Community Tip - New to the community? Learn how to post a question and get help from PTC and industry experts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Having trouble with the hole table.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Having trouble with the hole table.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Having trouble with the hole table.

Hi, anybody who reads this. I'm a new Creo 2 user, I used Pro years ago, but that's a different beast altogether now. I have been using Solidwotks exclusively for about 8 years and my new job needs me to do some work in Creo, and I'm flying blind. I have managed to model up all the sheet metal parts fairly well, with the exception to hole patterning. I have a metal strip that will need 139 instances of a home all in a straight row. The problem is that the spacing follows a pattern of .625 distance on first, .625 on second, and .500 on third. It goes on just like that for 139 holes. Ok, so I can create a table and enter in my distances and it works in theory, however my "standard" hole spacing is from home to hole whereas Creo seems to want to use the first features reference to the edge and dimension everything from the edge ordinate style. Am I wrong? I even went so far as to manually calculate each hole position and plugged everything into an excel file, as someone said it could be used as long as the extension was changed. Unfortunately I spent all that time and I can figure out how to bring it in. Sorry for the long message, I was trying to cover everything done or tried. Any pointers would be greatly appreciated now that I'm switching teams;)

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

2D Drawing

- Tags:

- dimensions

- hole table

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mark,

pattern_hole_test_mh1.prt

- added DTM1

- first hole dimensioned to DTM1 ... 0.625

- second hole dimensioned to first hole ... 0.625

- third hole dimensioned to second hole ... 0.500

- three holes are grouped

- group is patterned 46-times ... dimension pattern using dimension 0.625 from first hole and increment 1.75 (0.625+0.625+0.500)

- problem of this model ... last hole (no.139) is missing

pattern_hole_test_mh2.prt

- added DTM1

- first hole dimensioned to DTM1 ... 0.625

- second hole dimensioned to DTM1 ... 1.25 (0.625+0.625)

- third hole dimensioned to DTM1 ... 1.75 (0.625+0.625+0.500)

- first hole patterned 47-times ... dimension pattern using dimension 0.625 from first hole and increment 1.75

- second hole patterned 46-times ... dimension pattern using dimension 1.25 from second hole and increment 1.75

- third hole patterned 46-times ... dimension pattern using dimension 1.75 from third hole and increment 1.75

Martin Hanak

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

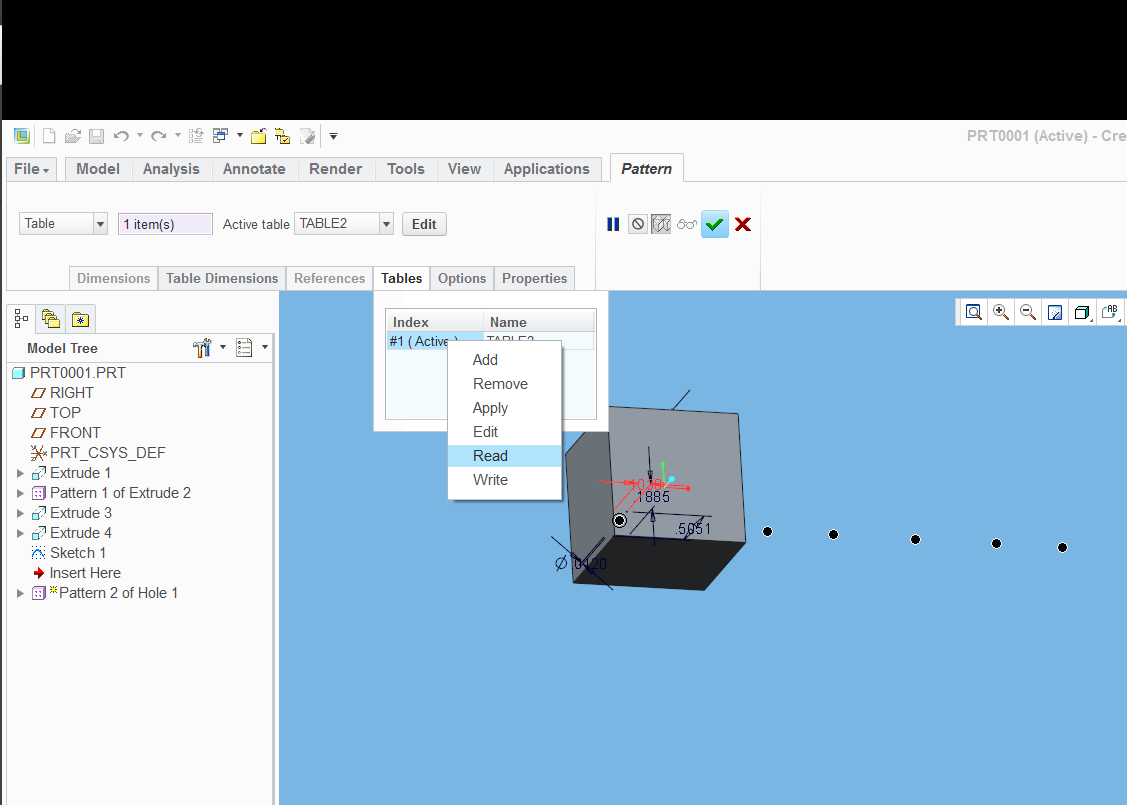

It sounds like your question is in regards to a table pattern. Just to be clear, a hole table in the PTC world refers to a table that gets put on the drawing.

To answer your question however if you are using Creo2, when you edit the table it should come up in Excel. I do not believe you can define the distance between holes with a table pattern. When you are finished filling out the dimensions, click save in Excel and then close it. You will get a prompt about keeping it in the same format. Make sure to say YES. When you close Excel it may ask you if you want to save again. You can click don't save.

Alternatively you could define your hole pattern as a point pattern. Sketch out a bunch of points and then pattern based on the points (last option in the pattern drop down). This would allow you to define the space in between the rows of holes.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for the distinction. Yes, I made a table, patterning one hole in a long row. The problem is that I can vary the distances as needed but only if they are dimensioned from the same edge as the original holes placement. I have hole to hole dimensions, and forcing me to manually enter each location after subtracting out the original edge dimension and each consecutive hole thereafter if that makes sense.

I don't think I'd be saving much by sketching out the points I'm afraid; I would need to plot out 140 instances. Maybe I'm not understanding. Thanks for trying to point me in the right direction.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Martin,

Thank you very much for taking the time to create a sample for me. The issue is that while I can plot out dozens of holes on a table, the issue is dimensioning them. For instance, you made a representative sampling of the spacing, and then patterned that group of holes 4 times? Where/how do you control that 30mm gap between each extrude instance? I need to have the pattern repeating without additional spaces. Did you follow that? I know I'm close, maybe your method will work, and I just haven't figured out how to completely control it.

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Have you tried patterning a pattern?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

After I played with your sample a bit, I was able to re-create exactly what I needed done on your model, however I could not replicate on mine. For some reason it just wont accept 2 different dimensions. I can pattern an extrude of anywhere from 3-5 holes, and when I give it a distance in the edit screen, it will ultimately only patter that dimension regardless of the fact that holes of different spacing were in the base extrusion. What am I missing here? Thanks again for your help as well as everyone elses.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mark,

if you want to get an answer to your question, please upload your file. See How to upload Creo (or other) files

In my example I created 3 holes in Extrude 2 feature. If you go to Sketcher mode to investigate its section, you will see that:

- center of 1st circle is dimensioned to vertical sketcher reference

- center of 2nd circle is dimensioned to center of 1st circle

- center of 3rd circle is dimensioned to center of 2nd circle

If you edit definition of pattern, you will see that:

- I used Dimension pattern

- I used dimension related to the first hole placed 10 mm distance from RIGHT datum plane

- I decided to use 60 mm increment - this means that first occurence of Extrude 2 feature is located at 10 mm distance from RIGHT datum plane, second occurence of Extrude 2 feature is located at 10+60 mm distance from RIGHT datum plane, and so on.

Martin Hanak

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Martin,

Thanks for your help. I had immediately looked at how you created it, and the options, but cannot seem to get the desired result.

So, what is needed is a pattern consisting of a #10 hole over a hundred times. The first hole is located .250 from a horizontal edge, then the second instance will be .625 (from the first), the third will be .500, the fourth will be .625, the fifth will be at 6.25.

So the pattern needs to be .625,.625,.500 distances from one other in one direction only.

I'm not sure if this is circumstance where using the "Define increment by relation" should be used or not.

Let me know if you have any idea, and thank you again.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Mark,

pattern_hole_test_mh1.prt

- added DTM1

- first hole dimensioned to DTM1 ... 0.625

- second hole dimensioned to first hole ... 0.625

- third hole dimensioned to second hole ... 0.500

- three holes are grouped

- group is patterned 46-times ... dimension pattern using dimension 0.625 from first hole and increment 1.75 (0.625+0.625+0.500)

- problem of this model ... last hole (no.139) is missing

pattern_hole_test_mh2.prt

- added DTM1

- first hole dimensioned to DTM1 ... 0.625

- second hole dimensioned to DTM1 ... 1.25 (0.625+0.625)

- third hole dimensioned to DTM1 ... 1.75 (0.625+0.625+0.500)

- first hole patterned 47-times ... dimension pattern using dimension 0.625 from first hole and increment 1.75

- second hole patterned 46-times ... dimension pattern using dimension 1.25 from second hole and increment 1.75

- third hole patterned 46-times ... dimension pattern using dimension 1.75 from third hole and increment 1.75

Martin Hanak

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Also I changed relative accuracy value from 0.0012 to 0.0001.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fantastic! Thank you so much for your help and time, certainly takes some circuitous methodology that clearly only lots of experience can yield. I will save all related notes and the 2 different approaches for my cheat sheet folder:)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Glad to be of help i needed to figure out this method so thank you for motivating me ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If I understand your question, you want a repeating pattern of three(?) holes, with two gaps of .625" and one of .5".

Have you considered modelling three holes (individually, using Copy And Translate, or using a pattern table) with spacing of .625" and .5", and then grouping them and patterning the group at intervals of 1.75"? 139 doesn't divide by three so you may need to model one more individual / copied hole at one end...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, that is precisely what I need.

I did try that as well, a few ways. Maybe I was under the wrong type of pattern or I don't completely understand how each type of patter translates. I didn't use "Copy and Translate" however. I just made the holes and tried to select them under the pattern dropdown, I may have chose the wrong option in defining it resulting in it not working. I am not finding it very intuitive. I had online support do screen session with me, and he couldn't figure it out, he emailed me a link the next day referring to making tables:) I guess I need to start looking up copy and translate. The real problem has been with the table only wanting to dimension from the original edge rather than hole to hole. I'm going to explore your method now.

Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The issue of dimensioning edge to hole verses hole to hole could be solved by adding a DTM plane for the distance from edge to fist hole then dimensioning first hole to DTM plane 0.00.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, thank you, I gave it a shot. It seems to only want to pattern one hole out of the extrude of 3-5 holes. Seems like there should be some manner of doing this that does not require hours of manipulating and trial and error. Worse case scenario, I plotted all of them in excel, but unfortunately that errors out when I try and bring it in even after changing the file extension. Your idea seemed like it had merit, but I had tried something similar whereby i would just leave off the first instance so it wouldn't influence the pattern. Then I would just add that first odd spaced hole as a separate feature. I'm willing to try out each and every thing suggested lol

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Very helpful, thank you.