- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: ProE thread hole issue

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

ProE thread hole issue

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

ProE thread hole issue

Hi,

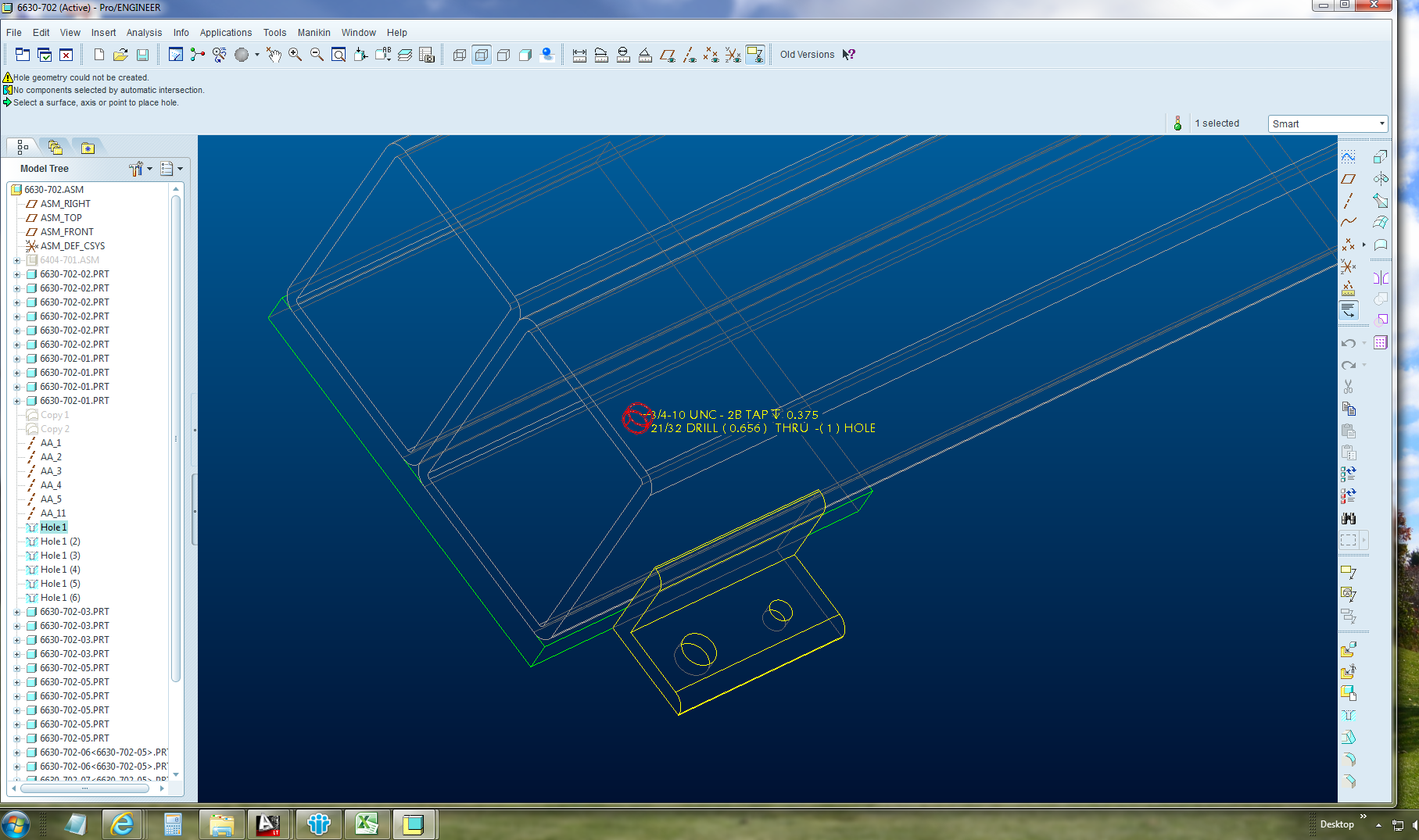

I made 3/4-10 UNC thread hole on the part in assembly:

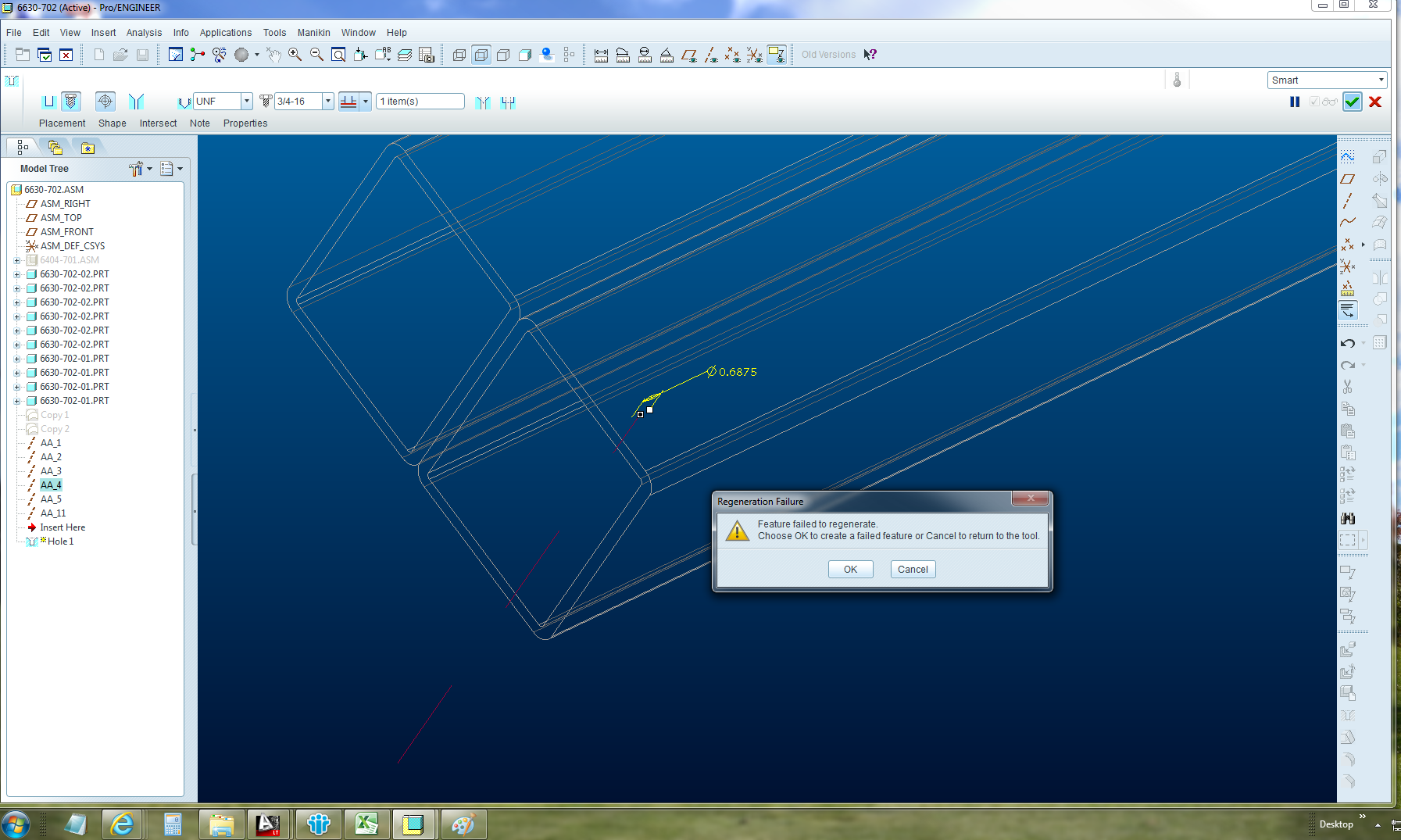

When I want to change thread hole as 3/4-16 UNF, got failue:

Attached file.

Please let me know how to fix this issue, Thanks,

Bill

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

Assembly Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It likely has to do with your hole files. Review your hole table files and make sure that they make sense (ie having a chamfer diameter smaller than the hole diameter would cause a failure).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't open RAR files so I am guessing here, but some of the hole files have 0 in their chamfer values. Review the preview and see if there are errors under options.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Chris, Antonius, where is chamfer setting under hole options? Thanks, Bill

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Shape is one, but you also have to activate the higher level options.

I also noticed you are doing an assembly cut, and that can cause reference issues when you change the hole.

In reality, Creo deletes the previous hole and creates a new one. In this process, some of the previous references are lost.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Antonius, I am using WF5.0, how can I fix it? Thanks, Bill

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Issue was happened on changing hole from UNC to UNF,,, why? Anybody did try on my attached file? Thanks,,,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It is hard to say what is causing the issue. Just know that something in the replacement (literally delete and re-create) is not liking your geometry. Typically this means you have a zero condition between the edge of cylindrical feature and the plane. Creo just doesn't like doing that although I plenty of reasons to need to do this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I did try to re-create hole from UNC to UNF (keep others same) on fresh part and assembly, no any problem. Only happen on this special assembly model, and why?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If all the geometry says this should work, and still fails even on new holes in this one assembly, you should take notice.

Parts and assemblies that start acting strange may well be doing something you really don't want to add more effort to.

A corrupt file may be difficult to work with in the long term. Any subsequent use of the file at next level assemblies or drawings is at risk for both lost time and possible corruption (this is experience speaking!). Worse, it can be propagated to templates or similar design using save-as.

If you suspect a part is corrupt, and you can show how it works in another file, I can only request that you create a support case for the particular problem.

PTC has tools we do not, and they know where to look for simple problems. If you are on maintenance, this is the number one thing to save yourself a lot of trouble in the future. If you do not have maintenance, I highly suggest you start over on this assembly before you dig it too deep into the project. It is just a safety recommendation.

Having said that, if you post the assembly as a BACKUP in zip format, I can open it in Creo 2 and 3 to see if the problem exists in later versions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If I suppress a sub-assembly which is on the top of this assembly, no any issue for creating the UNF thread hole. But when I resume that sub-assembly, the failure appear again. Why?

I can create UNF thread hole on that sub-assembly, no any issue.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In your version, can you select the parts that the assembly cut (hole) is acting on?

Something is line-to-line on the sub-assembly and the cut. This is where Pro|E tends to fail. Typically a tangent.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, I can select the part.

1) For UNC thread holes, no any problem, but UNF.

2) I created this assembly again from scratch, I can make UNF thread holes before I add the sub_assembly. I cannot make it after added this sub-assembly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Could this be an accuracy issue. If your sub assy you are adding is "large" compared to the a feature you are adding, maybe you have a relative accuracy problem.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would guess no since the original hole worked. However, it could be on the edge.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If anybody using WF5.0, try on my attached file please.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In that case, select only the part that requires the hole and don't let it auto-select.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

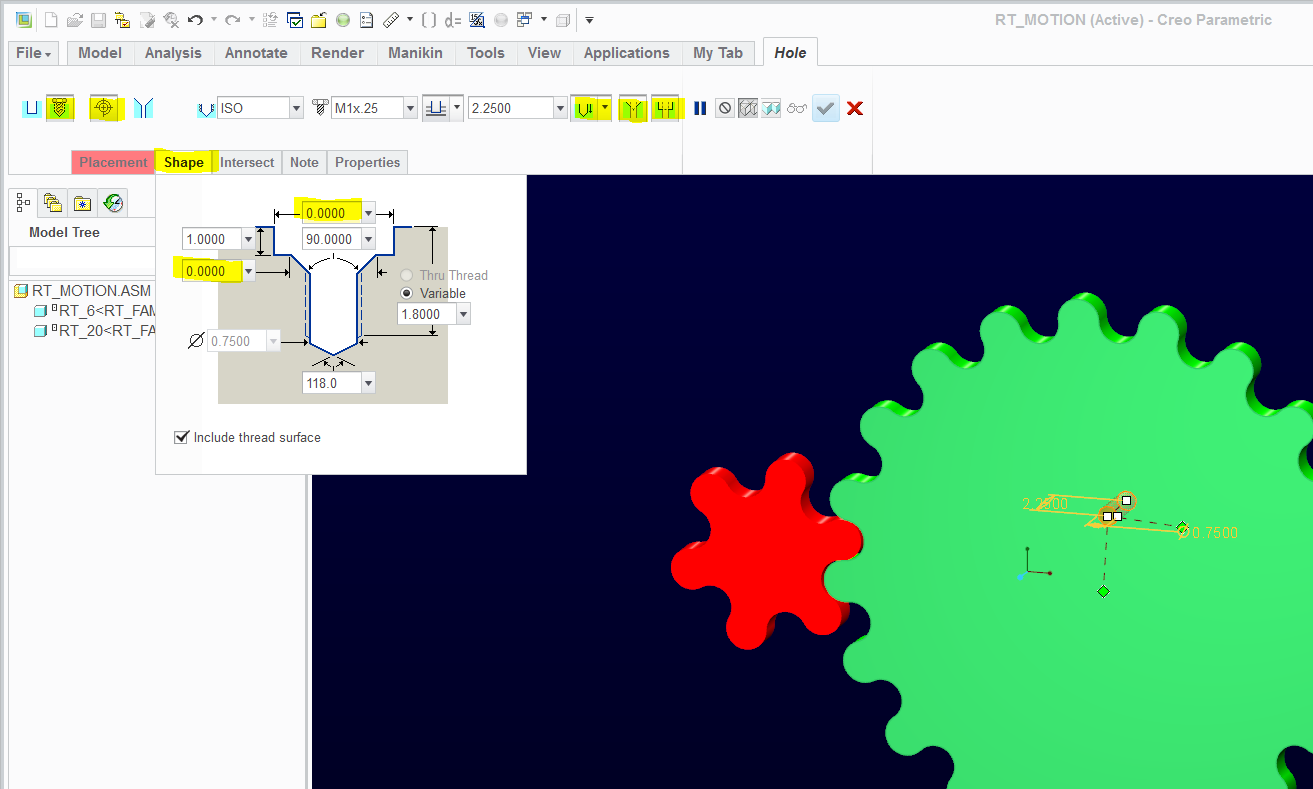

Its accuracy issue.

See attached image for the error.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Stephen and Rabraham, you are right. I changed accuracy to 0.0001 in assembly and sub-assembly, it works. Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Not a good method to follow.

I suggest to add the holes at part level which can be done without changing accuracy.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The holes have to been made on assembly level to match the location of mounting hole which are on sub-assembly.