Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: NX -> Pro/E import / conversion?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

NX -> Pro/E import / conversion?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

NX -> Pro/E import / conversion?

Does anyone here have a working knowledge of NX?

I've been provided with some client models in NX format, but as I don't use NX I'm importing them into Pro/E to incorporate in a new assembly, and in some cases to modify - although for illustration rather than manufacture.

I've opened the assembly in NX, exported as STEP, and imported into Pro/E (WF4). In principle this has worked, but many of the more complex parts (cast gearbox casings) have failed to solidify, in one case with myriad tiny gaps, e.g. at the edges around drilled hole points. This is making them rather awkward to modify.

Does anyone know either a) a better way to do the conversion, or b) some settings I can change (probably in the NX export) to improve the STEP accuracy?

IDD isn't an option - I've tried on a couple of models and the Search tool fails to find any gaps; hunting them down manually would take hours, and finding the last ones would be almost impossible.

Thanks!

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

2D Drawing

- Tags:

- step

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, that turned out to have an easier fix: I slackened the Absolute Accuracy from our default of 0.01 (mm) to 0.05. Both the problem parts were suddenly able to be solidified.

Wish I'd tried that one sooner... ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Jonathan

I am not sure, however if you have NX and Pro/E on the same PC, you can open NX geometry directly. (NX.prt)

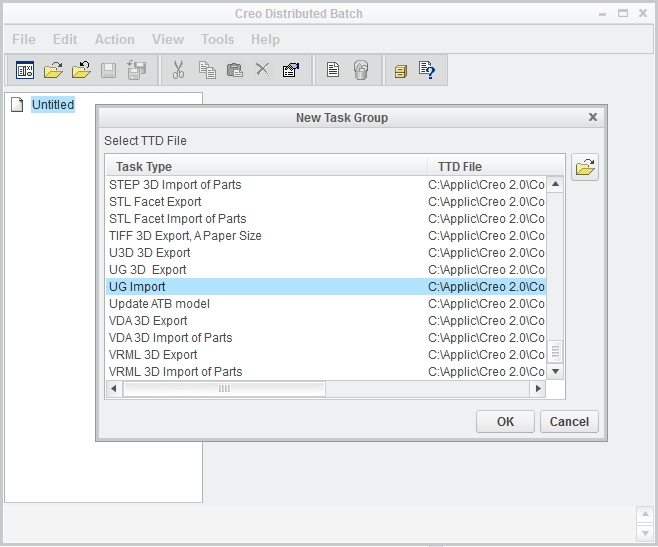

You can try PTC Distributed Batch too.

Regards

Radovan

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Radovan.

I have access to both, but they're network installs running from a licence manager - will that work?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I hope so.

At this time you must have special licence: check http://www.ptc.com/product/creo/interface-for-nx

Check this idea (NX in Creo 3.0)

http://communities.ptc.com/ideas/1477 (copy/paste this link)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ah... we don't have that licence.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

have you tried exporting the items as parasolid files (x_t)? i've had greater success with this than step.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, all depends on export/import settings. Set Retrieve External Accuracy in import process.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Radovan,

Where do I set this? Normally I just open the STEP file and I get no further prompts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

0:19 sec (use Tempalte and set this option).

I hope this works from Wildfire 5.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Just tried exporting one component as Parasolid. It has one missing surface that I can see, and I've just spent the last half hour failing to patch this using IDD. It also has several large holes that appear to be 'skinned over' with geometry that I don't seem to be able to select.

Also, I couldn't make NX export the whole assembly as Parasolid - is this supported?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As I look back through NX parts I've received from clients, it seems that every NX assembly is really a multiple body part, where I have to select each one to export separately. I have no idea why I receive assemblies this way.

I did run a quick test, where I threw two parts together to make an assembly to export as a parasolid. I couldn't seem to select the assembly. I had to select the parts individually, but I could get all of them in one file. Creo did recognize the the parasolid file as an assembly, but it started naming the parts test_1.prt, test_2.prt instead of the names that were used in NX.

My apologies if this wasn't much help. I just try all the options I can before ruling something out.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks, it was worth a try.

I've just tried Parasolid on another, simpler component - but both the STEP import and the Parasolid version refuse to solidify, despite showing no single-sided edges in wireframe view.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have never had problems with NX files unsing STEP 214 format exports. Assemblies have always been exported as assemblies but you do have to select all the components you want to export. There are issues with NX if it is tied to TeamCenter but normally the issues are on import, not export.

If you want me to take a look at your file, let me know. I've healed a few files using Cadkey '99 ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Antonius, but it's customer data so I can't share it.

I've just tried importing into Creo2 but the parts still arrive with tiny gaps. I miss the old (2001?) 'Zip Gaps' function - it wasn't perfect but it was a darn sight easier to do something with than the current IDD.

Radovan, the default accuracy option seemed to be External - I've tried that and Automatic, with neither producing a solidified component.

Oh, and it takes about half an hour to import the STEP each time (flat out on one CPU core). ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, that turned out to have an easier fix: I slackened the Absolute Accuracy from our default of 0.01 (mm) to 0.05. Both the problem parts were suddenly able to be solidified.

Wish I'd tried that one sooner... ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Since there are several places where accuracy is managed; exactly how and where did you set this?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Working in the (already imported and saved as Pro/E) .prt file, Edit->Setup->Accuracy.

Since the import had picked up our start parts, it was already set to Absolute, and changing it from 0.01 to 0.05 fixed the two components I was particularly interested in.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Darn, that is not what I was thinking. I was hoping the import operation had a manageable accuracy setting.

Thank you for clarifying this.