Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- PLM

- Windchill Discussions

- Manualnumbering VS Autonumbering

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Manualnumbering VS Autonumbering

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Manualnumbering VS Autonumbering

Hello,

before 6 months we started Windchill 10.2 implemetation. After some time l have some basic problems with parts numbering. Will describe my situation and problems.

Present situation:

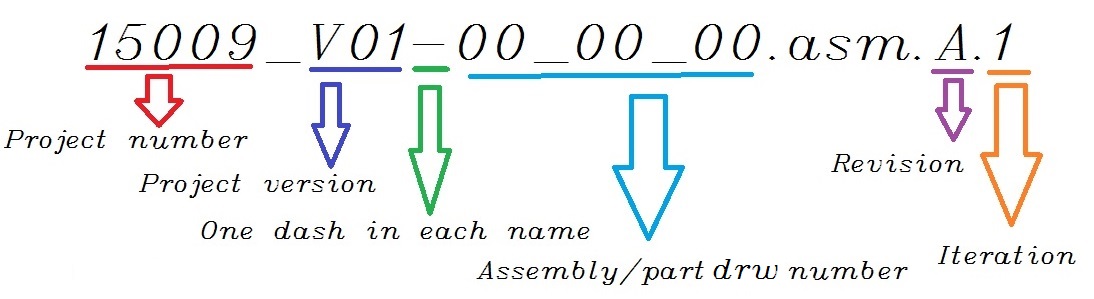

- before Windchill we had use following file name schema:

- each part and assembly includes "extract" function in relation ---> project number and drawing number is included in file name

- 00_00_00 ---> is some logical "model tree" schema ---> example: subassy 01_01_00 includes parts 01_01_01, 01_01_02 ...

- in praxis it means:

assembly moved in model tree ---> rename parts and drawings

- l want keep this logic inside Windchill

Problem:

- during first stage of planing we are changing product structure (model tree) quite often

- Windchill is quite sensitive to rename from the reason of "Drawing - 15009_v01-05_02_05_00.drw is not unique."

- SAVE AS copies does same problem sometimes

My ideas and solution:

- Do l need model number? ---> NO, because all informations are included in file name

- ignore model number ---> turn it to AUTONUMBERING

- will Autonumbering help me? Model number is only for Windchill internal functions, but l´m interested only in file name.

My unskilled imagine about autonumbering:

- Windchill will change model numbers automaticly ---> it will never occur "Drawing - xx_yy_zz.drw is not unique" or am l looking thrue pink glasses? ![]()

Thx for any help or tips...

Solved! Go to Solution.

- Labels:

-

Project_Program Mgmt

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dobry den Milan, Jak se mas?

I am glad the discussion is giving you some inspiration. It is always best when solution is found by oneself than given by somebody else.

I like that you are actively challenging the way you currently work and that you have found by yourself limitation of your current manual systems. If you digg in further you will find plenty others. I am a strong advocate of random numbering ![]()

The reason you have just provided (when reusing a part (component or assembly) into another sub assembly your numbering scheme fall apart.

I guess you have two choices

1) Move into sequential numbering and use the system functionalities to find the information what was once in the filename

2) Persist with your numbering scheme. Renumbering could actually be quite easy. Export the filename into excel, apply some rules in excel to change the filename quickly and use a script to read the new filename and rename in PDMLink.

In the past, I have had to rename thousands of objects (WTpart, NUMBER and NAME, EPMDocument and CAD files, Number, Name and filename). I had a script developed for me. It read a csv file which contains the object number, new number, new name (new filename).

Renaming in PDMLink can be very easy, The difficulty is to find what the new names should be.

ProjectLink is a project management system, You can use it for all sort of projects.

So for instance, if your projects (new product development) usually follow a similar structure (project plan, project team etc..) you can create a project template.

Everytime you have a new project, you create a project from the template. Each project has a unique number,, (up to you to decide what to do with that number, should the project number also be the product number.... ?) You will manage the project plan, the activities, resources , costs (to a certain extend), all your documentation be it Office files or CAD etc... So everything related to the project will be in once unique place, the Project object in ProjectLink. If certain data is shared between projects or PDM, no problem you can share them easily, so people do not have to go and search for them.

I think you should spend more time with you PTC partner. Who are you using in Czech Republic ? Cogras ?

Do you have access to Precision LMS from ptc ? This is a great place to get basic knowledge of functionalities of Windchill and Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

be carefull but for CAD Documents , the file name have to be also unique ... like the number. you will have the same error message

And Windchill is clearly a tool where trying to manage "structure" or "tree" informations in the number (or file name) will lead do expensive management and workarounds ....

what about using the autonumbering for number + filename. And handle other meaningfull informations as attributes ? and let Windchill manage the structure "dynamically" with links ....

regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Without Windchill has to be each file name unique also.

With Windchill l have no problem to keep file name unique. If the message occur simply rename file name in workspace and check-in.

l like the idea, that drawing name is filtered from file name ---> l don´t have to worry about correct drawing number, beacuas it´s automaticly filtered from file name.

----------------------

"what about using the autonumbering for number + filename. And handle other meaningfull informations as attributes ?" ---> file name isn´t acceptable from reasons described above.

----------------------

"and let Windchill manage the structure "dynamically" with links" ---> don´t understand. Could you send me ProE help link or PTC community link to study more informations please?

Thanks you...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

by "dynamically" , I just want to say that Windchill CAD structures are only "links" to childs parts. whatever are their number/filename/name

by having structure/level infomation in the filename ... you will habe to rename each time you change the structure ...

Having meaningfull numbering always lead to painfull BOM and Part management... but adding some structure information in the file name is just another big constraint ...

just my thought ![]()

you probably have business constraints for doin like that

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It was so beautyfull, peacefull and simply word without Windchill ![]() .

.

---------------

"by having structure/level infomation in the filename ... you will habe to rename each time you change the structure ..." ---> l agrre with you. NUMBER autonumbering will make my work half simplify ---> l have to care only about FILE NAME

l have no limitation for new schema / company standards l can do what l want. Only limitation are my own knowledges, that are not good in Windchill and CAD administration area. Don´t know any other system in model, file name or number and l have to choose something... could you give me some tips in generall? Links are enough...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I wish I could turn autonumbering on! I have similar numbering schema - they call it "intelligent", but it is anything but intelligent. We are going through numerous renaming activities when we need to release documents. So, my suggestion is to save time and aggravation in the future, turn autonumbering on.

My $.02

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes!

It´s is really frustating to search what iteration was named the same number sometimes in the past.

The most annoying thing is when following happen:

1. Drawing - 15009_v01-05_02_05_00.drw is not unique. ---> have to check this drw and l discovered, that NUMBER isn´t same like FILE_NAME ---> try to change NUMBER, but the new one also isn´t unique

2. Have to check why new number isn´t unique

3. Discovered, that drawing - 15009_v01-99_99_99_00 is in coflict, because sometimes in the past was RENAMED or SAVE AS wrong way

4. Try to change NUMBER of drawing - 15009_v01-99_99_99_00 and point 1. repeat again for this DRW

RESULT:

l´m going deeper and deeper, looking for fisrt DRW, that l can change. Than l solve it from bottom to up...

Annoying...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Annoying yes . But not because of windchill 😉 because of your structured numbering schema.

An enterprise PLM system like Windchill . or at least if only used as a PDM CAD vault container should help you to not manage this ....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It looks like l need more theoretical informations.

Already ordered http://www.amazon.com/Engineering-Documentation-Control-Handbook-Edition/dp/1455778605

Hope it will be good choice for me... (long delivery time ![]() )

)

-----------

"...should help you to not manage this ...." ---> if l understand correct, you are saing:

1. NUMBER --- autonumbering

2. FILE NAME --- autonumbering? But inside Creo will be model tree full of parts with notsaing numbers (if l´m looking at the problem in some conections)

3. parameter DRW_NUMBER set manualy ---> designate it for WCH ---> attribute DRW_NUMBER

4. parameter PROJECT_NUMBER set manualy ---> designate it for WCH ---> attribute PROJECT_NUMBER

In generall point 3 and 4 destroy the core of company file naming system, that l have build without WCH during last 4 years.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes for a more easy management :

-Set NUMBER=FILENAME

- Set autonumbering . In Windchill , auto numbering does not say necessary non meaningfull numerotation. You can set your own sequence or logic in Init rules

- Use NAME for short description like "nut" , bolt etc ...

-In Creo, you can add for example column "Name " in addition to filename

- and nice : manage creo template parts in Windchill . to be able to use the "new fro workspace" and not anymore the "new" in Creo

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello

Very interesting topic.

In my previous company we had over 70 different numbering schemes (some were sequential numbers but mostly were speaking/descriptive/intelligent number) for managing our product families. And this was without counting what the tooling department did with their numbering scheme.

History is heavy to carry and all those descriptive numbering scheme were invented in a time where people could only rely on manual and paper system. As they moved to computerized system, they tend to keep the same way of working and suddenly problems occurs.

The additional problem I had in my company was that all those numbering schemes were managed by different sites which did not share databases. Implementing a group PDM meant that we were going to have to deal with duplicated partnumber for actually different parts.

Also, relying on descriptive partnumber for sorting, searching and reporting on data is limited compared to using the proper functionalities available such as Part Classification or Soft type attributes.

Trying to use both (ie keep the descriptive numbering scheme and attributes) add inefficiency as it duplicates the information (once in the number, once in the attribute) and this can create conflict (ie partnumber says it is white but attribute says it is black. What is correct ? ) The principle of one single source of information should apply.

This said, I had to take the hard decision in my company (who also wanted to acquire companies) was to come up with a new numbering scheme which was generating numbers automatically, could not conflict with any existing or future ones (such as with acquisition, or some we missed in our inventory), be easy to remember etc…. So we had a solution. It was not accepted first as it required to renumbered some of the existing parts.

Also I liked to call a sped a sped and the model was as followed

CAD Number (EPMDocument) = CAD Filename+ext = WTpart Number = ERP Partnumber

CAD Name = WTpart Name = ERP Part name

Here again, there was non acceptance at the beginning but after 8 years, “everyone” agreed it was the best things to do as we have simplified the situation greatly, no conflicts, easy of identification, integration etc…

Also in the process, (due to a “mistake”, the SAP implementation did not talk to the PLM team and went on with the wrong partnumbers in SAP), we had to renumbered over 100 000 wtpart in PDMLink. This meant renumbering the WTPart, the CAD filename, EPMDocument number. Our reseller developed for us a script. We had family table, data shared in projects, relationship such as used in, referenced by, inheritance etc…. We did a fullscale testing. It took about 7hours to renumber everything. So PDMLink and Oracle (we were using Oracle) are fully capable of digesting file rename.

My suggestion to you is keep it simple avoid redundancy. In your current partnumber you include version. Windchill does that for you.

Why is filename important to you ? I can only see that it is important in Creo when the file is opened in the session and you want to swap between files or windows. However, you have preview. Otherwise in PDMLink and in the workspace NUMBER, NAME and other attributes are always available.

You have project numbers ? Why do you need project number in the filename ? Surely the file will be associated within Windchill to a project or product context, but surely this can be driven by an attribute. Not sure of the use of a project version ? is Project a product for you ?

Anyhow.

Based on my experience and that my new company has the same issues than my previous one and somehow yours, I will do the same again. Moved into sequential meaningless number and have

CAD Number (EPMDocument) = CAD Filename+ext = WTpart Number = ERP Partnumber

CAD Name = WTpart Name = ERP Part name

So partnumbering is no longer an administrative task for the users

If you search the forum you will find many discussion about numbering scheme. Modern systems such as Windchill but also Teamcenter, Enovia etc… have no problem with meaningless numbers while still providing powerful capabilities for searching, reporting, etc… The biggest problem is actually not the technology but the people who do not want to change and therefore miss a big opportunity to become better.

It is like driving a car. You do not drive a car built at the beginning of the 1900s as you drive a car today. If you tried you will stay in second gear and complain the engine is a lot noisier than the old timer ![]()

Good luck with educating your people. This is the biggest challenge in PLM and Knowledge Work Management System implementation

Best regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for input Chris C.

l have read many topics about numbering on this forum, than a told me: "Why am l using manual numbering, when number is meaningless for me?"

l have no problem to propagate any system in our company, the problem is: "Which one or what shall l choose?"

l´m open to any system, that will be the most simply and functional.

For me is product and project the same.

Company CAD data management history without Windchill:

- company estabilished without any idea how to use ProEngineer (l´m the first employee)

- l think ORDER HAS TO BE ---> we choosed a file name schema 13009_V01-00_00_00

- 13 --- year of project begin

- 009 --- project number in this year

- V01 --- version of project (we have many similar geometries)

- "-" --- only one dash in each file name (dash is a relation separator)

- 00_00_00 --- part or assembly drawing number

- parts and assemblies included following relations:

IF CISLO_VYK_V_NAZVU==YES

typ_oznaceni=EXTRACT(REL_MODEL_NAME,1,SEARCH(EXTRACT(REL_MODEL_NAME,1,(\STRING_LENGTH(REL_MODEL_NAME))),"-")-1)

cislo_vyk=EXTRACT(REL_MODEL_NAME,(SEARCH(REL_MODEL_NAME,"-")+1),((\STRING_LENGTH(REL_MODEL_NAME))-(SEARCH(REL_MODEL_NAME,"-")+1)+1))

ENDIF

Explanation:

- CISLO_VYK_V_NAZVU (english translate: DRW_NUMBER_IN_MODEL NAME) --- if set to NO, than the connection between file name is broken

- typ_oznaceni (english translate: project or product) ---> result: 13009_V01

- cislo_vyk (english translate: drawing_number) ---> result: 00_00_00

- it had worked great upto Windchill implementation

- it tooks me so much time to make so many decisions and inovations in this area without WCH, that l want to keep it (is it mystake or pink glasses?)

- l discovered this schema in some project from the year 1960. But als you said: "It is a time to inovation and start to think different way with WCH or any other datab management program. Simply because it is 21st century." l have no problem with this.

Company CAD data management with Windchill: (describes my imagination ---> l have pink and unskilled Windchill glasses ![]() )

)

- l wanna keep this schema ---> from your inputs l have started think if it is a good choice?

- l have to choose something better from the reasons described above

Informations from our Czech PTC technology provider:

- we recommended manual numbering

Company knowledge and skill:

- 1 engineer (me) - 5/10 Creo expiriences; 1/10 Windchill expiriences; 1/10 CAD data management; 8/10 data management (folder structure)

- 2 business persons - 0/10 Creo expiriences; 0/10 Windchill expiriences; 0/10 CAD data management; 8/10 data management (folder structure)

Future:

- engieering team will grow upto 10 people

- need some concrete and simply work system

- in upcomming 1 month we will order a WCH customer suited user training by our Czech PTC technology provider and l need some ideas for discussion. How to do that and that, why we can´t do it like this? etc... This topic will be one of my arguments for upcomming changes.

Thanks for any tips from your praxis...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dobry den Milan,

It is always frustrating to feeling that what has required great effort to set up and was very successful in the past must be “undone”/modify because of adopting new technology. Obviously it does not have to be but there is a BIG risk to then underuse the new technology.

I am very disappointed by the PTC consultant comment. It seems that he or she took a shortcut and the easiest option for him. On the other hand, trying to program Windchill to reproduce this numbering scheme is surely a challenge and therefore leave the field as a manual entry seems a reasonable option. However, adoption new technology is not about fitting the old of way of working into the new technology. It is an interactive process. It is important to understand the capability of the new technology (and from your skills scale you have kindly and honestly provided I can see some big gaps). This can be compensated by working with a consultant and going on training, forum, meeting other experienced people. There is no One Solution fits all but there are some principles for every implementation.

Understand your business process

Understand the technology and what it brings

Revisit/re engineer your business process to make the most of the technology.

My approach would be to look at what information is carried by the filename. Does that information exist else where, If so, is it generated automatically or not

Aim for no duplication of the information

Can you see tools in Windchill such as searching, reporting, filtering that will work better using Out Of The Box functionalities of Windchill (Such as location or Attributes) than trying the same with filename. How can you report on filename eg. How can you quickly with Windchill find how many revisions of the same projects, Number of project generated in last 6 months, project still open (uncompleted) number of finished projects, which one are late, who is working on which project etc….

You will see that the information in filename should be irrelevant as you will get all that information from elsewhere.

Also do not forget that you are setting up a system not for you or the existing users but for the future. You will soon have new people who will have no experience in your complex numbering scheme. Do you want them to spend time learning and generating manually number or spend time learning about your product and dealing with your customer. Where is the added value of your engineers ? In creating numbers or dealing with customer’s requests (generating new ideas, providing good advice to your customer etc…)

Partnumbering is only one aspect and on the same register there is about document management, process and the flow of work to manage. Have you identified the value stream of each project. Do you have a repeatable stream for each project ?

Your PTC partner should be the one helping you identifying all this and ensure you do not only install a new software but actually implement a new technology that will make you more efficient, more productive and give you competitive advantage.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for comments.

- l think you guess it right. We have only instaled Windchill not really implemented yet.

l will describe reasons why l want keep this schema:

File name is carried product (project) number and drawing number:

- product number - 2 different products have the same TOP assembly drawing number (00_00_00), looks relevant to keep product number in filename to make files unique (can also add to context inside windchill)

- drawing number - seem to be usefull due to extract relation (described above)

Searching inside Windchill:

- searching by:

- whole file name ---> idetify 1 part ---> OK for me

- drawing number in pruduct level ---> identify 1 file (15099_V01-00_00_00) ---> OK for me

- drawing number in database level ---> identify (15099_V01-00_00_00; 15011_V01-00_00_00...) ---> OK for me

Information duplication:

- drawing number

- filtered from file name ---> don´t have to fill parameter or atribute again. Just call the value from file name. Note: l don´t know any other automatic method for this.

- filtering from name ---> using SAVE AS copy ---> name isn´t unique ---> same drawing number already exist for this prudoct ---> can´t exist 2 same drawing number --->will change file name 1 number up ---> "is it kind of automatic control or am l thinking bad about this functionality?"

- for better ilustration see picture bellow:

- manufactured parts are small letters ---> user input

- buying parts are large letters ---> automaticly filtered from file name

- size of letters gives me quick review about buying and manufactured parts

About workflow:

- still hasn´t been set any ---> it´s bad situation ---> it is under construction ![]()

- we are constructing single-use machines ---> each piece is a prototype ---> but the workflow looks similar for each machine ---> looking from point of view: CAD data management, busniss management and manufacturing. Should l think about some other aspect?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dobry den Milan

it seems that you are very happy with this manual numbering scheme. Beyond state of the art system and functionality, user acceptance is key.

So better have happy users with a less efficient system (my view ) than the most efficient system no one wants to use.

It is your call how you guys want to use Windchill and therefore if there is no wish to change the PTC consultant was right. Do not customize Windchill to automatically generate such numbers, keep it a manual entry.

From your last point. Have you consider project management. Do you have projectlink ?

Good luck with your implementation and have a nice weekend

Best regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

l was happy with this uptu this conversation, you are changing my opinion.

Right now during a work l need to move subassembly 15009_V01-05_01_00 to another subassembly 15009_V01-09_00_00 ---> all parts that are included have to be renamed ( in order to keep our logical file name schema) ----> it´s lost of time. Looking for ideas how to change whole company system.

----------

It´s really good question about Projectlink, but l feel a little embarassed. Have no idea how and for what use it? Have to search more information and than will come back to discusion.

-----

Study, study,study...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dobry den Milan, Jak se mas?

I am glad the discussion is giving you some inspiration. It is always best when solution is found by oneself than given by somebody else.

I like that you are actively challenging the way you currently work and that you have found by yourself limitation of your current manual systems. If you digg in further you will find plenty others. I am a strong advocate of random numbering ![]()

The reason you have just provided (when reusing a part (component or assembly) into another sub assembly your numbering scheme fall apart.

I guess you have two choices

1) Move into sequential numbering and use the system functionalities to find the information what was once in the filename

2) Persist with your numbering scheme. Renumbering could actually be quite easy. Export the filename into excel, apply some rules in excel to change the filename quickly and use a script to read the new filename and rename in PDMLink.

In the past, I have had to rename thousands of objects (WTpart, NUMBER and NAME, EPMDocument and CAD files, Number, Name and filename). I had a script developed for me. It read a csv file which contains the object number, new number, new name (new filename).

Renaming in PDMLink can be very easy, The difficulty is to find what the new names should be.

ProjectLink is a project management system, You can use it for all sort of projects.

So for instance, if your projects (new product development) usually follow a similar structure (project plan, project team etc..) you can create a project template.

Everytime you have a new project, you create a project from the template. Each project has a unique number,, (up to you to decide what to do with that number, should the project number also be the product number.... ?) You will manage the project plan, the activities, resources , costs (to a certain extend), all your documentation be it Office files or CAD etc... So everything related to the project will be in once unique place, the Project object in ProjectLink. If certain data is shared between projects or PDM, no problem you can share them easily, so people do not have to go and search for them.

I think you should spend more time with you PTC partner. Who are you using in Czech Republic ? Cogras ?

Do you have access to Precision LMS from ptc ? This is a great place to get basic knowledge of functionalities of Windchill and Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Some intersting ideas:

- Once you are using a PDM system, you need to change some old habits. One is using dummy part names an then renaming.

- Otherwise, just ignore the number - it´s only used in Windchill. ![]()

- Your part number should also be the same as your drawing number.

Hope l can share a link to other CAD forum:

http://www.mechanicaldesignforum.com/showthread.php?2600-Part-Numbering-and-configuration-management

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

OK, děkuji Chris C and Gregory Perasso.

You pushed me forward and my brain is burning. ![]()

Now l think about "inteligent" or "non-inteligent" autonumbering.

-----

This topic gives me some directions which l can go.

Perhaps will start some other topics with similar (more advanced) concrete problems.

-----

In future you are welcome in all my topics.

Mark your input as a right answered to close these topic...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dobry Den Milan

you are more than welcome. I just realized that my last message was empty, not sure what happened there. Surely a user's issue

you wrote:

Some intersting ideas:

- Once you are using a PDM system, you need to change some old habits. One is using dummy part names an then renaming.

Why renaming ? if you start from a template you are prompted to give a name a with a brand new object. Unless you mean that the template as a default name that you need to replace ??

- Otherwise, just ignore the number - it´s only used in Windchill.

This is an approach but this would not be using the tool correctly. Best practice is that PDM Number = ERP Number for instance, so better start with good practice to avoid having to renumber in the future.

As far as I and the PLM Think Tank I work with are concerned, things are/should be kept simple

WTPart Number = EPMDocument Number = ERP Number = CAD filename.ext

WTpart Name = EPMDocument Name = ERP Name/description

- Your part number should also be the same as your drawing number.

Here again, I do not consider this has good practice, If you take PDMLink

A model and a drawing are both EPMDocument and OOTB the system will not let you have both number, Even if you could, what do you do when you have 2 drawings for the same model ?

Your part/product is represented by the WTPart, so at a minimum the wtpart should have the same number than your item in ERP.

You could have your EPMDocument for the model have a different number but for what reason , really ? Then come your 2D representation. I purposely call it 2D representation and not 2D drawing as at the end of the day a 2D drawing is only a representation of your 3D model for a given purpose. You could have a need for several representations of your 3D model in 2D. So then how can you give the representations all the same number ?

I have followed the link you provided. I am glad to see that you do not content yourself with this forum only.

There are effectively two schools those who believe speaking/smart/talking/descriptive numbering scheme is the best and the other school which believe that only random/meaningless/sequential numbering scheme is the only good way.

My experience has showed me that generally those in favour of speaking numbers are engineers with a lot of experience in what they do and little in computer system and therefore want to use the system with the "old" way of working.

As Gregory said, Windchill is highly configurable so your number could be automatically generated by the system following rules that create a speaking number. However, you have discovered by yourself the limitation. This speaking number then means nothing when reuse in a different structure....

It is very hard to afford time and money to properly investigate and test all the pros and cons. The good news is that you can have an lean approach of the implementation and consider that your system will be going through a continuous improvement phase for many years. In addition Windchill is very flexible. As a consequence, you could start using Windchill and let your user manually allocate the numbers. You should not delay "too" much an implementation just because of a numbering scheme. Once you start using Windchill and getting other benefits and users more familiar with it, you can revise the numbering scheme. I have in the past had to renumbered teens of thousands of WTpart, EPMDocument and filename. OK we tested it and prepared for it but it only took a few hours to do. The biggest problem was actually that some drawings were not calling the correct parameters for the Number, so when we made the change, it was not apparent on the drawing so we needed to include an iteration of the drawings to replace the parameter.

All this to say that there is no right or wrong way to go live. Go Live and you can always improve and make changes later. One thing though, whatever is decided for go live must be justifiable otherwise it will be said that it was a bad implementation etc.. When things start to go wrong month after go live, users are quick to blame the system or the implementor.

once again. All the best in your journey to perfection

Maji dobry den

Best regards from Havlíčkův Brod