- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Design for corner clearances to accept rectang...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Design for corner clearances to accept rectangular corner in milled depressed feature.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Design for corner clearances to accept rectangular corner in milled depressed feature.

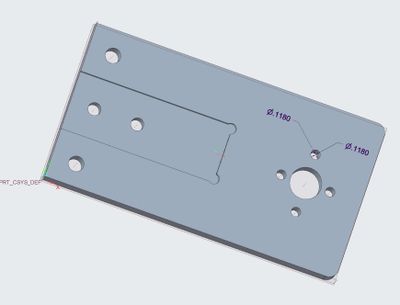

The picture shows the "ears" I add to rectangular depressions in a part so that the fillet left by the milling cutter will be removed and I can bolt a rectangular part with sharp edges into the depression.

Is there some better way to handle this problem in Creo? What do you do?

As a footnote, we used to call a depression like the one shown, a "dap." Is there a better term now in use?

Solved! Go to Solution.

- Labels:

-

Assembly Design

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

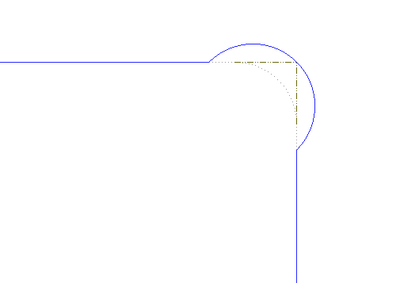

Here's a possible method, you might find a better one:

(1) Do the cut with the sharp corners.

(2) Do a separate cut for the "notches". For each corner:

(a) Create a construction circle of the desired notch diameter.

(b) Make that circle tangent to both walls of the corner.

(c) Make a construction line from the center of the construction circle to the corner.

(d) Make a geometry circle, same diameter as the construction circle, center on the construction line.

(e) Make edge of geometry circle coincident with corner.

(3) Repeat for all the corners.

A bit of work, but fortunately only one dimension needed, for the initial construction circle.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If this is something you need often then I would suggest creating a user defined feature (UDF). You can include the pocket and the corner cuts in the UDF and then place it in models as required. You can create a library of different sizes or use one UDF and edit the dimensions after placement. See subordinate and stand-alone UDF options.

UDF help files:

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's really about what your mating part looks like. If I was in control of the mating component, I would prefer to add a chamfer or radius to the other part that clears my expected or specfied corner radii on this part.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I agree that it would be better to radius the mating part, but in this instance, it would be more difficult that adding the 'ears'

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've built things where I wanted to minimize the depth I'd cut out of the wall to relieve the corners, and the above "trick" worked really well for me. The presumption is that I'm going to be cutting the pocket or whatever with a specific diameter tool, so I cut any possible interference out of the resultant corners with the minimum material depth normal to the wall faces. Works well when I have ample wall length to interface with the mating part, not such a good idea with shorter walls.

Hope it's useful.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ken, How did you do it? Two arcs? I did mine by adding a circle with center inside the corner, then reducing the offsets from each die until I got the geometry I was seeking and deleted the extra line segments. It's funny that SheetCAM, a program I use for running the CNC router offers this as a toggle, which can be a real time-saver when doing a sheet with a lot of cutouts which require the corners not to be radiused.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here's a possible method, you might find a better one:

(1) Do the cut with the sharp corners.

(2) Do a separate cut for the "notches". For each corner:

(a) Create a construction circle of the desired notch diameter.

(b) Make that circle tangent to both walls of the corner.

(c) Make a construction line from the center of the construction circle to the corner.

(d) Make a geometry circle, same diameter as the construction circle, center on the construction line.

(e) Make edge of geometry circle coincident with corner.

(3) Repeat for all the corners.

A bit of work, but fortunately only one dimension needed, for the initial construction circle.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Ken,

Something I picked up many years ago was to make features which might be tricky really big especially where dimensions would be close to other dimensions. This way I can get the relationships (dimension scheme) what I want and then I edit each dimension until I get what I want..