Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- COMPOSITE MATERIAL, LAYER PROPERTIES and ORIENTATI...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

COMPOSITE MATERIAL, LAYER PROPERTIES and ORIENTATION

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

COMPOSITE MATERIAL, LAYER PROPERTIES and ORIENTATION

Hi all,

I'm test the feature "shell Properties" and "Material Orientation" for a simple part.

The example is attached

When put the boundary conditions... I believe that all is correct, more or less I followed the steps of other post in "PTC User Community" about composite and layer properties.

Finally I don't understand the results... because it should to have moving straight and not to turn.

See the images in the files attached.

I hope you can help me.

Thanks

Gorka Garcia

Integral Innovations Solutions

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Gorka,

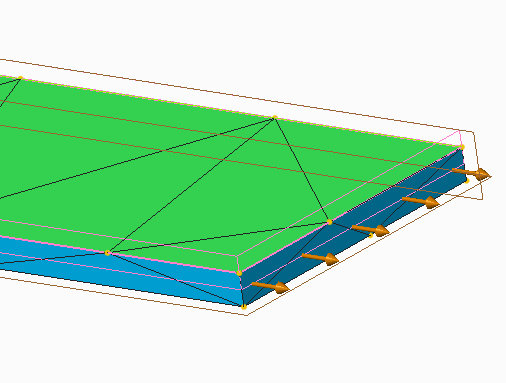

In your example you have defined a mixed shell and solid model. The solid extrusion is being meshed with solid tet elements, and you have applied a shell "coating" to the top surface of the solid.  See attachment for preview of your mesh. Not sure if this is what you intended? If you want a shell only model you should either define shell pairs (Refine Model - Idealizations - Shell Pair...), or use a thin feature when you make the extrusion, or create a surface (not solid) feature. You have in essence made a solid block then added stiffness on one side. Hence it is no longer symmetric, and thus you will see deformation to one side (it bends like a banana!)

See attachment for preview of your mesh. Not sure if this is what you intended? If you want a shell only model you should either define shell pairs (Refine Model - Idealizations - Shell Pair...), or use a thin feature when you make the extrusion, or create a surface (not solid) feature. You have in essence made a solid block then added stiffness on one side. Hence it is no longer symmetric, and thus you will see deformation to one side (it bends like a banana!)

Also, your material is isotropic, whereas for composites you'll probably (definitely?) want to use a "transverse isotropic" that allows you to define properties in fiber direction. When you do this, the material orientation you define will be meaningful.

Finally, your layup definition has the same material and same orientation for all layers. You could have done this with a simple shell definition of 1mm. Granted you can now go back and add a thick foam core layer (perhaps in between plies 2 and 3).

I hope this helps? Please let me know if I have misunderstood your question.

Greg

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Mr Brown,

Thank you for your answer.

Yes, I defined a mixed shell with solid... because is what I saw in this post:

Re: Creating a part with multiple material layers (Mats Lindqvist)

I explain you:

1st: I need build a laminar solid of 1mm. But using Shell properties with layers of 0.25mm

2on: Each layer with different direction and same material

Using the same example as Mr Mats Lindqvist... I believed understand that the procedure was correct for calculation.

Br,

Gorka