Community Tip - New to the community? Learn how to post a question and get help from PTC and industry experts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Driven pattern

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Driven pattern

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Driven pattern

Hello,

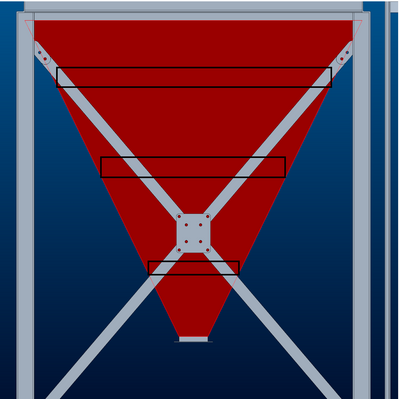

I have a problem, that I need to create pattern of metal sheets (see attachment), that changes his length according to inclination of dump and number of reinforcement (in the picture there are 3 but can be more or less according to type dump). It's only done by extrusion, so it's not assembly but part. Any suggestions how to do it?

Thanks

- Labels:

-

Sheet Metal Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Assuming you have a license that includes the top down design tools, use of a skeleton is straightforward.

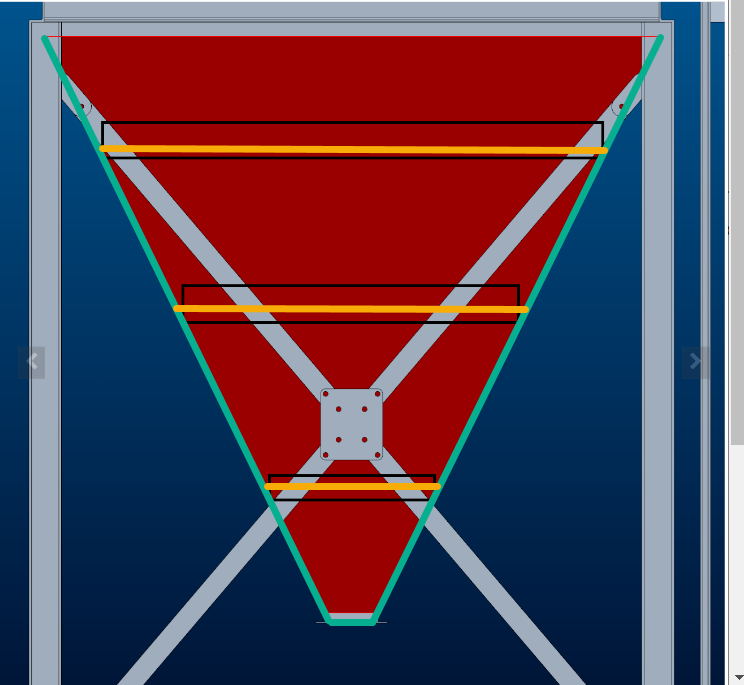

Create a skeleton model (2D curves and datums) that controls the inclination (angles) of the dump. Add a pattern of curves representing the location of reinforcements. If you align the endpoints of the curves to the inclination angle curves then they will stay attached, you can then alter the inclination and number of reinforcements in the skeleton model . Use this skeleton to control your part models and it will update from the skeleton.

The skeleton could be as simple as coplanar curves shown in green and orange below.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

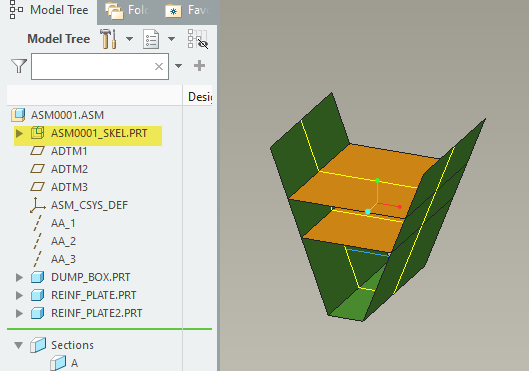

Enclosed is a Creo 7 model demonstrating use of skeleton to drive the plate locations and width. It can of course be much more sophisticated to capture additional design intent if desired. If you can define the location and number of plates as a function of the dump box orientation and size that could be included in the skeleton model using relations to control the geometry. You can manipulate the dump box and plate parts (.prt models) within the skeleton model shown in the tree below.

I have oversimplified the geometry and used surfaces curves/exclusively, but it will work for solid part models.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric