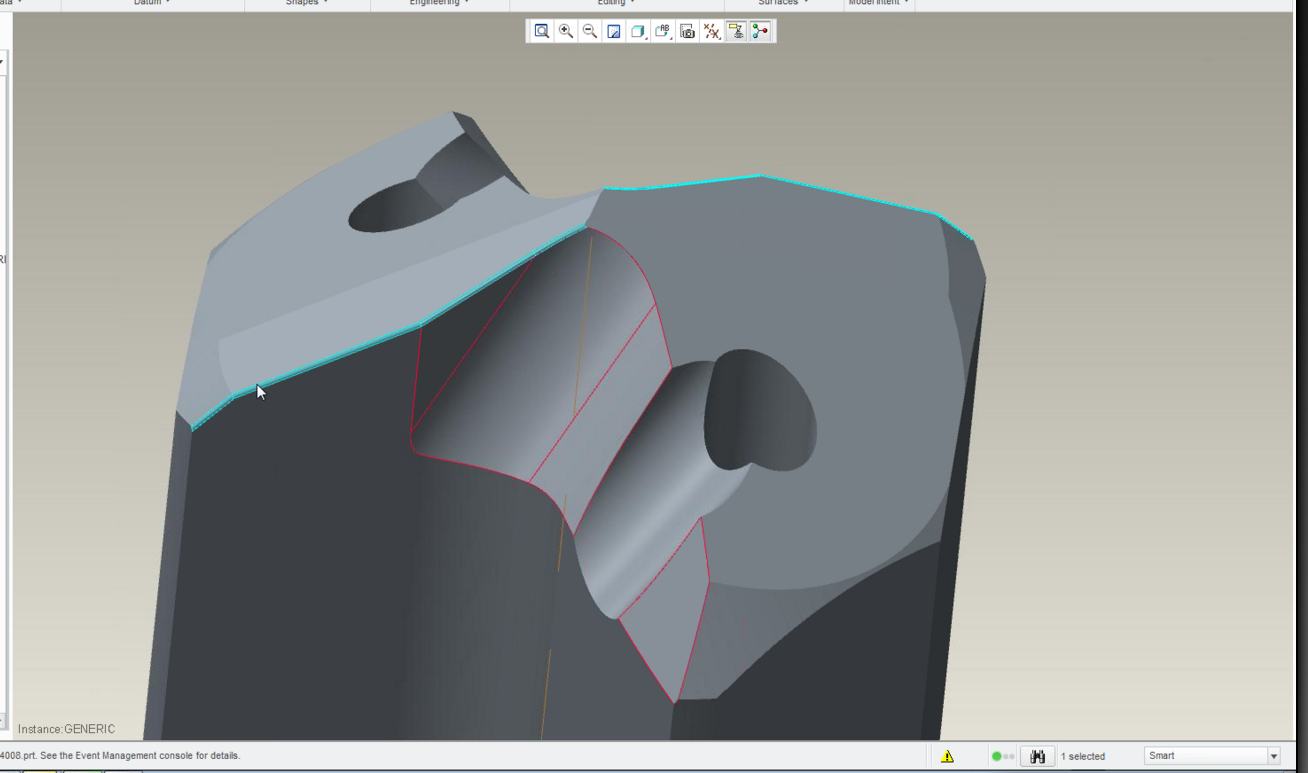

I have a customer asking if Creo can be used to optimize drill bit geometry. What combination of angles for the different edges will give the best performace for a certain material. Attached is an image of his model.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It can be used to MODEL the optimal drill bit geometry, I can;t say it will just automatically DO it. You could create a family table of drill bits, using different geometries for different materials to be cut.

I wolked with a Tooling Engineer once when working on a job for the US Navy where they cut exotic stainless and other alloys. Fascinating stuff, it's a science all unto itself, and this guy KNEW it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Frank, I have research this a bit since my posting .. it is fascinating. I still have no auotimated solution, most seem to be OK with trial and error. I'm from the Mathcad side of PTC and if we had the math models we would optimize, but this is simply geometry, lines and angles, no functions involved.

The search continues. If I find anything I wil post

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's not simply geometry, but a study in how to induce failure in various materials without damaging the tool and without catastrophic failure in the workpiece.

Think of it as understanding the theory of failure of everything subjected to local forces.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Agreed. Simple geometry was refering to the part displayed above.Simple meaning there was no math behind the modeling.

This is such a common application I am a little shocked how little is published on it. Or how little I can find anyways.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Wow, that's heavy, dude...... ![]()