Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- PLM

- Windchill Discussions

- Functional Description of a part or assembly

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Functional Description of a part or assembly

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Functional Description of a part or assembly

Is it possible to create a functional description of a part or assembly in a model that is carried through to a multi-level BOM that can be exported to an Excel file?

For example; I want to functionally identify a "Right Front Wheel Assembly" as being different from a "Left Rear Wheel Assembly" but they have the same part number.

- Labels:

-

Other

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Graeme,

Please consider the following.

What does it mean ‘the same’ object and ‘the same’ functionality. Having the same four wheels promises a smooth rotation, but not the same functionality – the rear wheels may not be balanced.

BOM usually shows the quantity (four) for the same dependent, and to show the user defined dependency attribute (which one?) is a challenge.

Think about changing the design a little bit – introduce a family table. The generic could have the Description attribute “wheel assembly”, and four instances will have a table-driven Description attribute saying “front left”, “front right”, and so on. You may have even a Color attribute for every wheel. Now change the generic dependent by its instances.

The drawback would be that instances have own part/assembly number and BOM will show them in separate rows.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Konstantin,

Thanks for your response.

The issue is more fundamental than the possibility of the rear wheels being in or out of balance.

If one designs a vehicle that has three wheels the same and one odd one (hypothetical case, because I would not design such a vehicle) it would be nice to be able to automatically extract from the ProE model information as in the “table” below:-

Functional Description Part Name Part Number Quantity

Right Front wheel 15” Wheel Assy WHL15-230 1

Left Front Wheel 15” Wheel Assy WHL15-230 1

Right Rear Wheel 15” Wheel Assy WHL15-230 1

Left Rear Wheel 14” Wheel Assy WHL14-210 1

As far as I have been able to establish from the clever ones (I am not one of those – I aspire to automating the project management process based on the modelled products) in our organisation, ProE will automatically change the contents of the “Functional Description” column to the last entry made in such a column for all the components that have the same Part Number and one ends up with following fairly useless information:-

Functional Description Part Name Part Number Quantity

Right Rear Wheel 15” Wheel Assy WHL15-230 3

Left Rear Wheel 14” Wheel Assy WHL14-210 1

Now, I ask you, which is more useful to the people who have to assemble the vehicle – I would have thought the first.

From the first table one can extract the following information:-

Purchase Dept to buy:-

Part Name Part Number Quantity

15” Wheel Assy WHL15-230 3

14” Wheel Assy WHL14-210 1

Assembly group, assemble vehicle like this:-

Functional Description Part Name Part Number

Right Front wheel 15” Wheel Assy WHL15-230

Left Front Wheel 15” Wheel Assy WHL15-230

Right Rear Wheel 15” Wheel Assy WHL15-230

Left Rear Wheel 14” Wheel Assy WHL14-210

One cannot do that from the second table and some of the design intent is lost. With us, it causes huge problems in delays and errors.

On reflection one only needs to have this kind of identification at any assembly level; parts only need to be named, not functionally described.

This whole issue is not about design technique but about automating the transfer of information or design intent for other purposes such as Product Orientated Project Management, Assembly, Manufacturability, Maintainability etc, etc.

From what I have been able to find out none of the CAD design packages allow one to do what is shown in the first table, maybe you can direct me to somewhere with whom I could address this problem.

Once again, thank you for your response and I look forward to further discussion.

Regards,

Graeme.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Try adding the Functional Description description as a flexible parameter and see if that gives you what you want. This will allow you to create two tables one for purchasing group and one for the assembly group. Here is an illustration of what you would get:

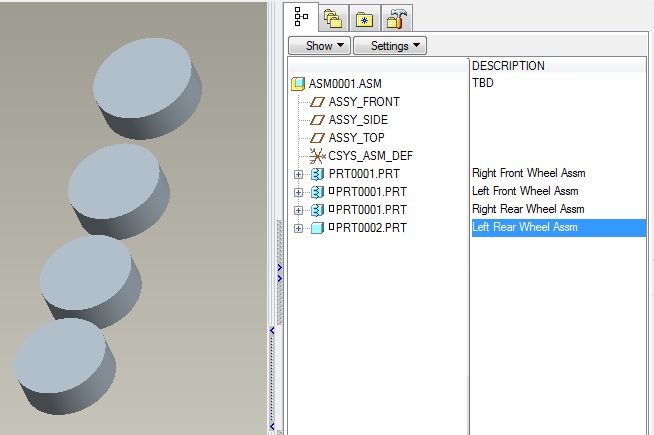

The tables are sorted by the information that is important to the groups. I believe you can export the BOM tables with the same formating shown although I'm not as familiar with how it works. Here is an additional picture illustrating what you would have in an assembly. Although parts are shown the same can be done for assemblies.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Kevin, thanks for your suggestion. I have asked our people who work on this to have a look to see if it is possible and I will let you know what happens.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Kevin,

Thanks very much for your suggestion; it worked a treat and we are going to use the procedure to automate the generation of project plans directly from the Product Structure developed in ProE.

If anybody wishes to find out how we are doing it, contact me.

Regards,

Graeme

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Graeme,

Windchill ProductPoint doesn’t have such functionality.

PDMLink (Windchill) has an ability to customize the BOM adding the user-defined attributes to the relations (or reference designators) and then it can group by them in addition to the part name.

I was trying to find solution using Pro/ENGINEER. It doesn’t work as expected. I do understand the difference between ‘model attribute’ and ‘relation attribute’ (the same model can have different functional descriptions in different assemblies).

I’m sorry if I brought rather confusions than answers.

Regards,

Konstantin.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

HI Konstantin,

Thanks for your input.

As you can see I am going to see if Kevin's suggestion works. Failing that maybe some boffin at PTC can assist.

Regards,

Graeme