Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- PLM

- Windchill Discussions

- What’s New in Windchill 10.0 MPMLink?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

What’s New in Windchill 10.0 MPMLink?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What’s New in Windchill 10.0 MPMLink?

Please read the other articles for this month:

- Enterprise Tip: Reconciliation and eBOM Change Propagation to the mBOM, also by Mike Maylock

- Desktop Product Focus: Creo Parametric FreeStyle, and Tip: Understanding Retrieval Sequence by Tom McNaney

| PTC Technical Specialists Newsletter - October 2011 |

Enterprise Product Focus of the Month : What’s New in Windchill 10.0 MPMLink? |

|---|

Windchill MPMLink Overview

Windchill MPMLink helps resolve the daily challenges that design and manufacturing engineers face in ensuring that process plans, manufacturing bill of materials (mBOMs) and work instructions accurately reflect the current engineering model, and that design decisions consider manufacturing best practices.

Transforming engineering designs into mBOMs and manufacturing processes has typically been a cumbersome process that had to wait until the design was completed. With the digital Manufacturing Process Management (MPM) capabilities of Windchill MPMLink, manufacturers can develop both the product and the manufacturing process definition concurrently, thus enabling you to reduce product cost, improve accuracy of manufacturing deliverables, and shorten development cycle time.

OK, So what’s new in Windchill 10.0 MPMLink?

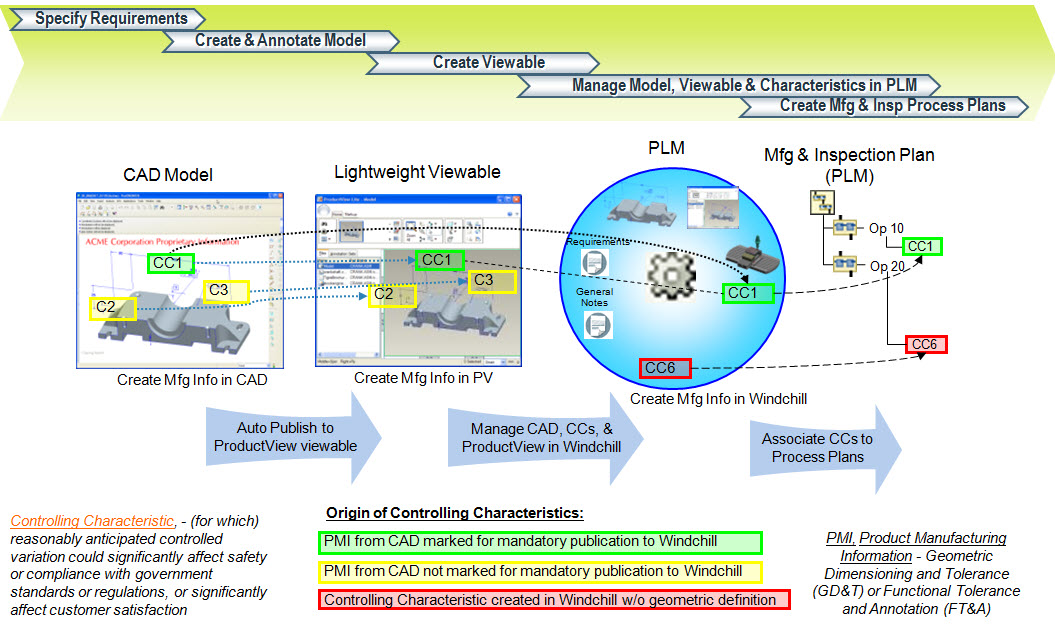

Build quality & inspection plans driven by the definition and management of control characteristics

Expose part machining information to Windchill MPMLink

New in Windchill MPMLink 10.0 is the ability to populate a Part Machining process plan in MPMLink from a Creo NC Manufacturing model. All the user needs to do is associate an MPMLink operation with a Creo NC model, and MPMlink will extract all the steps from the Creo NC models, parameters such as machining time, tooling, resources, comments .. etc .. to populate the operation description in MPMlink and link operation to resources in MPM based on the Creo NC model

Enable process plan reuse by supporting part allocations from multiple assemblies to one Process Plan and Multi-level BOM allocation

Also new in Windchill 10.0 MPMLink is the ability to allow the same Process Plan to be used to manufacture different assemblies, using exactly the same Operations, but consuming different parts from one assembly to another.

In addition, we’ve added the ability to consume parts from phantom assemblies into the process plan of the parent level assembly.

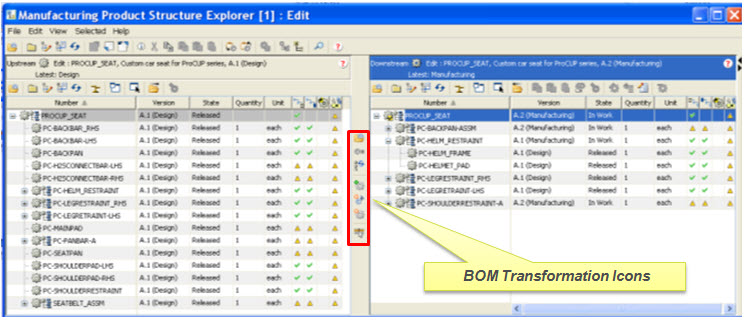

Streamline BOM transformation process with the introduction of a new “dual structure editor” and new “shortcut” actions for most common tasks

In Windchill 10.0, improving the user experience is key. One place where that is evident is in the BOM transformation process. In previous releases, the user was required to go back and forth between 2 windows to perform the transformation. Now, a user is presented with a dual pane window that contains both the upstream and downstream BOMs. From that dual pane window, there is a middle tool bar that allows you to perform a variety of actions between the displayed BOMs. This improvement has typically resulted in a reduction of 50% mouse clicks and 50% mouse travel.

Dual Structure Editor

Reconcile and propagate changes from the eBOM to the mBOM reducing non conformity errors

A new BOM comparison tool is available to quickly identify discrepancies in quantity of items between an eBOM and equivalent mBOM and provide some recommendations to address some of these discrepancies. Discrepancies analysis is done from top down and context by context so that if a part is multi-instantiated in many sub-assemblies, we are able to localize under which ones the issue is in.

Print the Work Instruction for shop-floor users and off-line viewing

A work instruction is a dynamically generated HTML page that combines process plan information (sequences, operation, part allocation, resource allocation, time, etc.) and all related documents such as drawings, images and 3D sessions with annotations.

Work instructions can be used on a manufacturing shop floor as a step by step guide on how to produce, inspect, repair or maintain parts. Because they are dynamically generated any change made to a process plan, operation or sequence is immediately accessible to a shop floor worker, ensuring that the most up-to-date manufacturing information is available at all times.

In Windchill 10.0 MPMLink, enhancements have been added to the ability to print work instructions by adding support for pagination and paper size.

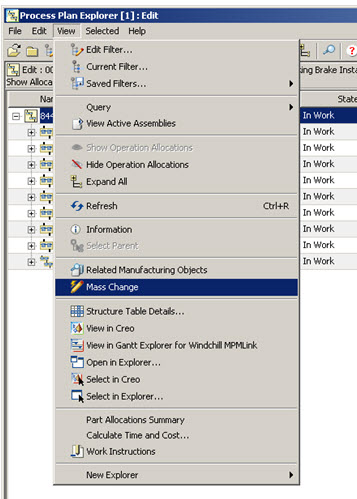

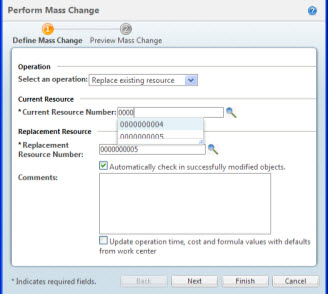

Mass Change support (documents and resources)

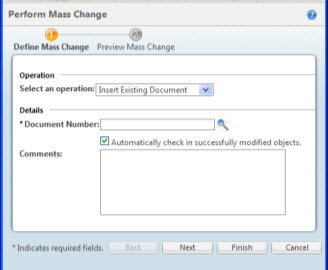

This new and powerful feature allows you to perform a mass replace of allocated resources on operations (processing resources and work centers). In addition, you can perform a mass insert/remove of documents on MPMLink objects.

Mass Change from Process Plan Explorer

Mass Change Wizard

Other serviceability and usability improvements

In addition to the enhancements listed above. Numerous improvements have been made to both serviceability and usability. These include:

- Alternate BOM tab will display all branches of the selected part (preference based)

- Part Equivalent link tab will display all equivalents regardless of equivalent link context (preference based and still config. spec “aware”)

- Part Equivalent link tab will display “out-of-sync” equivalents and identify them accordingly and still config. spec “aware”)

- New action “Operation creation” shortcut action in Process Plan explorer

- Part will be defaulted in BOM Compare panel even if equivalent link is “out-of-sync”

- New preference for automatic check-out (the "Checkout object" check box will by selected by default)

- Remove equivalent links being duplicated upon an “Update equivalent link”

- Support of multiple selections for new branch

- Import/Export Handlers

- Recalculate and maintain occurrence path

- When allocating processing resources to an operation, the system validates that the processing resource is on the same Plant as for the Operation.

- Select in “ProductView for MPMLink” shortcut

- Change indicator now also in all applet

- MPMLink BOM Compare action updated and now considering Part that have been re-used even if there is no equivalent link

- “New Branch” enhanced and creates equivalent links (and duplicate structure)

- Display part and resource allocation directly in process plan structure

- Document propagation from resources to operation upon resource allocation

- MPMLink preferences in preference manager (and regrouped) and what we moved from properties to preferences in the preference manager

- Duplicated operation location now in same location as parent process plan

- New cut and paste of operation (with allocation if under same process plan)

- Keep allocation when duplicating a Process Plan for the same Assembly

- Can create document from the “Document tab”

- Duplicate Process plan and associated part in a single transaction

- Show documents linked to upstream equivalent parts in document tables in MPSE

- MPMLink reports/dashboards in COGNOS

- Labels:

-

Other