Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Part to unbend

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Part to unbend

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Part to unbend

Hi Everybody,

Please can somebody help me and give me an advise with sheetmetal unbending?

I try to do this in both solid and then convert and sheetmetal, but Creo cant unbend it.

I uses Blend feature to create this shape.

I use Creo Parametric 2.0

Or some advise how i should create it?

Please see attach file.

Thanks for your ineterest.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting: It is a subtle but crucial detail I overlooked in sketch1.

Have a careful look at the construction arc guiding the small radius on the rectangle's corners.

Then look at the construction arc in sketch2. Notice their is no tangent on either construction arcs.

So the problem is that I was trying to twist the surface which could not be unfolded. I suspect there is some tolerance for this, but I exceeded it as soon as the round end was properly defined as representing a true round.

Again, Creo 2 attached.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I find it strangely difficult to make a shape like this in Creo Sheetmetal.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can't test it (so I flattened the quilt), but here's my idea.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Matt, i´m sorry for to late answer. Thank you very much for your idea. This was applicable for me case and i can use it for worst unbend component. One more time thanks.

Michal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I had to give this another try (probably attempt No. 37)... and I was finally successful using a different technique. Probably worth a document!

In this case it was a quilt (1/4) and offset with bend-radii after converting to sheetmetal.

Mirror x3 and merging the seams.

Flat pattern recognized the features.

It is a bit touchy about material thickness but if there is enough margin, no problem.

Creo 2.0 full version attached.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Why is it every time I figure something out, I find a new bug to report ![]()

When I tried correcting "sketch2" to be truly round, the unfold/flat-pattern fails.

I reported this to CS:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting: It is a subtle but crucial detail I overlooked in sketch1.

Have a careful look at the construction arc guiding the small radius on the rectangle's corners.

Then look at the construction arc in sketch2. Notice their is no tangent on either construction arcs.

So the problem is that I was trying to twist the surface which could not be unfolded. I suspect there is some tolerance for this, but I exceeded it as soon as the round end was properly defined as representing a true round.

Again, Creo 2 attached.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is a titbit of information I received from CS...

...You can see this by setting the config option mesh_spline_surf to yes and then setting the model display to Wireframe.

Now my surfaces have a contour type of highlight applied showing they are not strictly planar.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Antonius, thank you very much for answer and iam sorry for to late my answer. I had to stady it at first ![]() But it was cool and i did it.

But it was cool and i did it.

Michal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We love a challenge ![]() Happy to see you got some good ideas.

Happy to see you got some good ideas.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In my opinion it´s waste of time to sketch each bend radius separetly. Maybe you need some marks for bending machine manufacturing ---> create them in unbend state like a sketch and bend it back.

General:

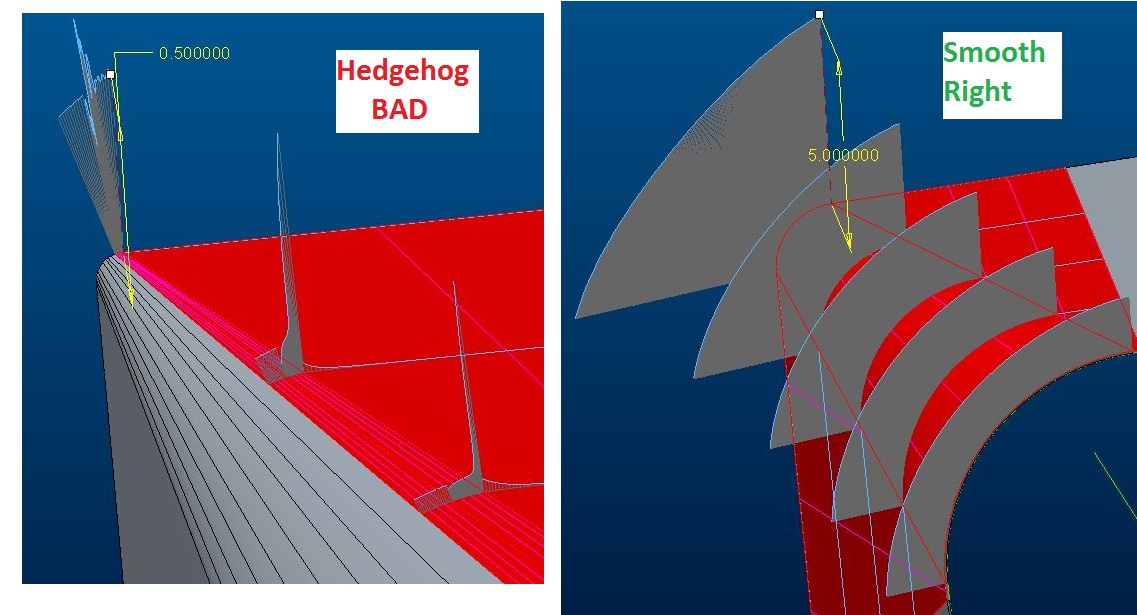

Check curvature of your sheet. Curvature of circle part must looks like a smooth circle, not like a hedgehog ![]() .

.

l was also in fight with thise sheetmetal "duct" transitions. Discovered, that it´s better to use TANGENT condition everyvere in sketch. It´s better than use point align to point and two same radius. Logicaly it´s the same, but Creo works better with tangets conditions in sketch (maybe just my personal feelings).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Funny enough during some recent travels I saw exactly the "hedgehog" pattern on some huge construction beam being transported down the highway.

Remember, we use CAD to do what we want it to do, not what it wants to provide for us ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think the problem is that the original bends are elliptical relative to the faces - take a section normal to the top and side faces and it won't show the bends as true arcs.

I made a demo part with a blocky protrusion, parallel blend; then created the rounds using a variable radius fillet; and finally a sheetmetal conversions with shell to remove the interior. Worked well.

The downside is the slight taper means that while the part flattens OK, the end opening is slightly elliptical.

The perfectly shaped item is a cone (two radii) that is cut at an angle. In my case the cone is tangent to the top and sides. In the original case it is not a true cone, but one that is distorted to an elliptical section.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Brilliant, Steven.

This is the 1st instance where sheetmetal has been able to unfold a tapered bend.

I know it can do cones, but did not realize a blend could be recognized as a bent feature.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Steven,

Thank you for answer and your advice. No edges did´t have to be in transition so i did it.![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you very much everyone for your advices.

Michal