Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Bend back fails between 20.47" & 20.48"

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Bend back fails between 20.47" & 20.48"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Bend back fails between 20.47" & 20.48"

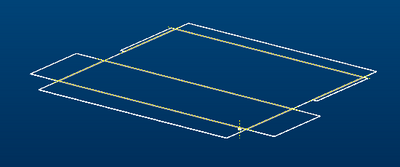

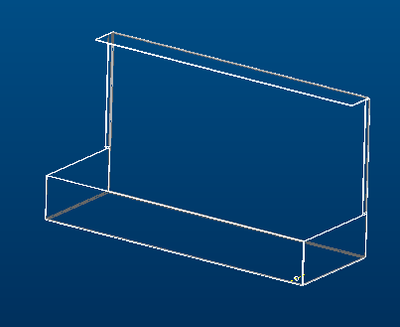

I have a sheet metal bin that was initially 26.69" from side to side. I want to reduce that by 7". At 19.90", Bend_Back_1 fails. I found that @ 20.48" and larger the bend back works and @ 20.47" and smaller the bend back fails.

I cannot find a reason why things are failing when they do. Please find the attached file in a .zip file.

Solved! Go to Solution.

- Labels:

-

Sheet Metal Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @Dale_Rosema

Most of the time, as @Patriot_1776 said, it's enough to modify acuracy in this kind of situations. In this specific one however, i't'e not enough (even with accuracy_lower_bound 1e-5). Better than a long explanations, I registered a little movie showing that:

- Issue is reproduced as per your guidance

- A kind of "partial workaround" could be the redefinition of the Bend Back Feature and select the bends in the "good order" (instead of using the automatic way)

- Above "partial workaround" is nevertheless not enough (because issue then occurs on the successive Unbend feature, and produces a kind of note very far from model, causing "extent issue" leading in graphical issues on screen)

- Root cause is pointing to the 2 lateral Flange Wall features 4 and 5

- Using Flat Walls instead seems to setup a stable situation in this context

Consider this just as a guidance with a willingness to help you getting rid from the current issue, but for sure not as a "resolution". In my opinion, I do not see any valid reason to justify why it's not stable in original conditions (with the Flange Walls 4 & 5), so that:

- If it's an isolated use case, and what I propose here is enough to consider this as a resolution, I think we can just stop investigations here

- Otherwise, if use case is more global, or if you have any concern (even with my approach, or with the fact it just should work in original conditions), I suggest you to open a case to PTC Technical Support for probable SPR creation purpose

I attached also in this post the result (bin_ts.prt) of what I did in the movie fo your reference. Just be careful with this model, as I did the dimensionning very quickly, so that you may need to modify slightly some positionning dimensions of the holes (supposed to be the corner reliefs).

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I took out the bend relief holes and it seems to work???

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Specifically Hole #3 & Hole #4. Why?

If I change Hole #3 from .400 to .500 it works and so does hole #4 and the bend back?

0.407 works (but not .406)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

'Sup Dale!

I haven't looked at the file, but it sounds like an accuracy issue maybe? I don't play much with sheetmetal, but it might be something to look into.

Best of luck!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @Dale_Rosema

Most of the time, as @Patriot_1776 said, it's enough to modify acuracy in this kind of situations. In this specific one however, i't'e not enough (even with accuracy_lower_bound 1e-5). Better than a long explanations, I registered a little movie showing that:

- Issue is reproduced as per your guidance

- A kind of "partial workaround" could be the redefinition of the Bend Back Feature and select the bends in the "good order" (instead of using the automatic way)

- Above "partial workaround" is nevertheless not enough (because issue then occurs on the successive Unbend feature, and produces a kind of note very far from model, causing "extent issue" leading in graphical issues on screen)

- Root cause is pointing to the 2 lateral Flange Wall features 4 and 5

- Using Flat Walls instead seems to setup a stable situation in this context

Consider this just as a guidance with a willingness to help you getting rid from the current issue, but for sure not as a "resolution". In my opinion, I do not see any valid reason to justify why it's not stable in original conditions (with the Flange Walls 4 & 5), so that:

- If it's an isolated use case, and what I propose here is enough to consider this as a resolution, I think we can just stop investigations here

- Otherwise, if use case is more global, or if you have any concern (even with my approach, or with the fact it just should work in original conditions), I suggest you to open a case to PTC Technical Support for probable SPR creation purpose

I attached also in this post the result (bin_ts.prt) of what I did in the movie fo your reference. Just be careful with this model, as I did the dimensionning very quickly, so that you may need to modify slightly some positionning dimensions of the holes (supposed to be the corner reliefs).

Regards,

Serge

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Since I found a work around with the hole size and since this is critical, I am calling your response the answer, but just living with a slightly larger drain hole.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hey.

Since this isn't rocket science and just a drain hole on a fixture bin, I can live with it at a slightly larger drain hole. So I am not going to pursue it further. Just another quirkiness of Creo popping it head up every now and then.

Thanks,

Dale

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo quirkiness??? Say it ain't so! LOL 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think part of the issue is how you are using the program. Specifically Flange 4 and Flange 5 have a 0 inside radius. A better way to achieve the box would be to create the bottom, create a flange around bottom (Shift selecting all fore sides) defining the corner relief, extend the back, flange the top and sides, and extend the top. Attached is a quick example in 7.0.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have to take a look at this later since we are on Creo 4.0.

Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I created a new bin.

I used the shift key to do all four sides.

I extended the back.

I create the top three flanges and extended the top.

Bin will not "Bend Back" no matter what I tried.... that is because I was suppose "Unbend", which once I did, worked fine. 🙂

A lot simpler model tree thanks to the shift key and selecting the (4) side and then learn to extend one of those side.