Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: How to Control GD&T decimal places with duel ...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to Control GD&T decimal places with duel dimensions?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to Control GD&T decimal places with duel dimensions?

I have a to give a position tolerance of .003 [0.07] (Inch [mm] )

When I am giving .003 as primary the secondary units showing 0.08

The actual conversion of .003 inches is 0.0762 mm. so it is rounding up.

so then I have entered .0027 so that it could be round up to 3 decimal places and it will show 0.07

but it is showing .0027[0.068]

how can I control this decimal places in GD&T

Regards,

Sundar Dannana,

Mechanical engineer.

Sundar Dannana

Mechanical Engineer,

ExtruDesign.com.

- Labels:

-

Sheet Metal Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

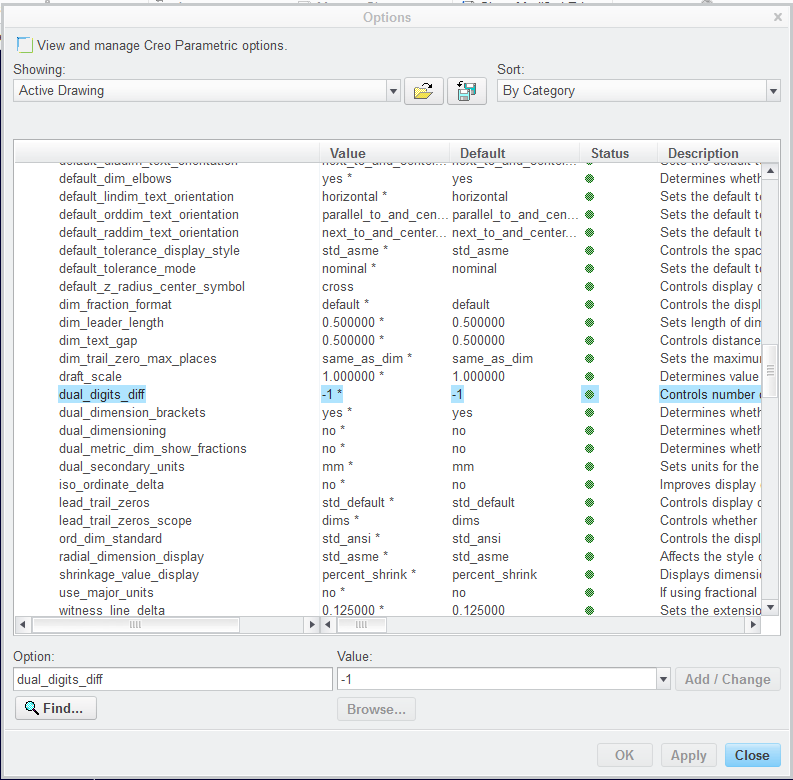

Dual_digits_diff in your detail config.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This will change ALL of them. I don't think there is a way to change just one GTOL's digit difference.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @TomD.inPDX

thanks for your reply.

Dual_digits_diff make the secondary unit decimal placed difference

For example, in this case, if I enter the four decimal places in Inches like .0027, in secondary units it will show three decimal places. this is not the thing I want.

what I want is to show 3 decimal places in inches (primary unit) even if I enter a four decimal number. it should round up to three decimal places when I enter four decimals number.

Example: if I enter 0.0027, it should round up and show 0.003 in GD&T. Like that.

then it will automatically show the conversion in secondary units as 0.07

FYI

Sundar Dannana

Mechanical Engineer,

ExtruDesign.com.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We run into this all the time. The best you can do is increase the number of decimal places displayed.

In my opinion, Creo should really be rounding down the dual dimension value for GTOL's. Rounding up often causes the secondary value to exceed the specified limit.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The real answer is to stop using dual dimensions. Between truncation and rounding no one is happy.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello, @dschenkenRemoving secondary units solve the problem but it is mandatory to show the duel dimensions in my case.

thanks for your reply.

FYI @TomD.inPDX @TomU

Sundar Dannana

Mechanical Engineer,

ExtruDesign.com.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is duAl dimensions, and you can use +1 to have more places or 0 to have the same number of places.

Also, compare the actual number you are displaying to the conversion and you will see there can be 10-25% mismatch between the conversion and the tolerance leading one facility to make parts that will fail at another facility and will probably fail in use.

Duel = try to kill someone with a gun or a sword while they try to kill you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I thought either the stanadrd or maybe another CAD vendor stated that the dual tolerance values should always be rounded down, so it is actually a tighter tolerance and a bad part can never be made.

We used to use a conversion table, listed as being reference only values, that would be put on our drawings in Unigraphics wihich would show the metric drawing value and the converetd english one. With Pro/Engineer, we had to drop that practice since we could not duplicate the table format by grabbing the dimensions off the face of the drawing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There are two issues going on here.

First of all, making the CAD tolerance .0027 and the print tolerance .003 is a poor way to disseminate information.

I strive to make the model dimensions and tolerances exactly what will be on the drawing. If the tolerance was truly .0027, that is what the drawing will show.

The second issue is how to manage dual dimensions and how they should be treated.

If PTC is wrong in their interpretation of the standards, I am not aware of it.

Therefore, I can only suggest that the implementation is per the international standards as far as they are spelled out. Trying to force something else out of the system will only frustrate the user.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

frame table how to 1.0 value in gd&t.