- Community

- IoT & Connectivity

- IoT & Connectivity Tips

- Digital Performance Management is Here!

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Notify Moderator

Digital Performance Management is Here!

The long-awaited manufacturing solution, ThingWorx Digital Performance Management (DPM), has arrived! Announced at PTC’s Manufacturing Live event, DPM provides key use cases around overall equipment effectiveness and real-time performance monitoring, while delivering insights with analytics and automated bottleneck identification tools. DPM gives customers clear insight into where and what to fix to drive efficiencies. Composed of modular building blocks with a foundation on the ThingWorx platform, DPM is easily configurable and customizable for closed-loop problem solving that drives productivity.

Let’s take a deeper look into what DPM is and how you can implement it to ensure your investment in the ThingWorx platform and digital transformation delivers business impact.

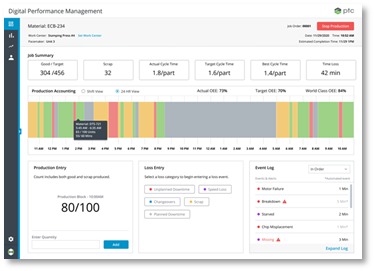

Monitor in real-time with Production Dashboard

The Production Dashboard allows for automated or manual data entry of reason codes with a simple interface for limited disruption. Rather than providing front-line workers with the typical, difficult to understand, percentage based KPIs, Production Dashboard standardizes all losses, so operators can proactively resolve issues during production. You can configure this dashboard to collect granular data and allow opportunities for continuous improvement in process tracking.

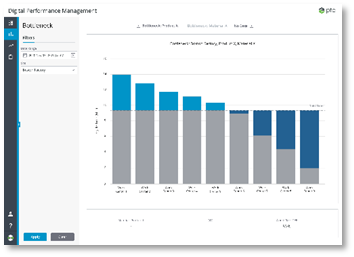

Focus with Bottleneck Analysis

Bottleneck analysis automatically identifies bottlenecks across the manufacturing process. Identifying bottlenecks can help you prioritize the highest-impact opportunities in the business process. This saves you having to manually identify and analyze potential issues and frees you up to work on other projects.

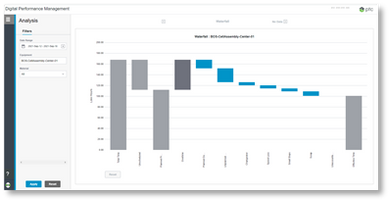

Prioritize with Time Loss Waterfall and Analyze with Loss Reason Pareto

Monitor and analyze performance with data visualizations that help you pinpoint root causes and suggest improvements. Bring together your siloed data into one system and create a standard for how performance is measured and reported.

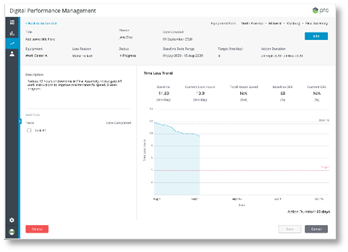

Improve with Action Tracker

Action Tracker allows you to create continuous improvement actions tied to real production losses, to ensure your actions are having positive impact and return. Create a digital workspace for teams to collaborate and learn from each other. Plus, you can track the improvements delivered through each individual action, so you can drill down and create transparency of work being done.

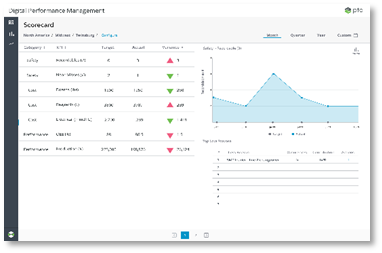

Confirm value delivered with Scorecard (Available in Later Versions)

With the Scorecard feature, you can leverage a standard scorecard for enterprise wide KPIs to summarize factory health and compare similar factory operations. Use the scorecard to create trending and reporting that can be filtered based on the audience you are presenting data to. The scorecard gives you a consistent view that measures performance across the network and drives visibility and accountability across your business.

How do you plan to leverage DPM or the building blocks that make it up? We’d love to hear your thoughts on the first manufacturing solution from PTC.

Stay connected,

Rachel