- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Direct Digital Simulation by using CutOut and Patt...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Direct Digital Simulation by using CutOut and Pattern

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Direct Digital Simulation by using CutOut and Pattern

Hi.

My name is Jan.

I try to generate geometry of face gear by easy way. Direct Digital Simulation. The principe is to pattern pinion part over face gear to simulate meshing. I used pattern to copy pinion part and than I done CutOuts between Face gear part and pinion part. But it is long and no correct process. I would like to do one CutOut and than apply Pattern on this CutOut. I don t able to find correct positioning. I want to use Pattern by Dimension, when I have to define two dimensions (angles) and inkrements to simulate motion by gear ratio. Is there any restrictions in using pattern and CutOut. Have you any experiencies with Direct Digital Simulation. Is it possible to do any continously CutOut to simulate meshing of gears?

Thank you for thinking about my problem.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

2D Drawing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Jan and welcome to the forum.

Gear teeth can be very challenging to those of us who simply cannot grasp the theoretical concept behind their development. In my world, I let the experts deal with the details while I understand the functional requirements.

One thing I do know is that gear teeth are can also be very forgiving if you use compliant materials.

For the gear you are trying to make, to the best of my knowledge (or recollection), it is treated like a rack gear tooth. They are typically straight faced and can be determined by the pinion's pitch diameter. They are also typically very narrow so they don't bind. Typically you find these in an erector set where these are stamped from flat stock. For any kind of serious duty, you would choose a bevel gear. The idea is that you would use these gears only in light duty applications so that a narrow tooth profile will suffice. Think of it as a narrow rack gear twisted into a circle.

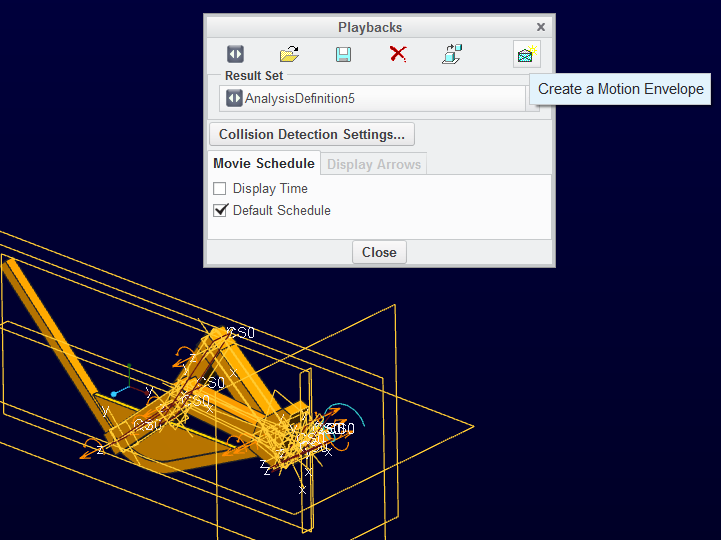

As for capturing profiles, have a look at the Mechanism tool. You can actually give a gear motion and make a solid from that motion envelope. Pretty neat stuff. If you create a mechanism analysis where the pinion rolled along it's pitch diameter around the face gear, you can get a pretty good profile of the motion path very similar to what you are doing now with the patterns.

Here is some info on this... have a look in the help files:

Create the motion envelope as the following steps:

- Create an assembly file and assemble related components with proper connections

- Applications > Mechanism

- Apply Servo Motor to the desired connection

- Create and run an analysis

- Analysis > Playback

- Click Creat a Motion Envelope icon

- Set Quality Level

- By default all the related components are selected

- Uncheck Ignore Skeletons and Ignore Quilts options if necessary

- Select Output Format

- Preview

- Create

- Create trace curve as the following steps:

- Insert > Trace Curve

- Select a part as Paper Part

- Select a point or vertex as trace curve reference

- Select 2D or 3D as Curve type

- Select one analysis result from Result Set or open one existing analysis result

- Preview

- OK

So the bottom line is that the gear you are making is a special application. If the tooth thickness is significant, they will have a inward taper to them as you show. But again, typically these would be made as bevel gears at that point. Face gears are simply more forgiving with taper angle and other parameters that make them more universal.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Antonius,

Thank you for your advice.

I have not Mechanism modul, and I use old version of ProE Wildfire 2.

I know, that my way is not full correct, but I wanted to try it.

I have real problem to find manufacturer of special hobbing tool for Face gear (modul 0.28mm). Geometry of hobbing tool has to be created on base of pinion geometry, but I dint find any manufacturer of hobs, who understant this teory about face gears. All manufacturers asked for tooth geometry of face gear, but I think that for building of hob is necessary geometry of pinion, which I have.

I wanted to learn more about teeth shape of face gear.

In my aplication I can not use bevel gears becouse of technology and dimensions.

I need 3D model to create prototyp by milling proces.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is indeed an unusual application. I have a strong recollection of such a gear from my erector set as a kid. They run against normal pinion gears and from what I remember, they were very noisy.

Put this into Google: "Meccano Contrate Gear Wheel"

Notice that these have very straight gear tooth cuts. They are actually formed gears where the teeth are created in the flat and then formed to be 90 degrees.

The other very common application is the slot car gears. They typically use a straight pinion and this type of gear on the axle. There is normally a significant ratio for these applications.

Again, I see this as a light duty application considering the actual contact face is very narrow unless you have a very specific pinion with tapered teeth.

Here is another name for this style: Crown Gear http://en.wikipedia.org/wiki/Crown_gear

What you are doing is the right way to go about it. I am not able to find the "correct" way to specify these as "90 degree bevel gears" as Wiki explains them. Can you share the application?

As for machining, if you need them out of steel or brass, I would say a mill with a shaped cutter or interpolated blade should work. Technically, a hob should work if the tooth thickness is narrow enough or if the extra rows are removed from the hob. But again, I think the proper profile is that of a rack rather than a pinion. If you need a shape as you are defining with your model however, this is going to take a special cutter and a more precise "depth".

If you want, I might be able to help on the profile based on what you are trying to do using Mechanism. I will need some more information, however to make sure the setup is correct.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is an interesting little note on face gears... http://www.grc.nasa.gov/WWW/RT/RT1995/2000/2730h.htm

The picture is pretty clear as to how the teeth vary their face angle as the radius gets larger.

This image shows this pretty clearly as well:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for a good tips of links.

I have studied many articles and studies.

The main problem is, that I am not able to find suitable manufacturer of special hobbing tool as you can see on the picture. I want to use technology of hobbing, because company where I work has it.

Please, coud you recommend any good manufacturer of hobbing tools, or any good forom, where I could find specialist for this type of tools?

My application:

Dental contra-anle handpiecies with ratio 1:5.

Thank you for your interest.

Jan

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am not very familiar with tool and die manufacturers or forums but that would be the direction I would consider.

I have no idea how that hob would machine that twisted plane. When I need help with gears, I go to these guys: http://sdp-si.com

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Unlike a broach, a hob is moved axially while rotating in synchronous motion with the face gear - the shape of the teeth is the result of that combined action. The trick is to avoid removing the tooth surface that carries the load as the mating gear hob teeth come in and out of mesh.

If this was a zero face width face gear, the tooth profile would be a straight tooth rack**, bent in an arc at the mating radius. Since the width is large in comparison to the gear diameter, this shape gets expanded or contracted in ratio with the radius change.

**Assuming the hob is an involute gear tooth form.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's an interesting problem. Check out Gleason dot com and GearTechnology dot com