Community Tip - Have a PTC product question you need answered fast? Chances are someone has asked it before. Learn about the community search. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Bolt Clearance Hole - Assembly

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Bolt Clearance Hole - Assembly

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Bolt Clearance Hole - Assembly

Creo 9.0.7.0

***Disclaimer - (I know) do not put features in an assembly***

But, ...

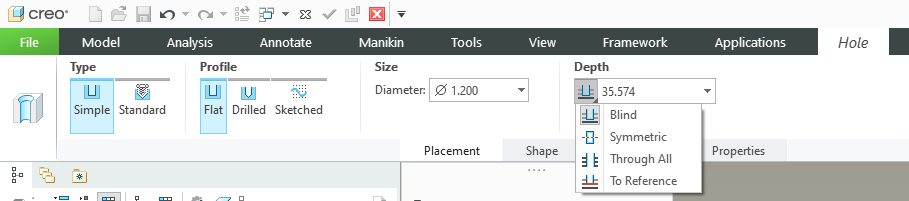

I am putting a bolt clearance hole in a 2" square tube assembly. I thought that I used to be able to specify a depth of the clearance hole, but now my only options are (1) through all and (2) to a reference. Since it is a tube, I do not want to go all the way through both walls.

Did something change or am I missing something?

- Labels:

-

Assembly Design

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you change the hole type to simple you will get the specify depth option. This behavior is the same in Creo 7 and Creo 9 on my machine.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I noticed that too.

But why not with a clearance hole? Oversight?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It seems odd that it is missing for standard holes. It would be a rare occurrence for me to use an assembly feature to add the hole, so I have no history for this scenario. If no one offers an explanation here I would open a call with support on this one.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Use the 'to reference' and select the inner wall of the tube. If your wall thickness changes, the hole will update to the "thru" depth. No need to determine the depth. Being a clearance hole, I would guess it is going through and not being a blind hole.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That too is a valid option.

I seldom use "To Reference" but I did on this one, but the refence I used was the center planes on which the tube was built.

I was just surprised that I could pick a depth so I didn't know if something changed.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

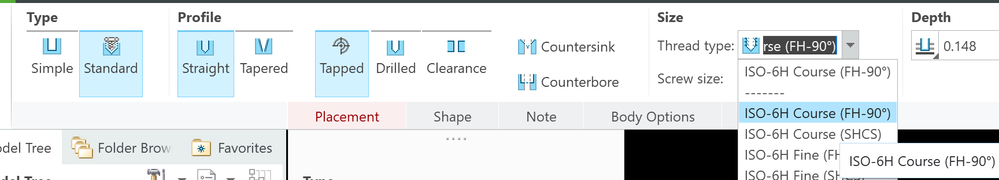

Now remember, we ARE talking about a company (PTC) that doesn't know the difference between a "COARSE" thread (i.e. ISO or UNC) and a "COURSE" thread...🤣🤣🤣

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The "COURSE" (LOL) thread issue has been a mistake for a while now, I THINK (not 100% sure) from back in Creo 4, and is probably even older than that. So, any bets as to how many more years it will take PTC to fix it? Anyone? Bueller? Should we get a pool going?🤣

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've got a sneakin' suspicion.....

... maybe it has taken it's course (or was that coarse?).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

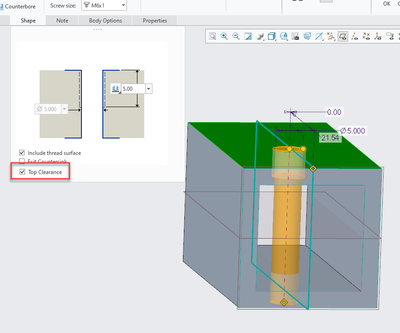

Since it is a clearance hole, I'm trying to think of a situation where you would need to specify a depth. If you are going to tap the opposite side of the tube, you can create a tapped hole and add a top clearance and specify the depth of the clearance.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Just a simple clearance for bolt coming through a washer and attaching to a custom loose nut on this inside.

Thanks,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Right, so there is no reason to enter a specific depth. Using the inside surface as a reference would be the proper way to do this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No, in THIS case (square tube) that would work, in others, no.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Plenty of reasons to specify a depth on a clearance hole: You are using a pin to locate 2 parts relative to each other and you cannot drill thru because there is liquid, pressure, or something on the other side (industrial washdowns, weather, etc.) that you cannot have coming thru.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Then that's just a "simple hole", not a "standard hole". A standard hole, which includes clearance holes, is for threaded fasteners.