Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: LISP for part rolling a angle by step

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

LISP for part rolling a angle by step

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

LISP for part rolling a angle by step

Hi~

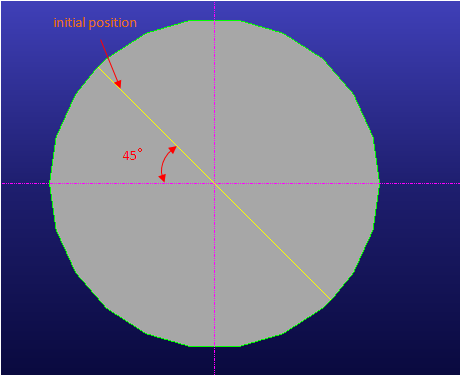

I programed a LISP for a blank to roll one angle 0.9° step by step.( see the attachment LISP file)

Because position_pa command is a terminate action,so I use sd-call-cmds function in the LISP program.

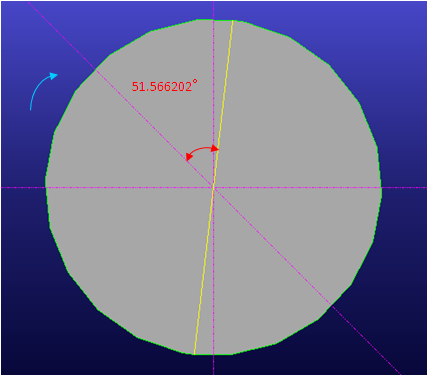

When I ran the program to roll the part 0.9°,actually rolled angle was 51.566202°.

Does anybody could tell me why?

How can I achieve my purpose to roll 0.9° step by step?

Thanks

Justin

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Justin

I am not 100% sure of the answer, I can give a best guess. The calculations are done in lisp which requires radians. Modeling takes a degree input and converts it to radians for calculations.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Justin,

I do not know much about Lisp programming,

but I see the cause in radiant.

1 rad = 180 ° / Pi = 57.295779513082320876798154814105°

° 0.9 = 51.566201561774088789118339332695° ![]()

It revolves around 0.9 radiants and not around 0.9°

Best regards

Friedhelm

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Friedhelm,

I know that 0.9rad equal 51.566202degree.

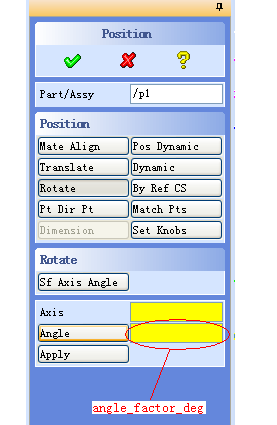

In the LISP using position_pa action have to set the angle in degree. So I set a variable angle_factor_deg.

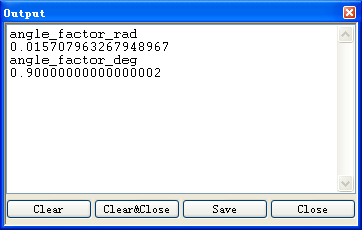

Ran the LISP,you could see variable angle_factor_deg value was 0.9.

Justin

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A couple of tips These will replace some of the work you did.

(sd-deg-to-rad angle)

(sd-rad-to-deg angle)

Lisp works in radians despite what units you have set.

So simply change the line from

:rotation_angle angle_factor_deg

to

:rotation_angle angle_factor_rad

regards

Tom

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

you could also use this line.

:rotation_angle (sd-deg-to-rad .9)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tom,

I know the function sd-deg-to-rad and sd-rad-to-deg.

In the LISP I defined a function g_test() that can be call to do roll part angle.

When push the button to call this function with " (sd-call-cmds (g_test))",the result is the part roll 51.566202degree.

Change to call the function without sd-call-cmds, the ruslt is the part roll 0.9degree.

I can not understand why produce different results with sd-call-cmds or not.

Justin

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is a question that I am not really qualified to answer. I am not sure what the issue is.

However, since you are defining local functions, you do not need to use sd-call-cmds to call those functions.

Regards

Tom

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It could not achieve my purpose to roll a angle by step pushing the accept button in the dailog window.

Because the dailog window would be closed when I called the local functions without using sd-call-cmds.

Best regards.

Justin

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I went through the program again.

You are calling a modeling function (position_pa). If you call a modeling command like this, without placing it in the (sd-call-cmds) wrapper, it will run the command stop the current command.

(g_test()

(position_pa :part_assembly test_p

:rotate :axis :pt_dir fix_pnt1 (first dir1)

:rotation_angle angle_factor_deg

:done)

should be

(g_test()

(sd-call-cmds (position_pa :part_assembly test_p

:rotate :axis :pt_dir fix_pnt1 (first dir1)

:rotation_angle angle_factor_deg

:done))

Now you do not have to have the sd-call-cmds to call a local function.

I did some editing on the program for myself.

Regards

Tom

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

A quick edit.

I used :minimum and :maximum for a not scaled value. I re-wrote the input to check the angle to keep it in the range of -360 to 360.

Regards

Tom

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As you suggestion I changed the code and then loaded the program.

Result was the same the part roll angle 51.566202° not 0.9°.

When you delete using sd-call-cmds function in the LISP program, load the program,you will find that the part roll 0.9°.

The question I really want to know is why get difference result to roll part using sd-call-cmds and not using it?

Best regards

Justin

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I also found that using sd-call-cmds to call position_pa action you have to assigned :rotation_angle randians value. And not using sd-call-cmds you have to assigned :rotation_angel degree value.You did it the part would be rotated the same angle value.But I really not understand it.

Position_pa action's variable :rotation_angle should be a degree value assigned right?

Best regards

Justin

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Justin

I am not 100% sure of the answer, I can give a best guess. The calculations are done in lisp which requires radians. Modeling takes a degree input and converts it to radians for calculations.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Maybe you are right,but I still do not understand it.

Best regards

Justin