Community Tip - You can Bookmark boards, posts or articles that you'd like to access again easily! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Toroidal Bend Issue

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Toroidal Bend Issue

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Toroidal Bend Issue

Looking for some assistance after trying what I believe is everything.

I am developing a tire with a finished profile as a flat. Once the tread and details are complete, I am looking to apply the bend. Everything works fine with 1 half of the tread, the bend works. I finish the other side and the bend fails.

Any thoughts?

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't open .rar files as a rule, but why are you not making the full 360 degree bend in one feature?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The RAR is just a compressed archive, the model is over 20MB.

I am doing a 360, as stated above, it works with half the tread (SIDE-A), as soon as the other half is activated(SIDE-B), the bend fails. The results can be found in the file.

Images in attachment - PDF

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Got it. What if you lay the tread first and then the rotated carcass?

Something about boundary blend is like warp where the formed features are copies of the original.

This may be causing a problem. At least, the carcass appears to be the only common element.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is the heart of my confusion.

The base extrusion is the reference surface for both ends of the 360. In fact, I over extruded by a pitch value on both ends, trimmed them back to make sure there was no extraneous geometry to 'upset' the bend.

The fact that it works on 1/2 the tread elements does not help me figure out why the other half fails.

I have had issues in the past where rounds on tread elements make the TB360 fail, and removing those round features resolves the problem mysteriously. It just means more work to place the feature 1-by-1 after the bend, on over 600 elements x corner/edge count /sigh.

However, I made it a point to not even add rounds or drafts to this one before the bend.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

🙂 features such as this always require extra effort.

You can try accuracy and you can see if there happens to be a tangency at the merged ends.

Sounds like you have the bull by the horns. Now you just need to wear it down.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Accuracy is already at the lowest CREO will allow.

I have found that if I reduce the amount of pitches on SIDE-A, I can then add the SIDE-B tread at the same number of pitches. To go beyond that fails the 360 bend.

I have also made the change to be able to suppress SIDE-A and activate SIDE-B, basically reversing the original setup. That works as well, only 1 side will bend.

I have done 1 side as a surface and then solidified, tried all variations, with repeatable results.

I have made both sides surfaces, same results.

In the end, I can have all tread elements activated on a flat, the bend 'breaks' the model if more than 12 pitches of the tread features.

This really looks like a software issue, not a geometry issue. The only way this can be viewed as having the bull by the horns, is if the horn is attached uncomfortably....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is not as unusual as you may think.

A support case would get you a clearer answer for sure.

When I suggested accuracy, I meant crank it up, not down.

And if you bend the entire treat in one go rather than L and R?

I do believe it is the same problem as working with Warped surfaces.

There is something in the underlying definition that makes it a "non-parametric" surface for lack of a better way to consider it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think we are saying the same thing on accuracy 😛

I have opened a support case, even referenced this thread into it.

Thanks for the follow up, I will post any updates here.

In the meantime, I am updating to M050 now, to see if that magically fixes the problem.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Which version of Creo are you using?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

5.0.0.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Definitely worth having PTC look at it 🙂

I'm still running C2 and C3 so I couldn't see it if I wanted.

And yes, I am running these by choice.

Not sure C5 would work in an environment where C2 and C3 need to continue to work properly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

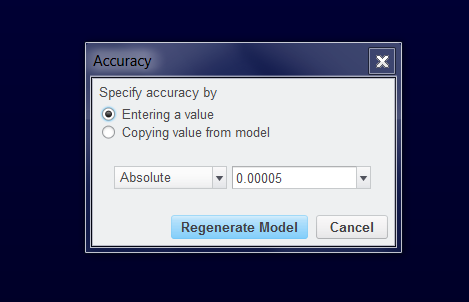

Just to be sure, you also altered the accuracy_lower_bound setting?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the reply pausob.

Yes, that is at the max allowed of 0.0001.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I go here when I have to:

default_abs_accuracy .00005

enable_absolute_accuracy yes

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think I have done one toroidal bend in my career and it happen to be for a tire tread also...more than 20 years ago...so I am of no help there.

But on occasion, accuracy will throw you a curve ball and something will not regenerate with a superfine accuracy and will regenerate with a much coarser accuracy. It only takes a minute or 2 to try a few values and may help.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks, I have tried about 30 accuracy settings, and switched between Relative and Absolute, even though there is no import geometry.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What am I missing about import geometry?

I am assuming that you have tried this with simpler geometry and it works just fine, right?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Relative accuracy should be adequate for any developed part.

Absolute is best suited for when geometry/objects are being imported.

At this point, I am trying everything.

I also verified all intersections would not overlap as a result of the bend by making all surfaces normal to each other on the tread. I have not yet received a response from Support, so I have engaged a resource partner to swat the hive as it were.

I am really starting to believe this is a complexity limitation on the surfaces for CREO. There is a threshold I have to have surpassed that the feature stops working. I have developed dozens of tires with toroidal bends. This is the most complex tread so far with many small elements, relatively. Passenger car tires are far more complex, therefore PTC should be able to address this either from a license level or configuration change.

If the features work up to a point, then license should not be a factor, imo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Funny, that's the first time in 30 years I've heard that 🙂

You do know what default Creo sheet metal (even empty!) also open with absolute accuracy enabled and set, right?

I just had to ask so I didn't have to go and try it.

I do this with physical threads (not treads, threads) and helical sweeps.

They are the most stubborn thing you can do in Creo. There is very little you can make infinitely parametric When it comes to developing these types of threads that require a lot of rounds.

When I need to tweak it, something fails 90% of the time.

However, there are even more occasions when it will not generate the helical sweet at all.

I find myself reordering the entire design just to get the helix to work.

That is definitely not your issue as the process for Toroidal Bend is fairly well defined and straight forward.

So let me give you one other option with your last reply...

What if you reduced the height of your tread (assuming this made it work)... and using "offset" to get the final height? The Offset feature may just help point you to the piece of geometry that is actually failing the full gambit.

I wonder if Toroidal Bend is ever really used for tire tread definition by tire developers.

I could see a massive patterning effort to get there, however.