- Community

- IoT & Connectivity

- IoT & Connectivity Tips

- ThingWorx Apps

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Notify Moderator

ThingWorx Apps

Pre-built apps for manufacturing operations that rapidly deliver value.

Overview

Think Big, Start Small, Scale Fast

Getting started on an industrial IoT project can be daunting, especially deciding where and how to begin. After collecting the experiences gained by working with over 1500 companies on IIoT applications, PTC has made the process to get up and running easier. By grouping IIoT capabilities together in functionally oriented programs, PTC built out-of-the-box applications that rapidly deploy and scale across new or existing system infrastructure. Instead of starting from scratch, you can use ThingWorx ready-to-configure apps to quickly lay the foundation for industrial transformation and implement IIoT solutions in as little as 90 days. ThingWorx Apps offer a comprehensive, basic IIoT scheme to connect to your equipment, collect real-time data, create notification work flows, deliver role based dashboards, and more. Need something more tailored to your operation? No problem. You can iteratively extend and customize ThingWorx Apps into additional use cases for continuous innovation.

Manufacturing Apps

Manufacturers are under constant pressure to minimize downtime, improve quality, and respond faster to individual customer requirements, all while lowering costs. The ThingWorx Manufacturing Apps are pre-built solutions that can be tried in less than 60 minutes without disrupting production. These apps provide manufacturers with real-time visibility into factory floor operations, from individual PLCs to assets to plants to enterprise-wide operations.

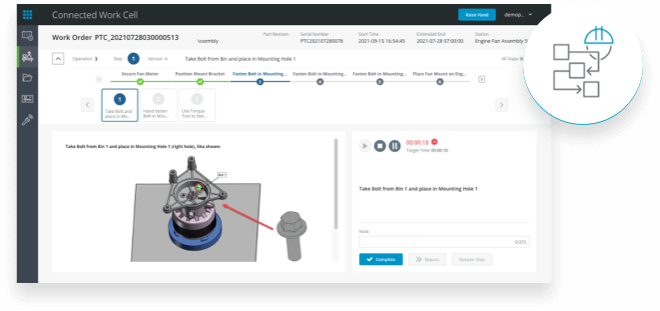

ThingWorx Connected Work Cell

- Lite work instruction authoring with multiple step types and versioning

- Workpiece routes editor and work order scheduling

- Step-by-Step tracking of operator execution

- Smart tool configuration

- Work station dashboard display

- File storage and document management

- Present accurate, up-to-date work instructions using 3D models

- Aggregate work requirements from multiple sources into one simplified display at the work station

- Increase workforce flexibility by reducing upfront training before being assigned to a new work cell

- Improve quality by collecting actual tool use data

- Rapid implementation and fast time to value

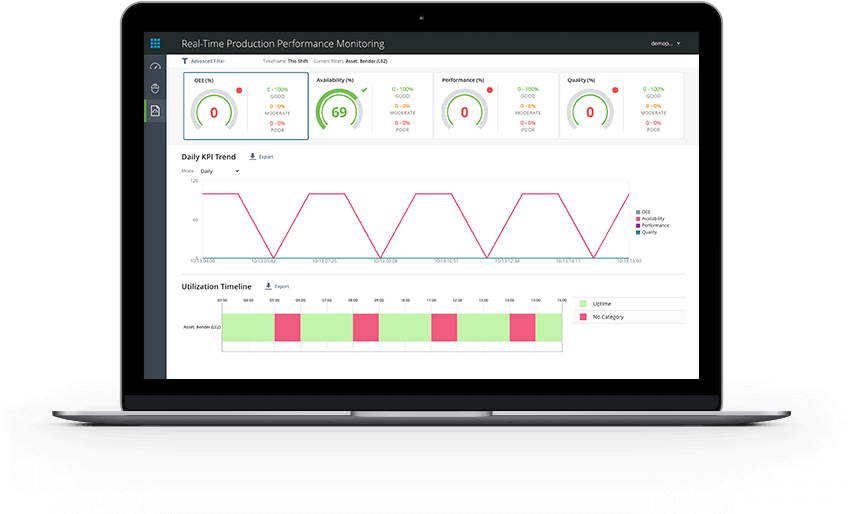

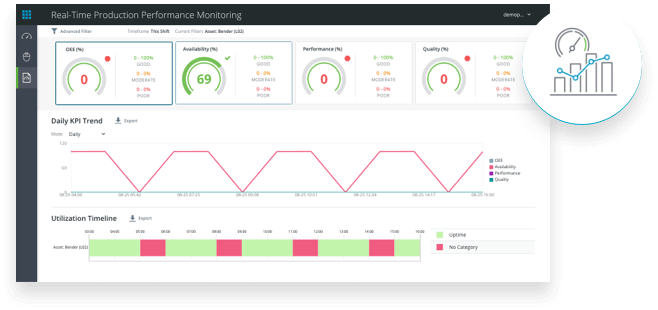

ThingWorx Real-Time Production and Performance Monitoring

- Connect existing assets and gather real-time data

- View overall equipment effectiveness (OEE), mean time between failure (MTBF), and mean time to repair (MTTR) in real-time

- Compare geographically separated assets, lines, or products based on date, time, shift or crew

- Improve operational performance of existing assets by increasing throughput and decreasing waste

- Balance labor vs. capital expenditures to meet production needs

- Determine true overall equipment effectiveness for multiple facilities

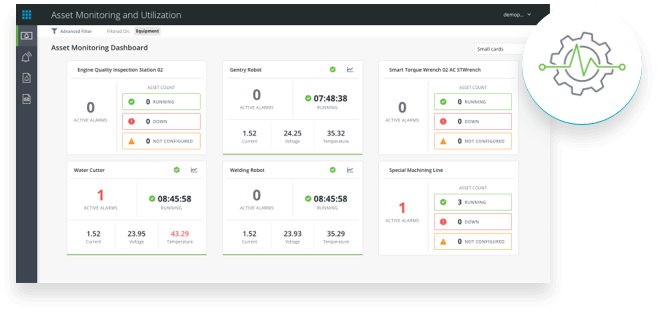

ThingWorx Asset Monitoring and Utilization

- Performance Dashboards with real-time access to open alarms

- Email and SMS distribution rules for messaging and alarm acknowledgment

- Integration to maintenance systems

- Detailed screens showing asset health, configuration parameters, and sensor trends

- Quickly identify anomalous data trends and perform Root Cause Analysis

- Maximize asset uptime and availability with alerts on critical issues before they impact performance

- Rapidly connect to and catalog existing assets

- Quickly Identify Anomalous Data Trends and perform Root Cause Analysis