Community Tip - Your Friends List is a way to easily have access to the community members that you interact with the most! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Patterns along Curves - Best Practice

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Patterns along Curves - Best Practice

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Patterns along Curves - Best Practice

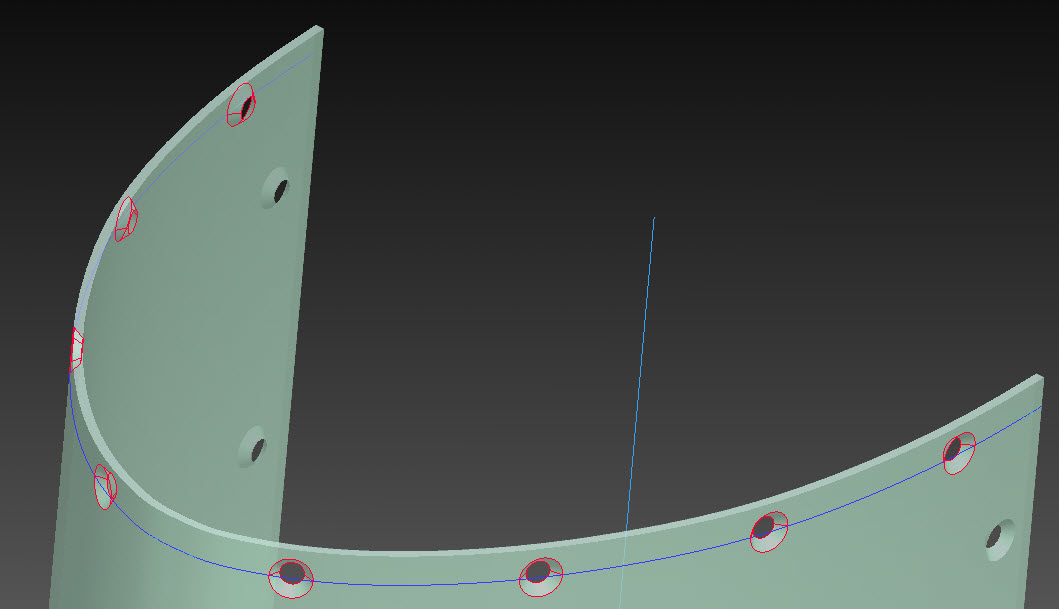

I have a curve, as shown in the picture above, along which I want to pattern some fixing holes.

The patterned holes must line up with matching holes in the part to which this part is fixed.

The obvious way to go (it seems to me) is to create a point on the curve, a distance from the end of the curve, and build the hole feature on that point, then pattern the lot along the curve.

Now here's the difficulty:

I want my holes to be neatly arranged - either the 1st hole should be the same distance from the end of the curve as the last hole is from the other end, or the whole lot should be symmetrical about the mid-point of the curve. (I know they are basically the same, but they are meant to indicate different ways of achieving the same thing. Bear with me...)

I do not have control over the total length of the curve. It will be some weird overall length, like 763.972mm.

I want to have a dimension to show on the drawing that defines the pitch between holes, in terms of distance along the curve - something like '9 holes on 90 pitch'. I am therefore precluded from using the 'Ratio' placement of the point on the curve.

If I start at one end of the curve and pattern the holes along it, I end up playing with the start and pitch dimensions repeatedly until I am happy with the arrangement

The neatest way I have found to achieve this is to create 2 separate patterns of holes, one at the mid-point of the curve and patterned in direction 1, the other starting at one pitch away from the mid-point and patterned in direction 2. Thus, I end up with what I want, BUT there are 2 patterns. I would prefer a single pattern.

How do you do it?

I suppose one answer is that, if I did the one-sided pattern and lived with the untidy hole placement, it would make my part Poka-Yoke! But that is another consideration altogether.

I am sure there is someone out there who has a clever way to solve my predicament. The answer is quite likely staring me in the face!

I am interested to hear your ideas.

Cheers,

John

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

2D Drawing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

John,

I am not sure what you can glean from this, but here a link I had to a patter about a center point/ object, similar to what you are talking about:

http://communities.ptc.com/message/191899#191899

Thanks, Dale

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi John,

could your problem not be solved by relations? You may not have control of the length of curve, but using analysis, measure, length, you know the length. Save this analysis as a feature, & you now have something that could be entered into a relation, to help control your point/hole spacing precisely. Maybe I am missing the point here, & my suggestion is complete rubbish, if so, apologies.

Regards

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think you are looking for skeletons.

You can add a skeleton part to your assembly, which contains data from both parts, and includes the definition of the hole pattern.

Both your parts with the holes get their actual data concerning positioning, number of holes, diameter, ... through the skeleton part via a copy geometry feature.

Adjusting the hole definition in the skeleton part will cause both parts to update, and the holes will always be perfectly alligned.

Jeroen.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

I have created part for you, where I have created analysis feature and some relations.

You can set custom value for two parameters: NUMBER_OF_HOLES and PITCH

System automaticaly create correct offset value for your holes (same offset value from the boundary) ![]()

>> How you can Specifying a Feature in a Relation >>

You can write relations that use the user parameters and manufacturing parameters of a feature.

In a feature relation, you can identify a parameter attached to that feature by the parameter name. For example:

XYZ = parameter_name

where parameter_name is the user parameter.

However, if you write a relation in the feature’s parent model (part or assembly) or in another feature, you must use one of the following formats to reference that feature:

XYZ = parameter_name:fid_N

or

XYZ = parameter_name:fid_feature_name

where:

- parameter_name—the user parameter for the feature.

- N—the internal feature ID (as displayed when you use Info > Feature).

- feature_name—the optional user-defined feature name.

Note: in my example I have created: cl=length:FID_CURVE_LENGTH

Regards,

Vladimir

Vladimir Palffy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

John,

I may be challenged in following your desire - but as I understand it, I wonder if this will work:

The curve can be dimensioned from the edge of the part - and the first hole built on the endpoint of the curve. Then, the last hole of the curve driven pattern will be on the other endpoint of the curve.

Also, I think that in complex mating geometry like you've shown, if using a skeleton to drive the two parts is not an option, you should place your driving curve on the mating surface - that will more easily insure the the hole patterns line up.

Anyone reading this know an easy way to change direction - or swap ends - of a curve driven pattern?

Thanks!

-Nate