Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Different Color Areas on Same Surface

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Different Color Areas on Same Surface

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Different Color Areas on Same Surface

We have a requirement to highlight areas of a casting model as zoned areas, where the zoned area has specil requirements, ie cannot be repaired with welds etc. We usually do this by highlighing the areas by drawing sketches on the drawing views. We thought it might be a good idea to show these surfaces as different coloured surfaces in the 3D model so found a way on youtube, where a guy showed how to change a particular surface to transparent, then copy and paste a new surface over the transparent surface, which could then be split into 2 surfaces, with one being the colour of the original part and the other surface being coloured to a new colour to highlight a special attention area. Our current policy for casting to machined, is to take this casting model, create a new part for the machined and then merge the casting into the machined model (using Get Data > Merge/Inheritance). Unfortunately, when we then apply machined cuts to the machined part, these newly created "coloured" sufaces, used to highlight areas of concern are not cut.

Has anyone any ideas if this can be acheived. would be so much easier if the original surface of the extrude/revolve etc could be split and coloured seperately.

Thanks

Stu

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

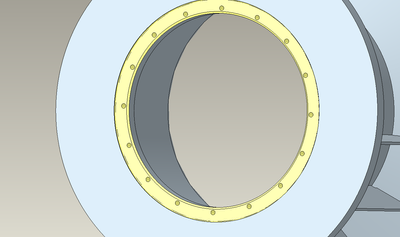

I have employed your suggested approach to specifying the surface finish on molded parts (see pic). Create a copy of the surface that you need to highlight and then assign the color to it and put it on a layer. In the example shown a copy of the solid surfaces was created as a single feature and then colored to designate finish.

If you need to "split" a surface then trim it and retain both sides of the trim operation. This will allow the region to be defined but does not often render well in shaded images. You can also retain only one side of the trim operation to maintain the underlying color of your cast part in contrast to the designated area.

You could also take a look at cosmetic sketches which may also support what you need to do. You can define regions on a surface and then add hatching to designate the area of interest.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for replying...this was our original strategy, to copy and [aste a new surface over the existing surface of the solid part, then colouring the newly copied surface. However, we were experiencing a lot of color mis-match called aliasing, as shown in attached picture. We discovered another method where the original portion of the solid model was changed to a transparent "glass" colour which stopped the aliasing. But with this method, we have to leave the copied coloured surfaces on the model so that it represented what looked like a 3d solid component. The problem arose when we came to machine the original part. this seems like such a simple thing to be able to do, but cnnot do.

Stu

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is an example of an as machined casting using inheritance feature. The orange surfs are an example of what you want if I understand correctly. The colored quilt is a feature in the as machined model, not the parent as cast model. Does this represent in a general sense what you need? If it does then you can use the method I described above to achieve this.

I don't think what you are observing as undesirable is aliasing in your shading image example but I understand you want to avoid that. It is more likely an interference pattern of two congruent surfaces shaded simultaneously.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, and once again thnks for the effort of replying.

Yes, this is what we are looking for, to indicate what faces are later machined. We also want to show areas in the casting where there are to be no weld repairs etc, so would have to copy the surface, and split with sketch line or plane intersection.

You mentioned that the orange areas are a quilt feature in the as machined model, what is the reasoning behind putting this feature into the machined model and not the cast model

You also mentioned in your last reply, here is a machined part taken with inherited features from the cast model. We have decided on the merge part of that Get Data command, so that the cast features cannot be modified in the machined component. Do you know of any "best practice" guide as to why merge or inheritance should be the chosen feature when bringing in the cast model into the machined model.

stu

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

For machined areas on my merge models, I change the color of all the solid surfaces of the part to be different than the part solid. I don't like inheritance simply because you can modify the cast dimensions from within the machine model. I'm sure there are good reasons to use it but it doesn't fit my thought process

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Steve,

Yes, we are doing that too, colouring are machined faces a different colour in the cast model. These transfer into the merged machine part too, and when machining cuts added to the model, the coloured face will be removed by the cut. I, like you, prefer the Merge part of the Get Data > Merge/Inheritance for exactly the same resoning as yourself. We want the cast to be unchangeable while in the machining model.

The problem we faced was that certain areas of certain faces need to be deemed as special zones, ie not to be repaired etc and thought would be good to highlight these with different colours than the main model. Problem arose when it was just a portion of the surface we needed to highlight and when we copied and pasted a new surface over the old surface, then split this new surface at the require position, coloured the required side of the split surface to a different colour, we encountered a striping effect between the 2 different colour, ie original and new, which when we looked online was desscribed as aliasing, but we are not sure if this is the correct terminology.

Stu

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The enclosed zip file has an old article I published when inheritance features were new in Pro/E (2002). It has comparison of merge vs inheritance and covers machined casting models.

Download these to a shared folder and open the e-profiles... html file for the overview and the other two for casting models and options for inheritance features. It is not 100% but you will get the relevant information which is still valid as far as I know.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I haven't seen a Pro/Files magazine in years. Used to save them and Pro/E-The Magazine. Brings back memories!

Based on this, maybe I have always mis-understood inheritance features. Not sure.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks both for replies. We chose the Merge part of the Merge/Inheritance purely on the basis that you cant modify any of the features from the original model when using Merge. Inheritance allows the modification of the imported features.

This thread had slightly gone off track as my original question was regarding colouring of surfaces of parts and how to get around having the mis-match of colours when we overlayed one surface on top of another (using ctrl c + ctrl v to copy the surface).

Stu

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

>> "Create a copy of the surface that you need to highlight and then assign the color to it and put it on a layer."

Are there any tutorials / video clips on how to do exactly this?

Do you have any helpful links to any articles treating this matter?

Many thanks!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Note also that now the divide surface tool is available to better highlight your design intent:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can you post the link to that YouTube video/tutorial please? Thank you!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Designate under Model Intent, added in 3.0, might be a better tool for what you are trying to accomplish.

There is always more to learn in Creo.