Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Alluminion profiles and family table

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Aluminum profiles and family table

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Aluminum profiles and family table

Hello everyone!

In my company we have recently introduced Windchill and Creo 8 for our little mechanical office. We make machines based on Robotunits Modular Automation System, that means we use aluminum extruded profiles.

Whats the best manner to manage this profiles? The minimum lenghth is 50mm and the max is 6m.

We can use all measure between this min and max.

I thought we can manage this with a family table where I let change only the length of the profile. But this means a table with 6000rows (one each mm).

I don't thik it's the best practice.

So I see on PTC support articles that it is raccomended (with the utilize of Windchill) a max numer of istances of 50.

It's not so simple manage 6000 different length of profiles with 6000/50=120 family table..

What can I do?

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have many family tables in Windchill for hardware items, mostly bolts and screws, were there are more than 50 instances in the family tables.

I know of at least 1 family table that I have that has over 1000 instances in it.

I do not use nested family tables.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Do you plan to use the AFX extension for these designs using the extrusions? That may affect how to deal with this issue. There are some BOM management functions within AFX

Why do you need a model for each increment from min to max values? I would consider creating a model for each extrusion profile of an arbitrary length and use this as a start part for any part suing that profile. If you were to define a numbering scheme that included the profile and length you could then add the unique parts to the vault as they are created for designs. Eventually you would end up with all lengths built.

The part names could look something like this:

extrusion_profile_A_length_50mm

If you do not need a unique part # for each incremental length, you could just create a library of profiles. This library of profiles would be used to make any length part as required.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @GiFra_Label

I see 2 possible approaches.

The easiest one would be to have only one CAD Document (the extrude 50 mm). And then place it in assemblies using the notion of Flexibility (if you're not familiar on this technique, you'll find guidace in article 28948 and help Center here).

If we were only speaking about Creo Parametric I would stop here. But as you mentioned Windchill, the real question you have to answer is as follows: Do I accept to have a unique WTPart reference for my models in my BOMs?

- If answer is yes, you can definitely go with Flexibility as this is for sure the easiest way to reach what you're expecting, and the lowest in term of effort for the configuration and the maintenance process (Visualization tab of WTPart/CAD Document structures is able to handle flexibilities in latest Windchill versions => See article 111791)

- if answer is no ... meaning you want ONE WTPart for each CAD Document at a given length ... No other choice then to use Family tables (or standalone objects)

=> If you go this way, I would suggest Nested Family Tables (first level: the meters, second level: the decimeters (per meter), thrid level: centimers (per decimeter / per meter) to easier the selection of the wished component upon assembly action.

- If you're not familiar on the notion of "nested family tables", just consider that they are faùily table where instances (first level, the meters 0,1,2,3,4,5,6) are generic of other instances (second level where you'll drive the centimeters). In other words: Family Tables of Family Tables

- If you go this way, guidance in articles 220794 & 228089 will help to think about a good autoassociation technique to WTParts in Windchill

Hope this helps as starting point to think about the best methodolgy you will want to use later on.

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

May you attach some little example?

If I've understood well, at the end my single profile is an assembly formed by at most 4 parts/istances (1000/100/10/1).

And I manage assemblies instead of parts. Right?

If it's right, I think it's not the best to manage an assembly with hundreds of profiles and thousand of "sub-profile". Right?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

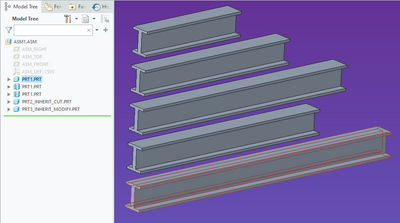

Here is a simple example of using flexibility and inheritance.

Assembly:

First part is the base part.

Second and third part are shortened by flexibility.

* First three parts will show up in the BOM as the same part.

Forth part is an inheritance cut to length.

Fifth part is an inheritance shortened by varying the length in the inheritance.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have many family tables in Windchill for hardware items, mostly bolts and screws, were there are more than 50 instances in the family tables.

I know of at least 1 family table that I have that has over 1000 instances in it.

I do not use nested family tables.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting. I may make, for example, 12 parts; one every 500mm up to 6000mm of the maximum length of the profiles.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've tried with FT with 500 instances and it seem works well.

At the end the single part is simple and each instance has only one dimension (the length) that varies.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I get where you want to have all variations in length available for your design team to pull from, but do you really use all 6000 incremental lengths in practicality? Maybe start with existing designs and see which lengths have been used in the past and put those in your family table. Then add a range of sizes, maybe 5 + and 5 - sizes, around each of those sizes to allow for variation in sizes in the designs.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If your goal is to control the shape of the extrusion, you could create a model of the stock length extrusion and use it as an inheritance for the part model. The length could then be cut to the needed size. You could also vary the length dimension in the inheritance, but that is modifying the inheritance and other dimensions could also be changed.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

My goal is only to have different lengths because the shape is standard

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

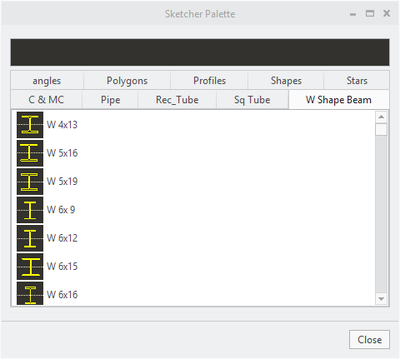

We use the sketcher palette for profiles. So when we create a new part, we create the first feature and select the appropriate structural shape and extrude to the length needed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @GiFra_Label

Here is attached a movie showing the approach from scratch in a Creo Parametric 8.0.2.0 session linked to Windchill 12.0.2.3.

Some explanations on the movie:

- Creo side: dm_custom_checkin_prompt yes (default being no) in config.pro to allow accessing Models and Viewables upon Custom Checkin (required for me, as I did not have a CAD Worker in background when registering the video, but may be useless for you if a CAD Workzer is up an running in your environment)

- Windchill side: In Visualization section of Site level preferences, Flexible Assembly Features in Dynamic CAD Structures preference set to yes to allow displaying the flexibility in components when viewing the Visualization tab of CAD Document TOP Structures

Outcome produced: Same component robounit.prt placed multiple times in a given assembly, with multiple different length driven by a flexible integer parameter (ROBOUNITS_LENGTH) driving the depth of the extrude feature via relations defined at art level.

Hope this helps to have a good understanding of how the notion of flexibility can be used to achive this outcome.

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I know this is an old thread, but I was curious if you would be willing to share your sketch palette database. I would like to build a similar palette, and this would give me a significant head start.

I appreciate the help!

Ryan

- Tags:

- Sketcher Palette

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Unfortunately I can not share the files outside of my organization. Sorry.

When those files were developed in house, we had a user simply come up with the basic shapes based on AISC tables. Once the basic shape was done, he simply used a save as and changed the dimensions for each size.

Since that time, PTC has added advanced framework extension (AFX) and some of our users have started using that instead of the sketcher palette.

There is a learning curve involved in using AFX and software licensing issues if you are looking for larger assemblies.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for the response. We ended up creating start files for each profile type, and each start file has a family table to allow table driven profile sizes. This was an expedient way of getting a similar result.

I appreciate the information and suggestions!

Ryan